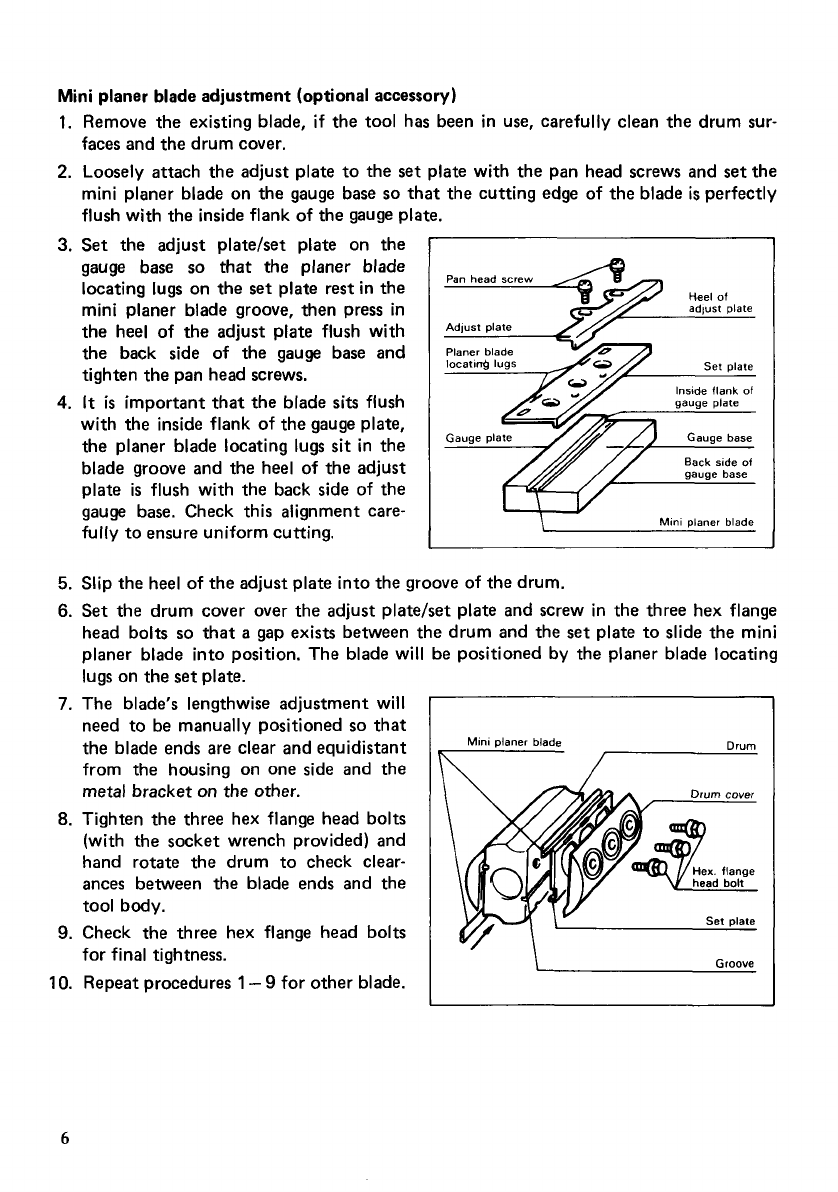

3.

Set

the adjust platehet plate on the

gauge base

so

that the planer blade

locating lugs on the

set

plate rest in the

mini planer blade groove, then press in

the heel of the adjust plate flush with

the back side of the gauge base and

tighten the pan head screws.

4.

It

is

important that the blade sits flush

with the inside flank of the gauge plate,

the planer blade locating lugs

sit

in the

blade groove and the heel of the adjust

plate is flush with the back side of the

gauge base. Check this alignment care-

fully to ensure uniform cutting.

5.

Slip the heel of the adjust plate into the groove of the drum.

6.

Set

the drum cover over the adjust platehet plate and screw in the three hex flange

head bolts

so

that

a

gap exists between the drum and the

set

plate to slide the mini

planer blade into position. The blade will be positioned by the planer blade locating

-

Heel

of

Inside flank

of

lugs on the

set

plate.

7.

The blade’s lengthwise adjustment will

need to be manually positioned

so

that

the blade ends are clear and equidistant

from the housing on one side and the

metal bracket

on

the other.

8.

Tighten the three hex flange head bolts

(with the socket wrench provided) and

hand rotate the drum to check clear-

ances between the blade ends and the

tool body.

9.

Check the three hex flange head bolts

for final tightness.

10.

Repeat procedures

1

-

9

for other blade.

nMini planer

blade

~

D~~~

I

I

Groove

6