Adjusting the fastening torque

The fastening torque can be adjusted infi-

nitely from approx.

5

kg

.

cm

(0.4

ft

.

Ibs) to

37

kg

.

cm

(2.7

ft

.

Ibs).

To adjust

it,

loosen the two screws and turn

the adjusting ring. Then tighten the screws

to secure the adjusting ring. Refer to the

table below fok relation between

the

numbers on the adjusting ring and the

fastening torque to be obtained.

Numbers on adjusting ring

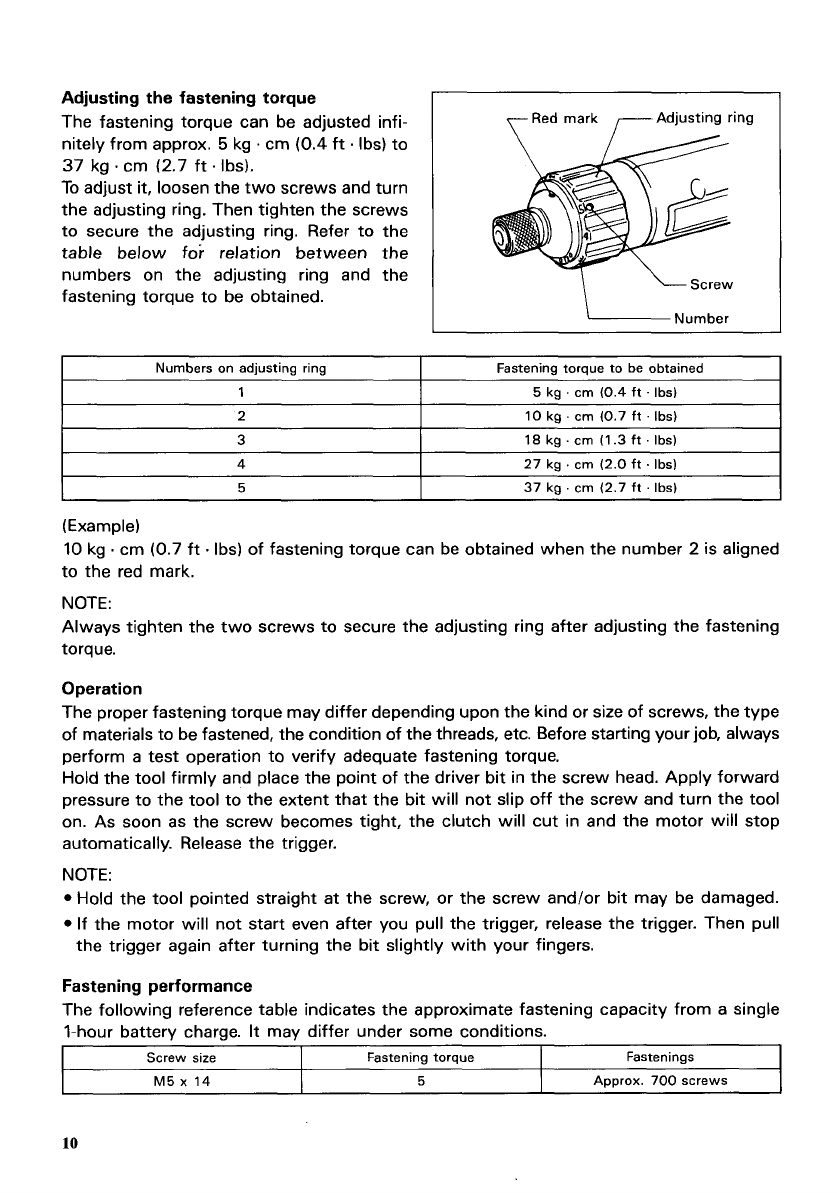

Red mark -Adjusting ring

Fastening torque to be obtained

Screw

Number

1

5

kg

.

cm

(0.4

ft

.

Ibs)

I

2

I

10

kQ

.

cm (0.7 ft

.

Ibs)

I

3

4

5

18

kg

.

cm

(1.3

ft

.

Ibs)

27 kg

.

cm (2.0 ft

.

lbsl

37 kg

.

cm (2.7 ft

.

Ibs)

(Example)

10 kg

.

cm

(0.7

ft

.

Ibs) of fastening torque can be obtained when the number

2

is aligned

to the red mark.

NOTE:

Always tighten the two screws to secure the adjusting ring after adjusting the fastening

torque.

Screw

size

Fastening torque

Operation

The proper fastening torque may differ depending upon the kind or size of screws, the type

of materials to be fastened, the condition of the threads, etc. Before starting your job, always

perform a test operation to verify adequate fastening torque.

Hold the tool firmly and place the point of the driver bit in the screw head. Apply forward

pressure

to

the tool to the extent that the bit will not slip off the screw and turn the tool

on. As soon as the screw becomes tight, the clutch will cut in and the motor will stop

automatically. Release the trigger.

NOTE:

Hold the tool pointed straight at the screw, or the screw and/or bit may be damaged.

If the motor will not start even after you pull the trigger, release the trigger. Then pull

the trigger again after turning the bit slightly with your fingers.

Fastening performance

The following reference table indicates the approximate fastening capacity from a single

Fastenings

I

M5x

14

I

5

I

Approx. 700 screws

I

10