Safety Precautions

WARNING

• Do not touch electrically live

parts or electrode with skin

or wet clothing

• Insulate yourself from work

and ground.

• Always wear dry insulating

gloves.

ELECTRIC SHOCK

can kill.

• Keep your head out of fumes.

• Use ventilation or exhaust to

remove fumes from breathing

zone.

FUMES AND GASES can be

dangerous.

• Keep flammable material

away.

• Do not weld on containers

that have held combustibles.

WELDING SPARKS can

cause fire or explosion.

• Wear eye, ear and body

protection..

ARC RAYS can burn.

WARNING: Electric shock can kill. Fumes and gases can be

dangerous to your health. Arc rays can injure eyes and burn

skin. See additional warning information under "Arc Welding

Safely Precautions" on inside of front cover of operating manual.

When inching, (the electrode and drive mechanism are always

electrically energized and remain energized several seconds

after the gun trigger is released.

Setup Procedure

Selecting Electrode Wire

Several alloy types of filler metals are available, and the best

choice depends on the type of base metals and the desired

characteristics of the weldment, such as ductility and strength,

corrosion resistance, sustained service temperature, and anodic

treatment color matching. In addition, several wire sizes are

available, and the choice here will depend upon several fac-

tors, including base metal thickness and the arc transfer process

used. Consult your local dealer or appropriate AWS publication

for help in selecting an appropriate alloy type and wire size. Also

refer to, "Procedure Settings" later in this chapter, for wire sizes

used with typical base metal thicknesses and procedure set-

tings.

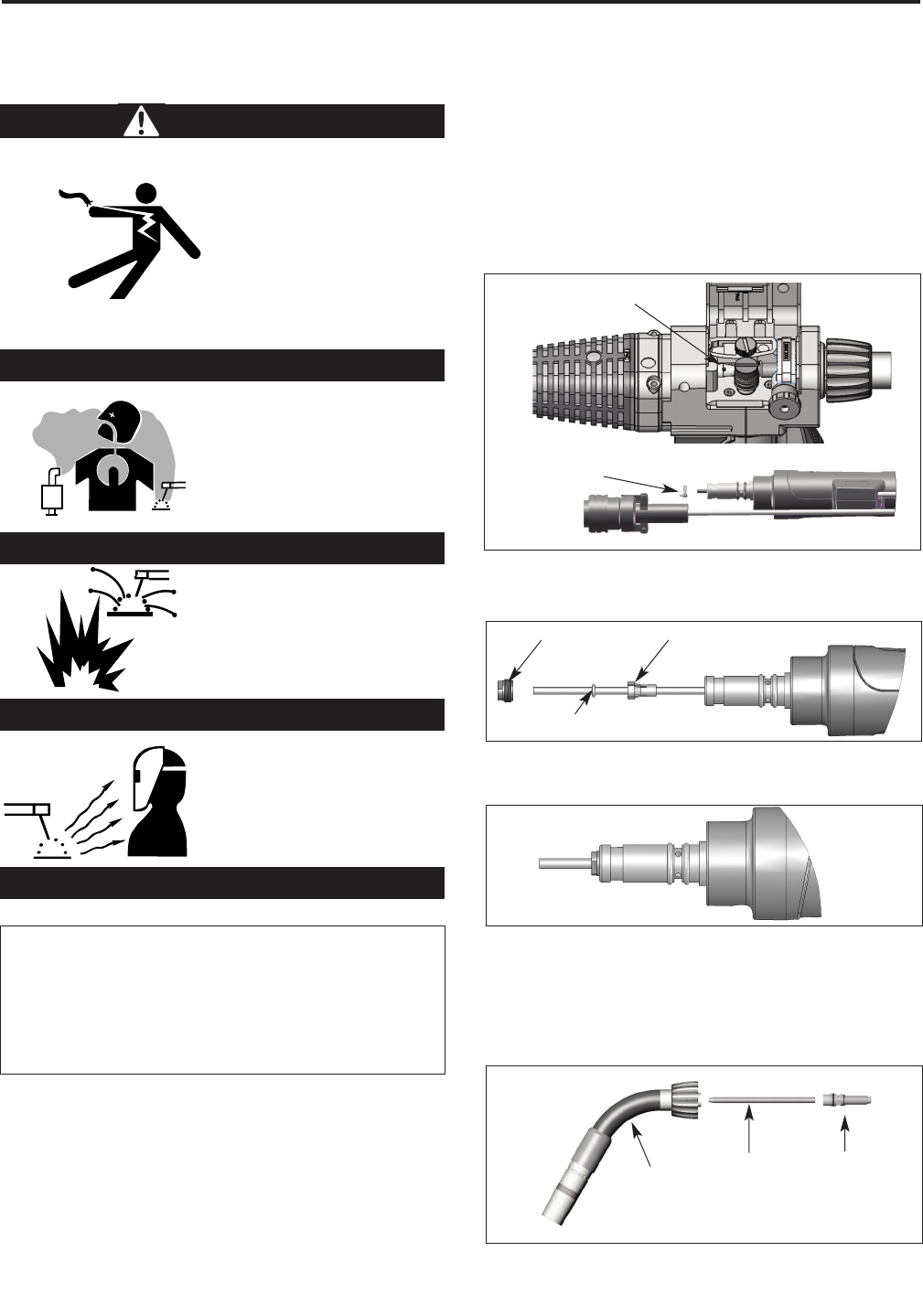

Installing Conduit Liner:

1. Laying torch out straight remove positioning nut, then insert your

liner, tapered end first, all the way into torch until it stops. NOTE:

You should see the liner through the holes in the inlet guide this

will help make sure liner is fully installed.

2. While torch is still laying out straight adjust your O-Ring and col-

let so that they will fit up inside of the power-pin when positioning

nut is installed.

3. Reinstall the positioning nut securely, then trim rest of liner

flush with positioning nut, accordingly to fit up to drive rolls.

Installing Barrel Liner

1. Unscrew barrel inlet guide

2. Unscrew barrel liner from inlet guide

3. Reverse procedure with new liner. Be sure to install liner with

tapered end toward contact tip, and liner is fully threaded into

inlet guide.

Positioning Nut Collet

O-Ring

COUGAR™ Push Pull Gun - OPERATING INSTRUCTIONS

5

Inlet Guide with Liner

Inspection Hole

Liner Positioning

Nut

Torch

Barrel

Neck

Liner

Barrel

Inlet

Guide