%&(*%$

Unlike other ,(YD Lincoln uses micro processor con-

trol to monitor and establish the arc without the stick-

ing and shorting of the electrode to the job as seen in

many other ,( installations. Due to the requirement

of the resistance in the circuit to be low, for a ,( to

operate, a good metal-to-metal contact must be made

between the metal core of the electrode and the job.

Any damaged connection anywhere in the output cir-

cuit may limit the operation of the ,(. This includes

a good connection of the work return clamp and the

job. The work return clamp should be connected close

as practical to where the welding will be performed.

Some electrodes form a cone at the end of the elec-

trode after the welding arc has been broken, particu-

larly iron powder and low hydrogen electrodes.

This cone will need to be broken off in order to have

the metal core of the electrode to make contact.

)*(*$*$'+

The starting technique that has successfully overcome

the problem is the push, twist, and peel technique.

This technique requires the operator to push the elec-

trode into the joint and twist.

The Push and Twist breaks off the cone and allows

the metal electrode to make contact.

The peel and lift of the electrode establishes a con-

trolled start to the welding arc. Normal welding tech-

nique for the application is then used.

(!$&(%

The engine used to supply power for your welder is a

heavy duty, industrial engine. It is designed and built

for rugged use. It is very normal for any engine to use

small quantities of oil until the break-in is accom-

plished. Check the oil level twice a day during the

break-in period. In general this takes 50 to 100 hours

of operation.

#&%(*$*

$%((*%%#&")*)(!$*

+$* )%+" )+ * *% ,/

"%)-*$*(*$%*#$

,%"%$"(+$$$&(%)

*/&"+"%$)+#&*%$

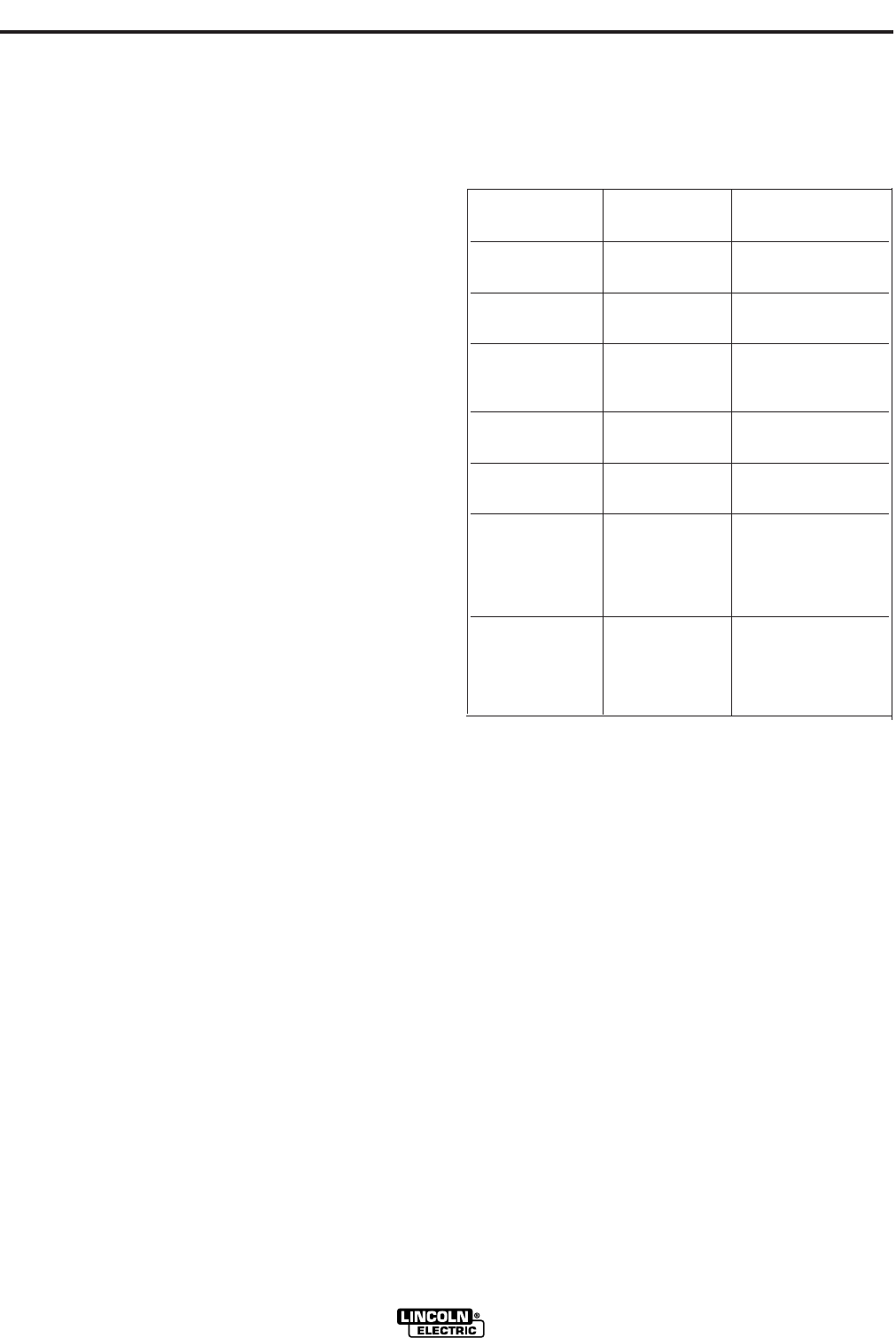

Refer to Table B.1 for typical fuel consumption of the

AIR VANTAGE® 500 (AU) Engine for various operat-

ing settings.

(,$*Q+

$%* This data is for reference only. Fuel consumption is

approximate and can be influenced by many factors, includ-

ing engine maintenance, environmental conditions and fuel

quality.

*23=6

F>>:?D?8:?6F6=@?DF>AE:@?

Cummins B3.3 Running Time for

56HP(42Kw) 25GAL.(94.6L)

@1800 RPM (Hours)

Low Idle - .59 Gal./hour 42.4

no load 1425 RPM (2.2 L/hour)

High Idle - .87 Gal./hour 28.7

no load 1900 RPM (3.3 L/hour)

DC CC Weld 2.10 Gal./hour 11.9

Output 500 (7.9 L/hour)

Amps @ 40 Volts

Auxiliary Power 1.44 Gal./hour 17.4

12,000 VA (5.5 L/hour)

Air Compressor 1.29 Gal./hour 19.4

60 CFM @ 100 PSI (4.9 L/hour)

Air Compressor

60 CFM @ 100 PSI 2.46 Gal./hour 10.2

and DC, CC Weld (9.3 L/hour)

Output 500 Amps

@40 Volts

Air Compressor

60 CFM @ 100 PSI 1.94 Gal./hour 12.9

and Auxiliary Power (7.3 L/hour)

12,000 VA