Py

thon-

P

lus

O

wner's Manual -

P

a

g

e

8

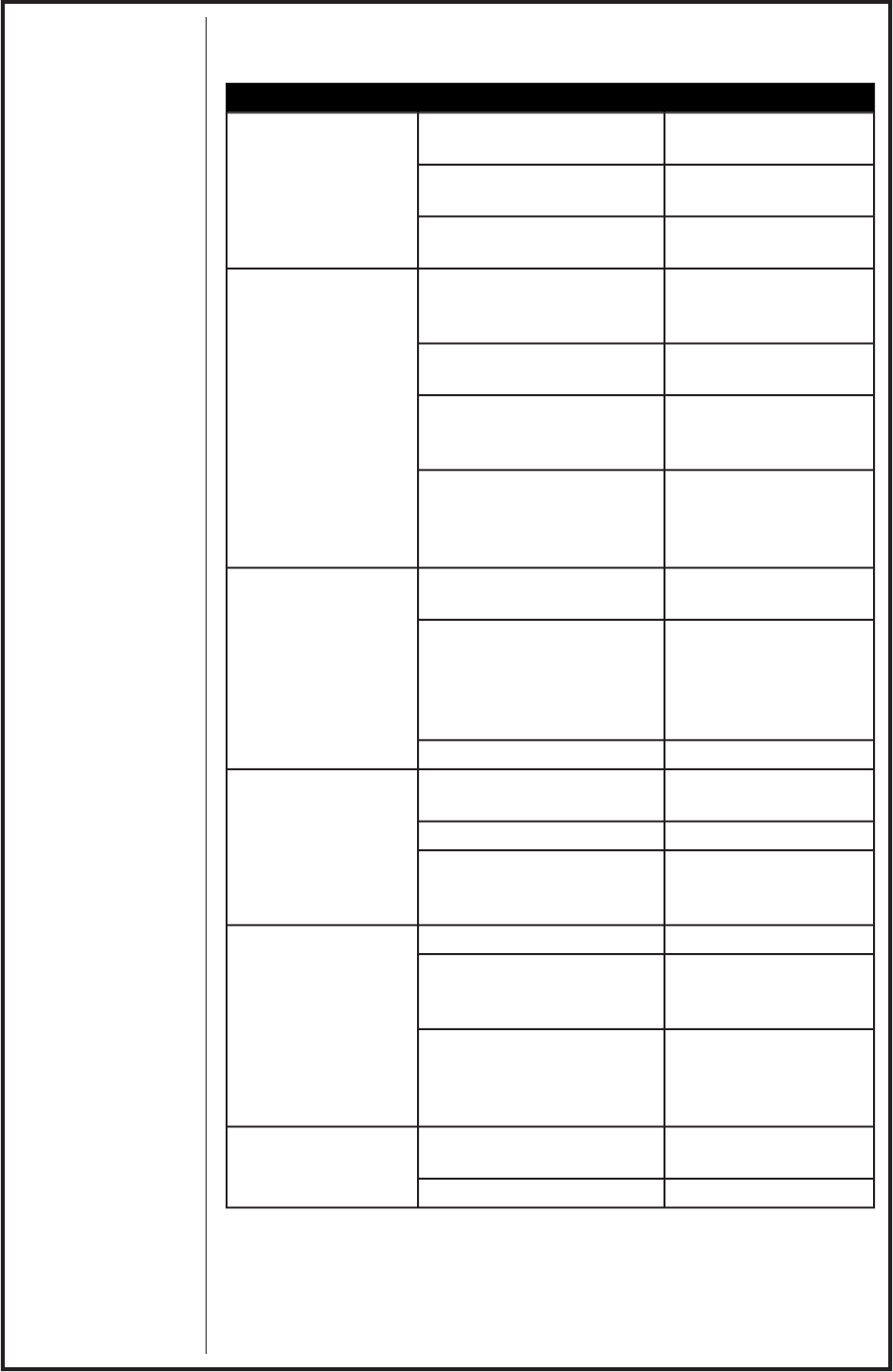

Section E Troubleshooting

Trouble Cause Remedy

N

o wire

f

eed at

t

orch, feeder not

o

perat

i

ng,

i

.e. no

s

lave motor or brake

so

l

e

n

o

i

d

.

115

/

42 VA

C

C

ontrol

f

use in

feeder

/C

ontrol box blown.

R

e

p

lace fuse.

Micro-switch de

f

ective

/

not

bein

g

activated.

R

eplace switch.

C

heck

s

witch for o

p

eration.

Br

o

k

e

n

e

l

ec

tri

ca

l

cab

l

e

.

C

heck micro-switch

wires for continuit

y

.

N

o wire

f

eed at

t

orch, feeder

o

perat

i

ng proper

l

y.

24 VA

C

C

ontrol fuse in

feeder/Control box blown.

C

heck motor leads for

sh

orts; t

h

en re

pl

ace

f

use

.

B

a

d

p

otent

i

ometer

.

C

heck potentiometer

with meter.

Broken Electrical

C

able.

C

heck motor and

potentiometer wires for

c

ont

i

nu

i

ty.

Bad S

p

eed control/PCB

See s

p

ecifi c cabinet

/

c

ontro

l

b

ox owners

manual

f

or speed

c

ontro

l

o

p

erat

i

on.

Wire

f

eeds

,

but

weldin

g

wire is not

energ

i

ze

d

.

L

oose

o

r n

o

cab

l

e

co

nn

ec

t

io

n

s

.

C

heck all

p

ower

co

nn

ec

t

io

n

s

.

C

ontactor control cable

l

oose or

i

n wrong pos

i

t

i

on.

C

heck power suppl

y

o

wners manual for

location and type

o

f contactor si

g

nal

re

q

u

i

re

d

.

W

e

ldi

n

g

power source.

C

heck

p

ower source.

Wir

e

f

eeds

errat

i

ca

ll

y

.

D

irt

y

or worn conduit.

Blow out or re

p

lace

c

on

d

u

i

t.

W

ron

g

s

i

ze contact t

i

p. See Contact ti

p

table.

Idle

r r

oll

s

t

uck

.

C

heck for lock washer

un

d

er

idl

er ro

ll,

or

replace i

f

damaged.

Wir

e

feeds

o

n

e

s

pee

d

on

l

y

.

B

a

d

p

otent

i

ometer

.

C

heck with meter.

B

ro

k

en e

l

ectr

i

ca

l

ca

bl

e.

C

heck

p

otentiometer

wires

f

or continuity or

s

h

o

rt

.

Bad speed control.

S

ee speci

fi

c cabinet

/

co

ntr

o

l

o

wn

e

r

s

m

a

n

ua

l

for s

p

eed control

o

peration.

Wire walks out o

f

d

rive rolls.

Idl

er ro

ll

u

p

s

id

e-

d

own.

Pl

ace groove

i

n

idl

er

roll toward top.

R

ear wire guide missing.

R

eplace wire guide.