,*'-$+ '',!&

##&#!&&*+ !$R(*'

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

$B64?$<A6B?AHG;BE<M87<8?7+8EI<6846<?<GL for technical troubleshooting assistance before you proceed.

-,!'&

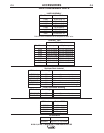

(*'$%+

+1%(,'%+

('++!$

-+

*'%%&

'-*+',!'&

Intermittent wire feed when trigger

is pulled.

Frequent birdnesting or kinking of

wire in the gun cable.

Frequent occurrence of contact tip

burnback.

Poor weld bead appearance.

Wire feeder runs or begins feeding

wire without pulling the gun trigger.

1. Drive roll has become galled.

2. Wire has become kinked along its

feed path.

1. Wire shavings/lubricant is build-

ing up in the cable.

2. Cable liner is too large for wire

size.

3. Mechanical resistance to wire

feeding is too large.

1. Improper welding parameters or

technique (example: ESO is too

short).

2. Wire may be feeding intermittent-

ly.

1. Improper electrode polarity.

2. Improper welding parameters or

technique.

1. Defective trigger (contacts closed

or dirty).

2. Defective (closed) trigger circuit

in the welding machine.

3. Trigger lead(s) inside gun cable

are shorted together or commonly

shorted to either welding or

accessory switch circuits.

1. Remove and then clean or

replace drive roll.

2. Manually pull wire slowly thru gun

until unkinked wire emerges.

1. Clean cable or replace cable

liner.

2. Install the smallest possible liner

which is specified for the wire

being used (i.e. use a .052-1/16

liner instead of a 1/16-5/64 liner

when welding with 1/16” diameter

wire.

3. If using a reverse bend gun tube,

try welding with a non reverse

bend product.

1. See welding wire literature for

proper settings.

2. See symptoms on intermittent or

sluggish wire feed.

1. Reconnect machine’s welding out-

put to proper electrode polarity.

2. See welding wire literature for

proper settings.

1. Replace trigger assembly.

2. See machine’s instruction manu-

al.

3. Damaged control leads along

cable; repair if possible.

Otherwise, replace gun cable.