SP-135 PLUS

E-3

E-3

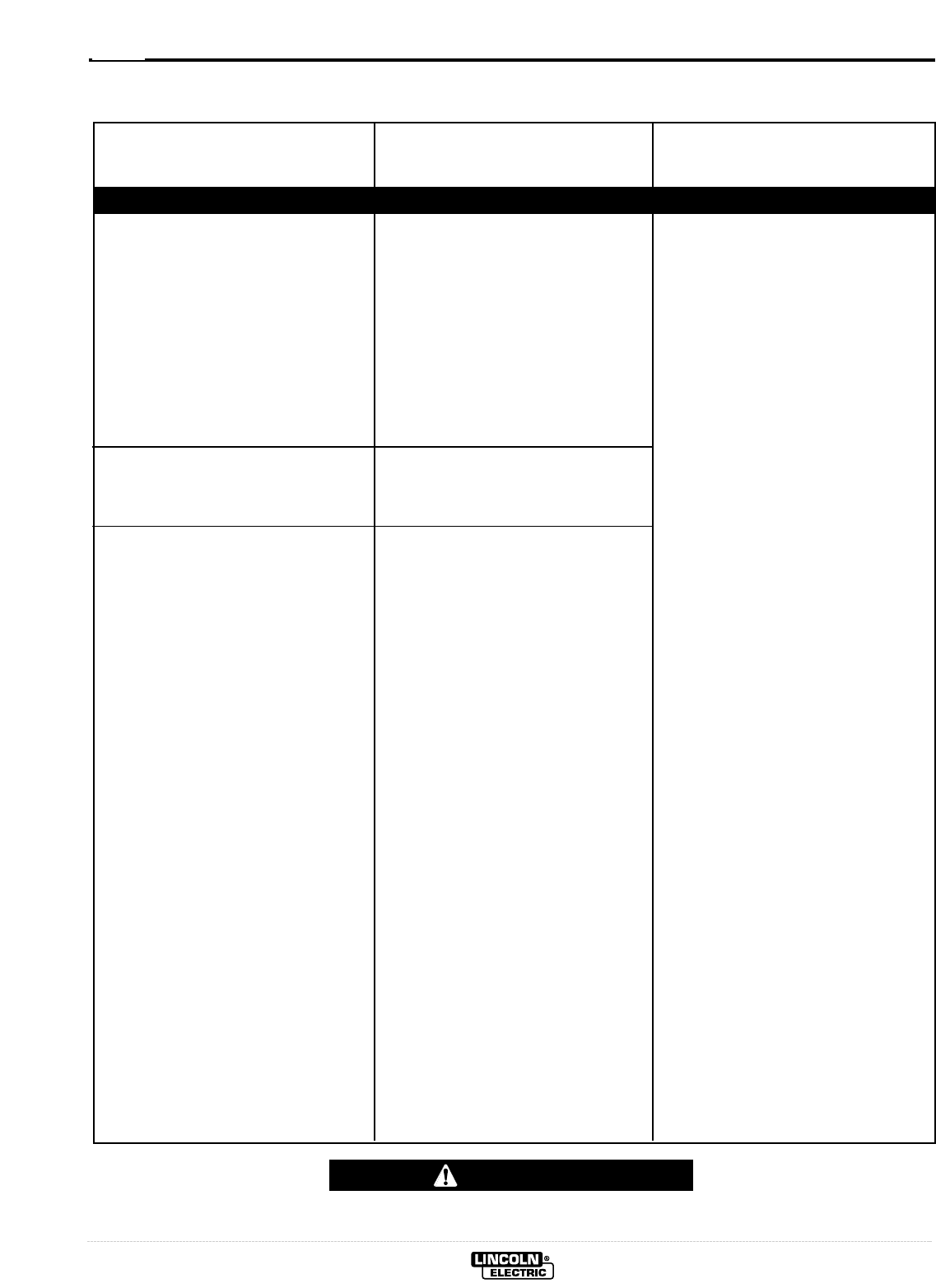

TROUBLESHOOTING

Observe Safety Guidelines

detailed in the beginning of this manual.

TROUBLESHOOTING GUIDE

PROBLEMS

(SYMPTOMS)

No wire feed when gun trigger is

pulled. Fan runs, gas flows and

machine has correct open circuit

voltage (28 vdc maximum) – weld

output.

Wire feed speed motor runs very

fast. Weld output, gas flow and fan

operate normally.

The wire begins to feed butshuts off

after a short time, and will feed

again for anothershort interval only

if the trigger is released and

pressed again. (See description

under wire feed overload protec-

tion).

POSSIBLE AREAS OF

MISADJUSTMENT(S)

1. If the wire drive motor is running

check to see if the correct wire

is in the machine.

2. If the wire drive motor is running

make sure that the correct drive

rolls are installed in the

machine.

3. Check for clogged cable liner or

feeding problems.

1. Make sure that the wire speed

control is not set at maximum.

1. Wire spool friction brake adjust-

ment set too tight. Check adjust-

ment of the wire spool friction

brake. See "Friction Brake

Adjustment" in the "OPERA-

TION" section of this manual.

2. Idle roll pressure adjustment set

too high. Check adjustment of

the idle roll pressure. See "Wire

Threading" in The "OPERA-

TION" section of this manual.

3. Damaged or poorly maintained

wire feed system.

1. Check for clogged or damaged

cable liner, contact tip, and guide

tubes. Replace any damaged or

excessively worn parts.

2. Perform "ROUTINE AND

PERIODIC MAINTENANCE" as

described in this manual.

RECOMMENDED

COURSE OF ACTION

Contact your local Lincoln

Authorized Field Service Facility.

FEEDING PROBLEMS

If for any reason you do not understand the test procedures or are unable to Perform the tests/repairs safely, contact your

LOCAL AUTHORIZED LINCOLN ELECTRIC FIELD SERVICE FACILITY for assistance before you proceed.

CAUTION