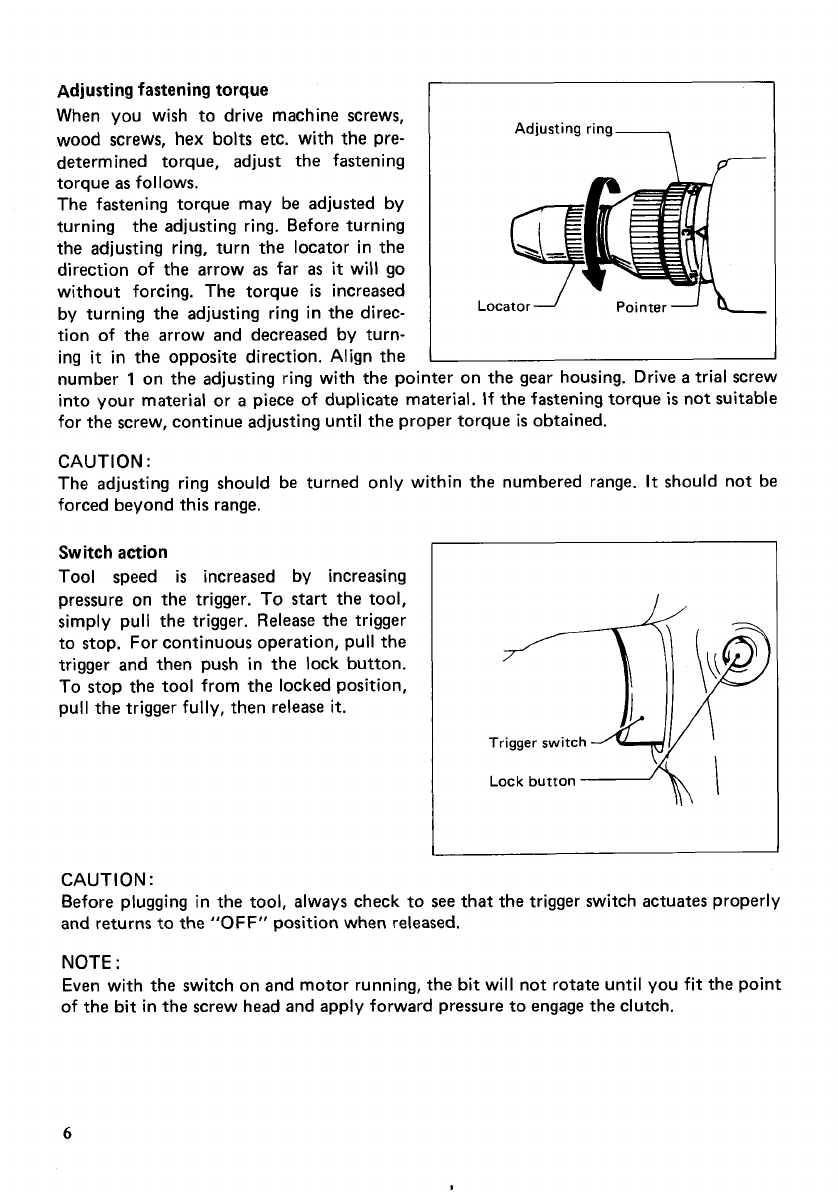

Adjusting fastening torque

When you wish to drive machine screws,

wood screws, hex bolts etc. with the pre-

determined torque, adjust the fastening

torque

as

follows.

The fastening torque may be adjusted by

turning the adjusting ring. Before turning

the adjusting ring, turn the locator in the

direction of the arrow

as

far

as

it

will go

without forcing. The torque

is

increased

by turning the adjusting ring in the direc-

tion of the arrow and decreased by turn-

ing

it

in the opposite direction. Align the

I

number

1

on the adjusting ring with the pointer on the gear housing. Drive

a

trial screw

into your material or

a

piece of duplicate material. If the fastening torque

is

not suitable

for the screw, continue adjusting until the proper torque

is

obtained.

CAUTION

:

The adjusting ring should be turned only within the numbered range.

It

should not be

forced beyond this range.

Switch action

Tool speed

is

increased by increasing

pressure on the trigger. To start the tool,

simply pull the trigger.

Release

the trigger

to stop. For continuous operation, pull the

trigger and then push in the lock button.

To stop the tool from the locked position,

pull the trigger fully, then release

it.

I

Trigger

switch

Lock

button

I

CAUTION

:

Before plugging in the tool, always check to

see

that the trigger switch actuates properly

and returns to

the

"OFF"

position when released.

NOTE

:

Even with the switch on and motor running, the bit will not rotate until you fit the point

of

the bit in the screw head and apply forward pressure to engage the clutch.

6