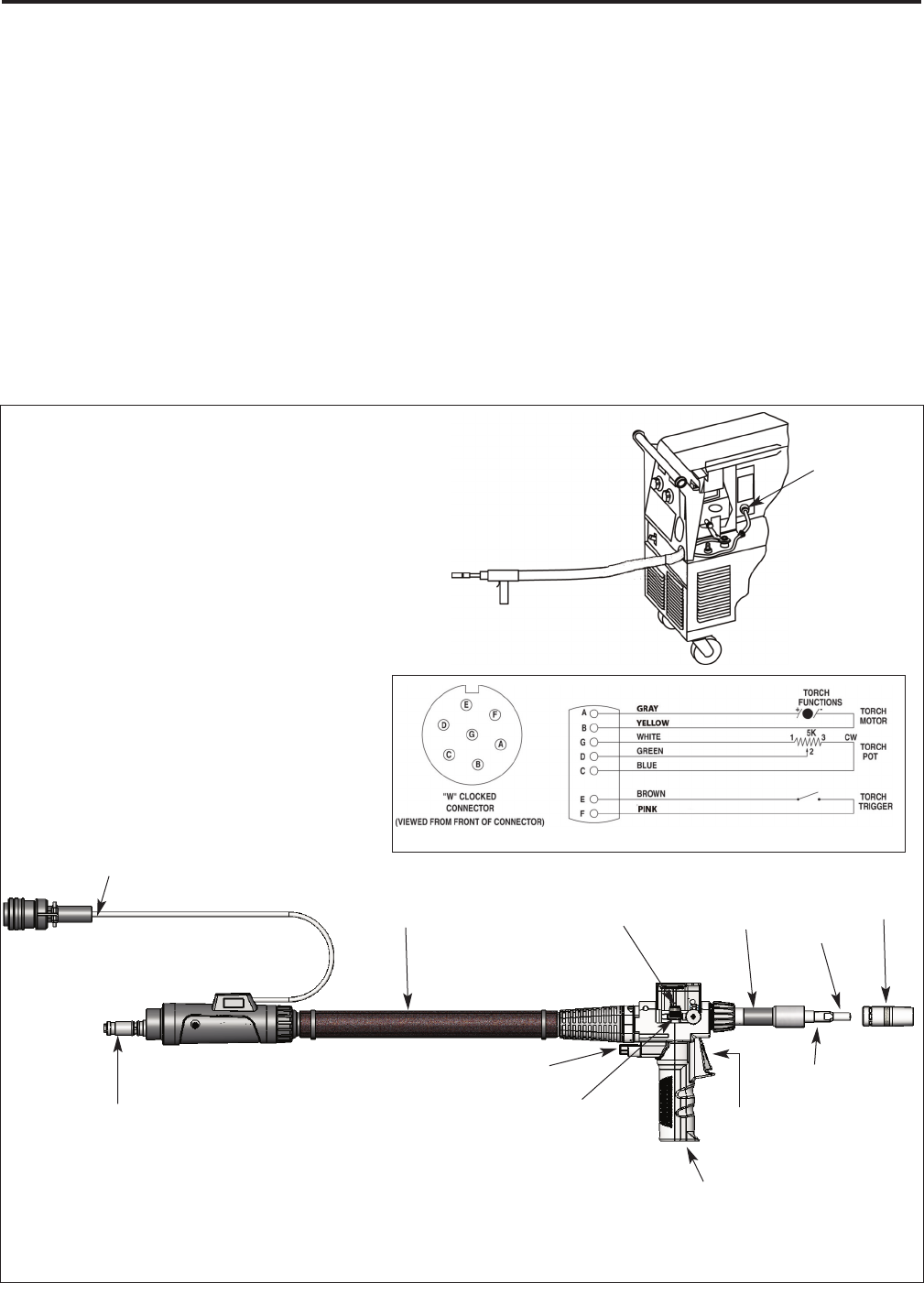

Push-pull Gun Familiarization

Become familiar with your push-pull gun before connecting to

welder. For features described below, refer to Figure on the next

page.

1. Handle, gun can be used in either right or left hand.

2. Trigger operates welding power, gas flow, and wire feed.

3. Remote wire speed control, located behind the handle, con-

trols the speed of the drive motor.

4. Open body cover by flipping lid and observe the following:

a.Wire drive release lever up position moves pressure roller

away from drive roll to stop wire feed. Down position

movespressure roller to wire. Operate wire drive release lever

and see pressure roller move.

b.Drive roll with two wire grooves. Narrow groove feeds .035 (0.9

mm) diameter wire. Wide groove feeds 3/64 inch (1.2 mm)

diameter wire. Gun is shipped with wide groove or 3/64 in

operating position (toward handle). Reverse roller for .035

inch (0.9 mm) diameter wire.

5. Gas nozzle directs gas flow around arc. Unthread gas nozzle to

see contact tip and gas diffuser. Push-pull gun is shipped with

3/64th inch (1.2 mm) contact tip installed.

6. Cable assembly for power, control, and gas. Hold gun and

become familiar with gun's weight and balance.

COUGAR™ Push Pull Gun - INSTALLATION

4

CONTACT

TIP

PRESSURE

ROLLER

(FAR SIDE)

GAS

NOZZLE

TRIGGER

WIRE SPEED

CONTROL

HANDLE

LINCOLN POWER

PLUG

GAS

DIFFUSOR

CABLE

ASSEMBLY

DRIVE ROLL

(NEAR SIDE)

GUN

BARREL

7 PIN AMPHENOL

CONNECTOR

7-PIN

PUSH-PULL

GUN

RECEPTACLE

CONNECTING TO POWER SOURCE:

1. Power source must be “off” and power cord

disconnected.

2. Connect Push-Pull Gun to wire feeder by inserting

power plug to the machine

3. Connect 7-Pin control cable plug to power

source receptacle.

4. Reconnect power and turn on machine.