F-1

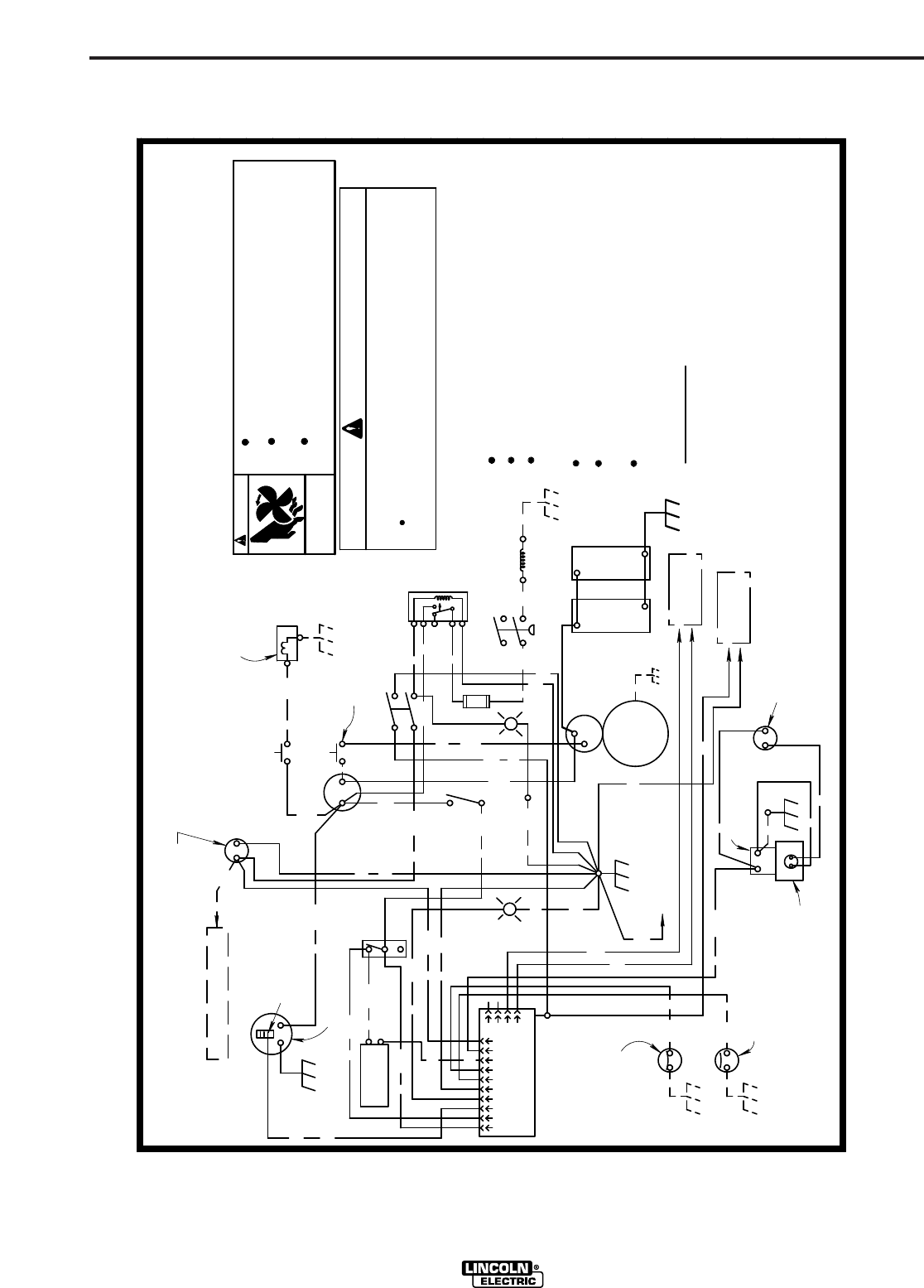

WIRING DIAGRAMS

SAE400 & SAE400 WELD’N AIR

F-1

B

239

Enable

TERMINAL

Compressor

IGNITER

COLD

B

233

THERMOSTART

B

B

-

START

THERMOSTART

230

W

30

B

B

229

B

234

220

B

B

IDLER

SWITCH

IND

J2

PROTECTION

P.C. BOARD

IDLER/ENGINE

J1

+

TO TOROID

2 CR

REED RELAY

R

GROUND SCREW

B

STARTING

Pressure SW.

TO CONTROL PANEL

B

232

G

243

B

SWITCH

240

B

-

WIRING DIAGRAM - SAE-400 WELD'N AIR

236

226

U

231

222

U

S

G

B

228

G

W

R

241

242

B

B

B

R

4

238

G

W

TO FLASHING DIODE

ENGINE HOUR METER

2

3

3

G

B

B

221

G

IGNITION

9

8

5A

7

6

5B

5

1

86

85

87

87a

AS REQUIRED:

DAILY CHECKS:

-

Clutch

Compressor

B

LEAD COLOR CODE

G

-

FUEL INJECTION PUMP

FUEL SHUT

+

TEMPERATURE GAGE

MOTOR

ENGINE TEMP.

SENSOR

B

1

10

G

4

OFF VALVE

+

SWITCH (N.C.)

OIL PRESSURE

+

+

M19232

5C

G

W

R

237

2

ALTERNATOR

SOLENOID

IDLER

GENERAL MAINTENANCE INSTRUCTIONS FOR ENGINE

AND MOTOR DRIVEN ARC WELDING POWER SOURCES.

11-

01

MAINTENANCE INSTRUCTIONS

B

Y

AMMETER

B

Fuse

(10A)

B-BLACK OR GRAY

G-GREEN

N-BROWN

R-RED OR PINK

U-BLUE

W-WHITE

Y-YELLOW

B

235

PARTS

CAN INJURE

MOVING

maintenance work.

maintenance work unless the maintenance work

Keep hands, hair, clothing and tools away

requires it to be running.

Turn the engine or input power OFF before

Have only qualified personnel perform

WARNING:

from moving parts, and insure all guards or

covers are replaced after servicing.

Engine oil, coolant, air cleaner and fuel

All equipment in serviceable condition.

Welding cable connections are tight.

strainer are at proper operating level and clean.

Blow dust from machine using clean low pressure air.

Clean commutators or slip rings with fine sandpaper-

NOT EMERY CLOTH. See Operating Manual for instructions.

Replace brushes before the pigtails are within 1/4"of

the commutator. See Operating Manual for instructions.

WARNING

Uncontrolled release of door restraint cords can cause injury.

Keep secure hold of cord, and keep face away

from cord when hooking or releasing hook.

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual. The

specific diagram for a particular code is pasted inside the machine on one of the enclosure panels.