B-4 B-4

OPERATION

FEEDING WIRE ELECTRODE

When triggering, the electrode and

drive mechanism are electrically “hot”

relative to work and ground and

remain “hot” several seconds after

the gun trigger is released.

------------------------------------------------------------------------

NOTE: Check that drive rolls, guide plates and gun

parts are proper for the wire size and type being used.

Refer to Table C.1 in Accessories section.

1. Turn the Readi-Reel or spool until the free end of

the electrode is accessible.

2. While securely holding the electrode, cut off the

bent end and straighten the first six inches. (If the

electrode is not properly straightened, it may not

feed properly through the wire drive system).

3. Release the pressure on the idle roll by swinging

the adjustable pressure arm down toward the back

of the machine. Lift the cast idle roll assembly and

allow it to sit in an upright position. Leave the outer

wire guide plate installed. Manually feed the wire

through the incoming guide bushing and through

the guide plates (over the drive roll groove). Push a

sufficient wire length to assure that the wire has fed

into the gun and cable assembly without restriction.

Reposition the adjustable pressure arm to its origi-

nal position to apply pressure to the wire.

4. Press gun trigger to feed the electrode wire through

the gun.

IDLE ROLL PRESSURE SETTING

ELECTRIC SHOCK can kill.

• Turn the input power OFF at the weld-

ing power source before installation or

changing drive rolls and/or guides.

• Do not touch electrically live parts.

• When inching with the gun trigger, electrode

and drive mechanism are "hot" to work and

ground and could remain energized several sec-

onds after the gun trigger is released.

• Only qualified personnel should perform mainte-

nance work.

------------------------------------------------------------------------

The pressure arm controls the amount of force the drive

rolls exert on the wire. Proper adjustment of both pres-

sure arm gives the best welding performance. For best

results, set both pressure arms to the same value.

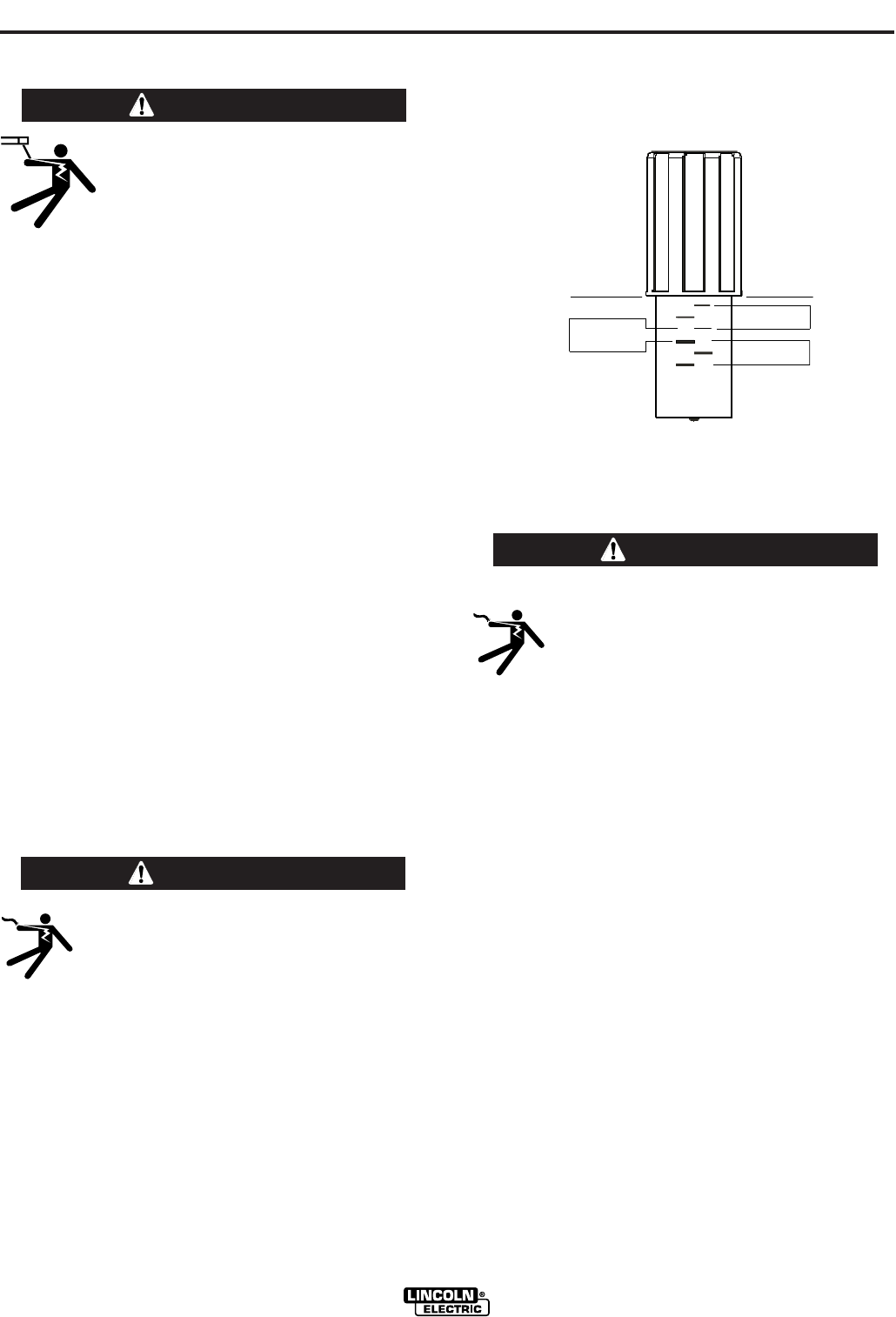

Set the pressure arm as follows (See Figure B.2a):

Aluminum wires between 1 and 3

Cored wires between 3 and 4

Steel, Stainless wires between 4 and 6

WIRE DRIVE CONFIGURATION

(See Figure B.2b)

Changing the Gun Receiver Bushing

ELECTRIC SHOCK can kill.

• Turn the input power OFF at the weld-

ing power source before installation or

changing drive rolls and/or guides.

• Do not touch electrically live parts.

• When inching with the gun trigger, electrode

and drive mechanism are "hot" to work and

ground and could remain energized several sec-

onds after the gun trigger is released.

• Only qualified personnel should perform mainte-

nance work.

-----------------------------------------------------------------------

Tools required:

• 1/4" hex key wrench.

Note: Some gun bushings do not require the use of

the thumb screw.

1. Turn power off at the welding power source.

2. Remove the welding wire from the wire drive.

3. Remove the thumb screw from the wire drive.

4. Remove the welding gun from the wire drive.

WARNING

WARNING

WARNING

POWER MIG 215

ALU MINU M

OUTERSHIELD

METALSHIELD

INN ERSHIELD

STEEL

S

TAINLESS

CORED WIRES

SOLID WIRES

6

1

3

2

5

4