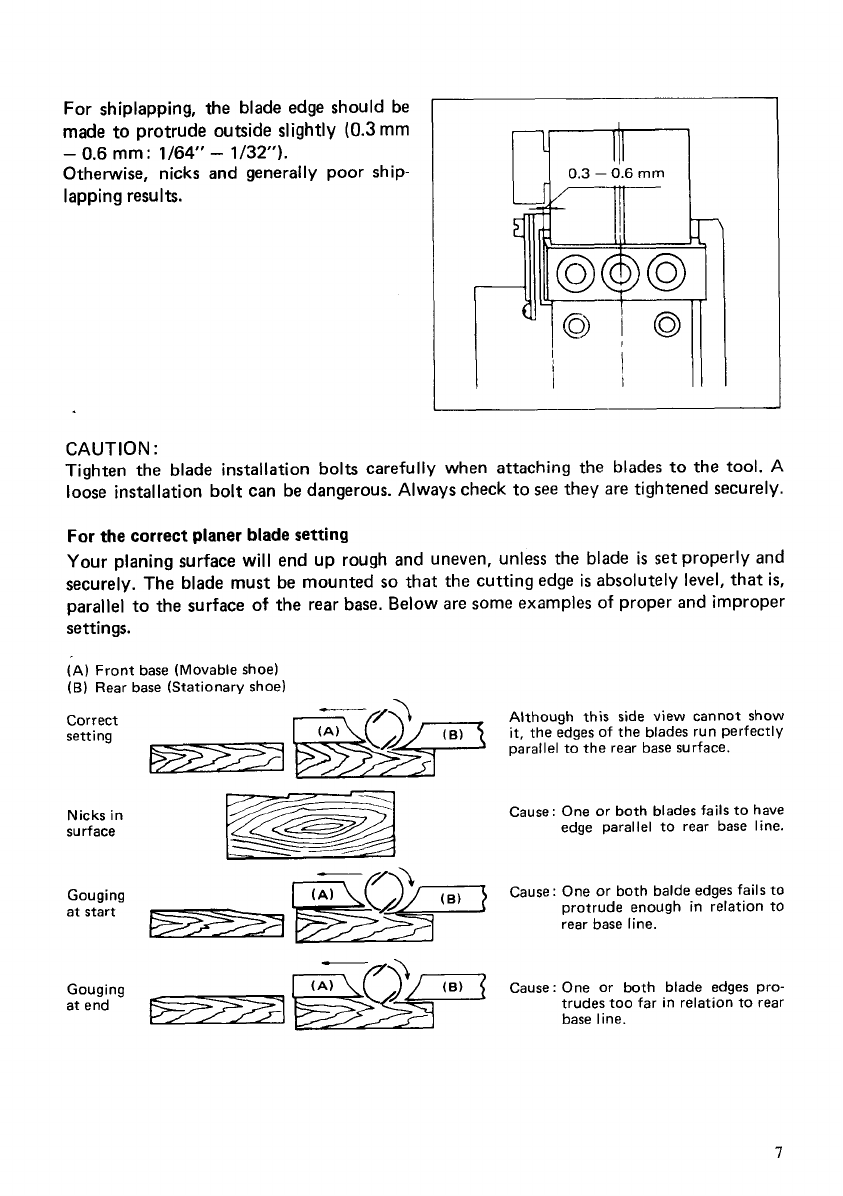

For shiplapping, the blade edge should be

made to protrude outside slightly

(0.3

mm

-

0.6

mm:

1/64"

-

1/32").

Otherwise, nicks and generally poor ship-

lapping results.

I

4

I

I

I

II

CAUTION

:

Tighten the blade installation bolts carefully when attaching the blades to the tool.

A

loose installation bolt can be dangerous. Always check to

see

they are tightened securely.

For

the

correct

planer

blade

setting

Your planing surface will end up rough and uneven, unless the blade

is

set

properly and

securely. The blade must be mounted

so

that the cutting edge

is

absolutely

level,

that

is,

parallel to the surface

of

the

rear

base.

Below are some examples of proper and improper

settings.

(A) Front base (Movable shoe)

(B)

Rear base (Stationary shoe)

Correct

setting

Nicks

in

surface

Gouging

at start

Gouging

at end

Although this side view cannot show

it,

the edges of the blades run perfectly

parallel to the rear base surface.

Cause: One or both blades fails to have

edge parallel to rear base line.

Cause: One or both balde edges fails to

protrude enough

in

relation to

rear base line.

Esg&T(

Cause: One

or

both blade edges pro-

trudes too far

in

relation

to

rear

base line.