8.

Tips on Cutting

This

tool

is equipped with an electric safety brake which stops the saw blade within

three seconds

from

the moment you release the switch

in

the operating handle. This

safety feature can also be used

to

advantage, for example, in cutting certain materials like

light aluminum or plastics where special shapes are required, or

in

edge cuts

in

wood

where only a little stock is cut off. In this case, the saw blade is retracted after the blade

stops, and the

cut

end will not be contacted by a spinning blade as in a regular saw.

Thus,

a cleaner

-

as well as safer

-

cut is p'ossible.

"Always keep the table top clear

of

chips, small pieces and

so

on in order

to

maintain a

safe, clean surface.

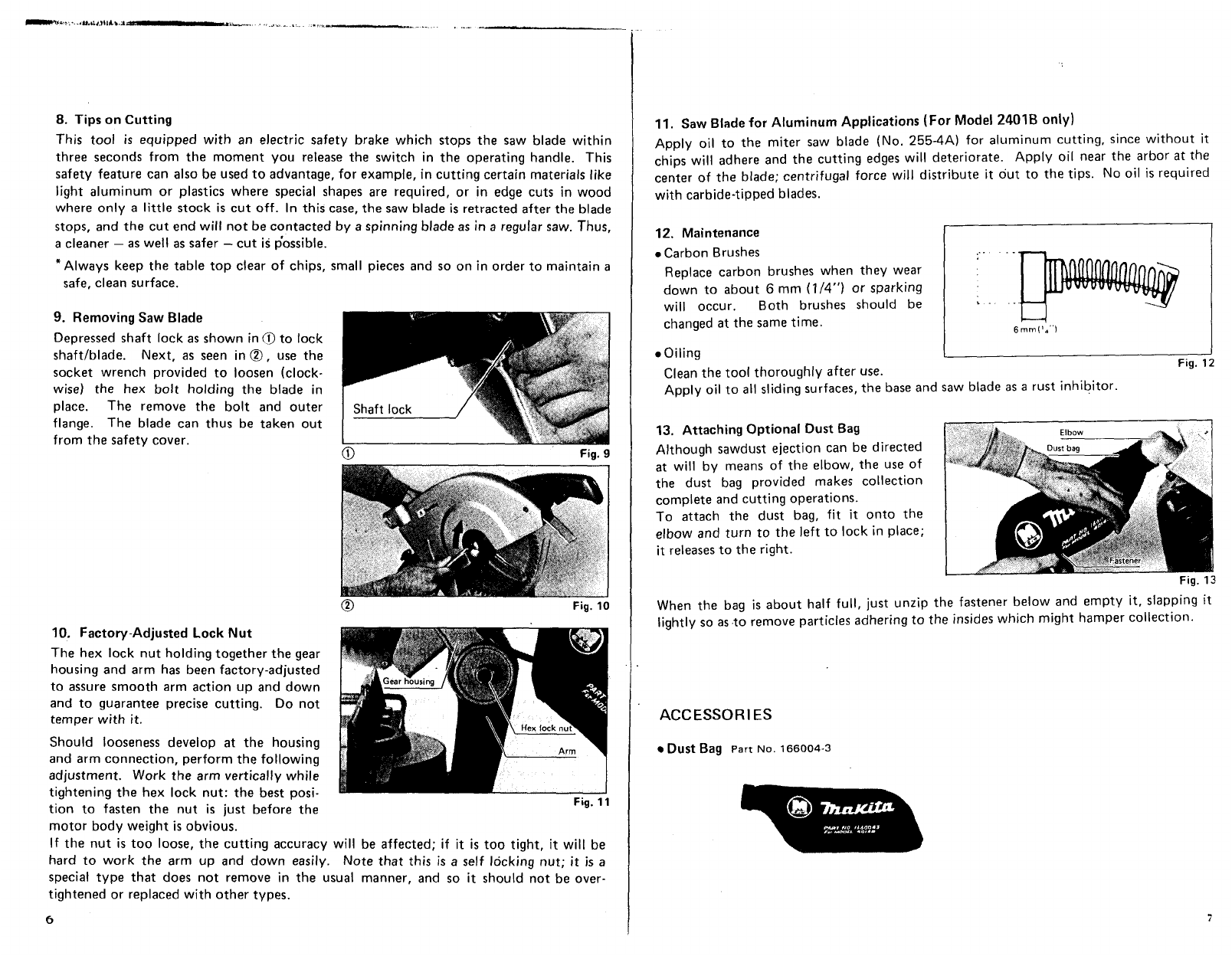

9.

Removing Saw Blade

Depressed shaft lock as shown in

0

to

lock

shaft/blade. Next, as seen in

0,

use the

socket wrench provided

to

loosen (clock-

wise) the hex bolt holding the blade in

place. The remove the bolt and outer

flange. The blade can thus be taken

out

from the safety cover.

10.

Factory-Adjusted Lock Nut

The hex lock nut holding together the gear

housing and arm has been factory-adjusted

to assure smooth arm action up and down

and to guarantee precise cutting.

Do

not

temper with

it.

Should looseness develop at the housing

and arm connection, perform the following

adjustment. Work the arm vertically while

tightening the hex lock nut: the best posi-

tion

to

fasten the nut is just before the

motor body weight is obvious.

I

Shaft

lock

/

0

fig.

9

0

Fig.

10

Fig.

11

If

the nut is too

loose,

the cutting accuracy

will

be affected;

if

it

is

too

tight,

it

will be

hard

to

work the arm up and down easily. Note that this is a

self

locking nut; it

is

a

special type that does not remove in the usual manner, and

so

it

should not be over-

tightened or replaced with other types.

6

11.

Saw Blade

for

Aluminum Applications

(For

Model

2401B

only)

Apply

oil

to

the miter saw blade

(No.

255-4A) for aluminum cutting, since without

it

chips will adhere and the cutting edges will deteriorate. Apply

oil

near the arbor at the

center

of

the blade; centrifugal force will distribute it

out

to

the tips.

No

oil

is required

with carbide-tipped blades.

12.

Maintenance

%

Carbon Brushes

Replace carbon brushes when they wear

down

to

about

6

mm

(1/4")

or sparking

will occur. Both brushes should be

changed

at

the same time.

Oiling

1

Fig.

1

Clean the

tool

thoroughly after use.

Apply

oil

to

all sliding surfaces, the base and saw blade as a rust inhibitor.

13.

Attaching Optional Dust Bag

Although sawdust ejection can be directed

at will by means

of

the elbow, the use

of

the dust bag provided makes collection

complete and cutting operations.

To attach the dust bag,

fit

it

onto the

elbow and turn to the left

to

lock in place;

it

releases

to

the right.

When the bag is about half

full,

just unzip the fastener below and empty

it,

slapping it

lightly

so

as

.to

remove particles adhering

to

the insides which might hamper collection.

ACCESSORIES

Dust Bag

Part

No.

166004-3