IDEALARC SP-255

E-3

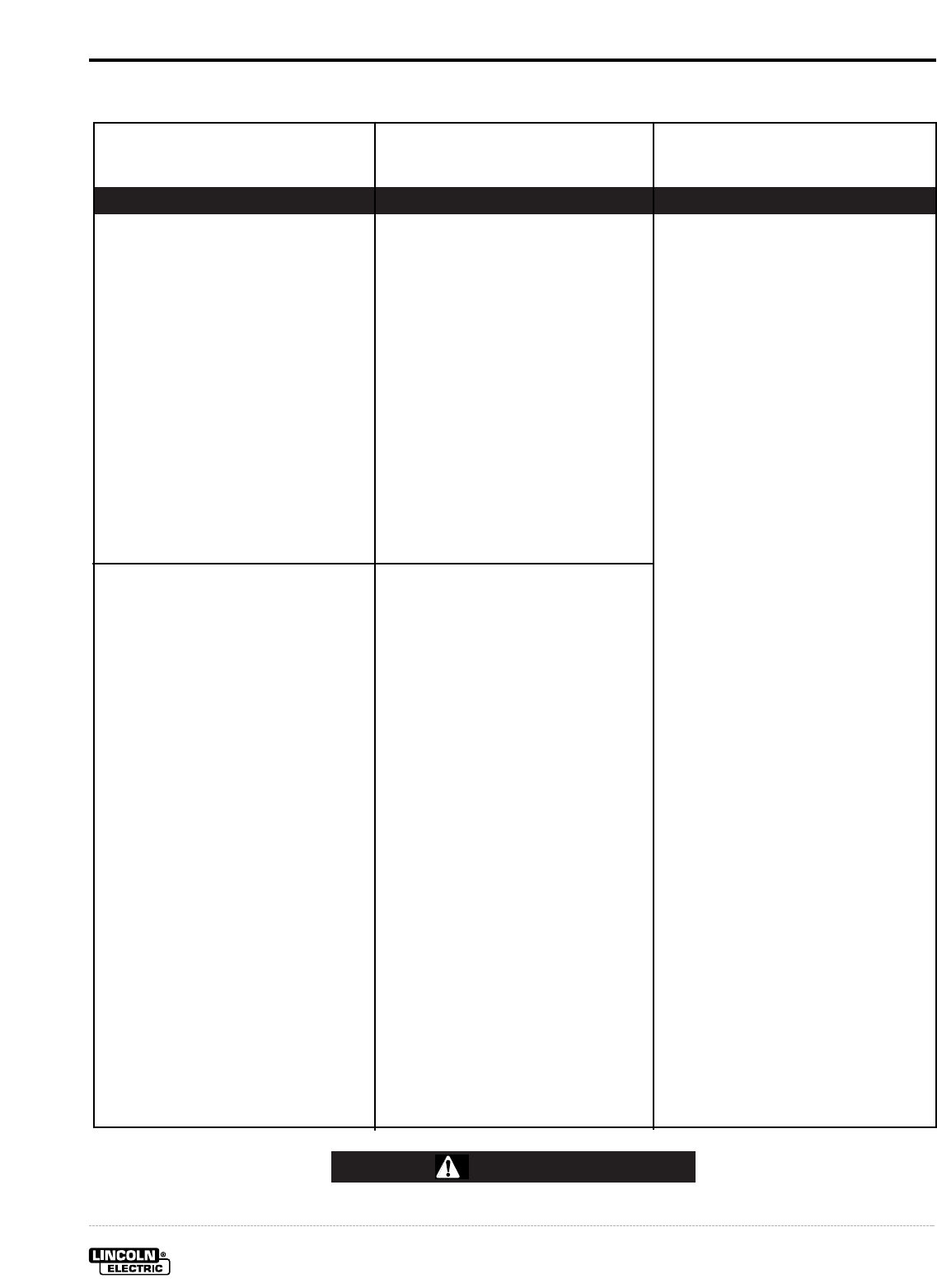

TROUBLESHOOTING

Observe Safety Guidelines

detailed in the beginning of this manual.

TROUBLESHOOTING GUIDE

If for any reason you do not understand the test procedures or are unable to Perform the tests/repairs safely, contact your

LOCAL AUTHORIZED LINCOLN ELECTRIC FIELD SERVICE FACILITY for assistance before you proceed.

CAUTION

PROBLEMS

(SYMPTOMS)

Machine does not put out full

power. Welds are “cold”.

Poor arc striking with electrode

sticking or blasting off.

POSSIBLE AREAS OF

MISADJUSTMENT(S)

1. If “HIGH LINE” or “LOW LINE”

messages are displayed then

check the input voltage. Make

sure input voltage matches

nameplate rating and reconnect

panel configuration.

2. Make sure settings for wire feed

speed and voltage are correct

for process being used.

3. Make sure output polarity is cor-

rect for process being used.

4. Check welding cables and gun

assembly for loose or faulty con-

nections.

1. Make sure settings for wire

speed and voltage are correct

for process being used.

2. The Run-In (Fast or Slow) speed

may be wrong for process and

technique being used. See

Operation section.

3. The Start Voltage may be set

wrong for process and technique

being used. See Operation sec-

tion.

4. The gas shielding may be

improper for process.

RECOMMENDED

COURSE OF ACTION

If all recommended possible areas

of misadjustment have been

checked and the problem persists,

contact your local Lincoln

Authorized Field Service Facility.

OUTPUT PROBLEMS