25

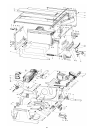

Tilt machine to the rear and rest on rear

housing panel to have access to the chip

case.

Loosen the two bolts size M 12, holding

the chip case, by 1/2 turn.

Remove table insert and chip case lid.

Loosen counter nuts M6 on the swivel

trunnions and adjust saw blade position by

turning the nuts as required, until blade

runs clear of the table's edge.

Important!

Make sure that all screws and nuts are

retightened after setting.

12 Adjusting the Saw Blade Position

The saw blade is factory set to a centre position in the table slot. Use of saw blades with wider teeth may require a resetting

of the blade position

14.1 Tool Maintenance

Residue resin built-up on the saw blades should be removed regularly. Immerse blade(s) in a sodium carbonate solution, or

in a parafin/kerosene solution or mineral turpentine for 24 hours. The residue resin can then be easily wiped off with a rag.

Clean blades improve performance and cut quality.

14 Care and Maintenance

- Always disconnect from power before servicing.

This machine is designed to require only minimal maintenance. It is recommended to protect it from high humidity, rain and

agressive agents, such as acid vapors or solvents. All bearings and threaded rods, as well as the extrusions supporting the

rip fence, should regularly given a light coating with gun oil.

To ensure smooth operation clean the threaded rod (218) of the main blade's rise and fall mechanism regularly with kerosene,

then give a light coat of oil to the spindle and bearing. Keep saw blades from rust.

Regularly clean the motor's cooling fins from dust to ensure sufficient cooling.

Note

Both single-phase and 3-phase motors supplied with this saw are equipped with a mechanical motor brake designed for a

long service life. However, friction causes the brake pad to wear. If the blade needs more than 10 sec. to come to a complete

standstill the motor brake has to be replaced. Contact your dealer or a authorized service centre for help.

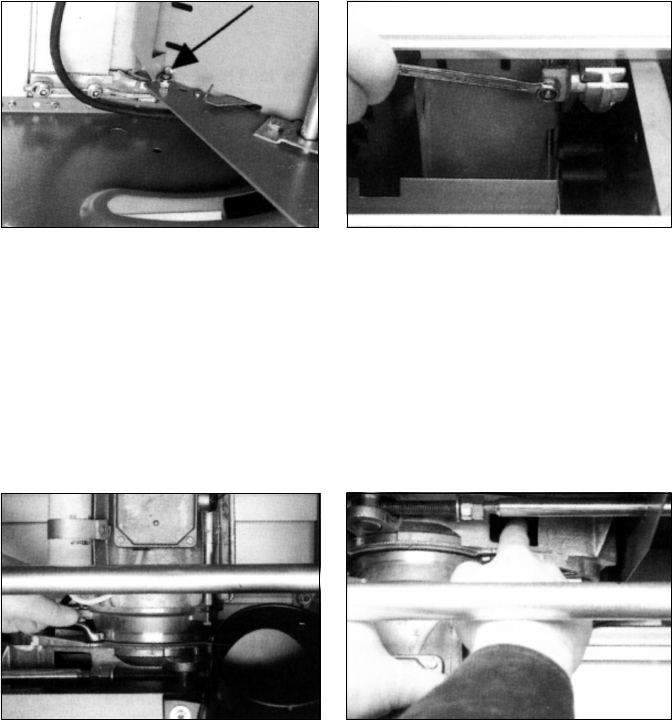

13 Belt Tension

Disconnect from power before servicing!

To set belt tension loosen the 4 motor

mounting screws one full turn.

Turn motor to tighten belt. The belt tension

can be checked through the opening in the

transmission housing. Slack should be

approx. 5 mm.