24

11.6 Tenons and Slots

- To cut tenons and slots a push block is required as shown in paragraph 8. The recess in the push block has to match the

workpiece.

- The riving knife must be installed.

Cutting:

Guide workpiece along the rip fence with your right hand. The left hand, holding the push block, feeds the work into the blade,

keeping it from tilting and twisting. When the cut is completed pull back both workpiece and push block clear of the blade.

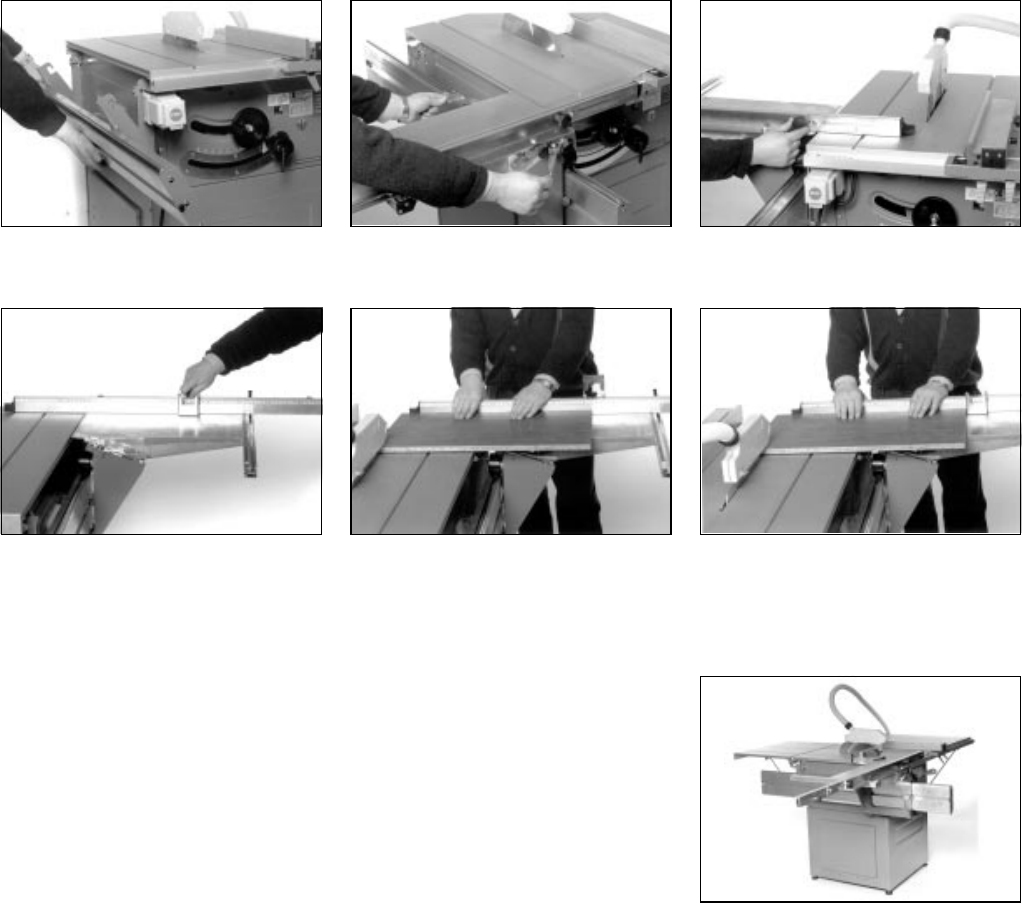

11.9 Dimensioning with the Optional Accessory Sliding Carriage

- For dimensioning have the riving knife and blade guard installed.

Hang roller carriage extrusion into

crosshead plates.

Place table onto traversing saddle and

secure with locking levers.

Set fence extrusion closely against the

blade, tighten starknobs.

Use tape or stick measure to set flipstop to

desired width.

Swing flipstop up and place workpiece on

table.

Start saw and square workpiece.

Pull sliding carriage back.

Turn work around by 180°, swing flipstop

down again and place squared edge

against the stop.

Make second cut.

When dimensioning large panels, which are not adequately supported by the saw table,

install the table rear and/or table side extension, available as optional extras, for

additional support.

11.7 Cutting the Tenon Shoulder

To cut the shoulder of the tenon always use the mitre fence or the sliding carriage, available as optional accessory.

- The riving knife must be installed.

- Have auxiliary fence installed on rip fence and positioned for crosscuts.

11.8 Cutting Wedges

Cut wedges only with a wedge cutting jig made for the wedge dimensions as described in paragraph 8.

- Have riving knife and saw blade guard installed.

With the right hand guide the wedge cutting jig along the rip fence until the wedge is clear of the riving knife. The left hand

keeps the waste clear of the blade (use push stick if waste is small to keep hand clear of blade).