OM-1500-1 Page 15

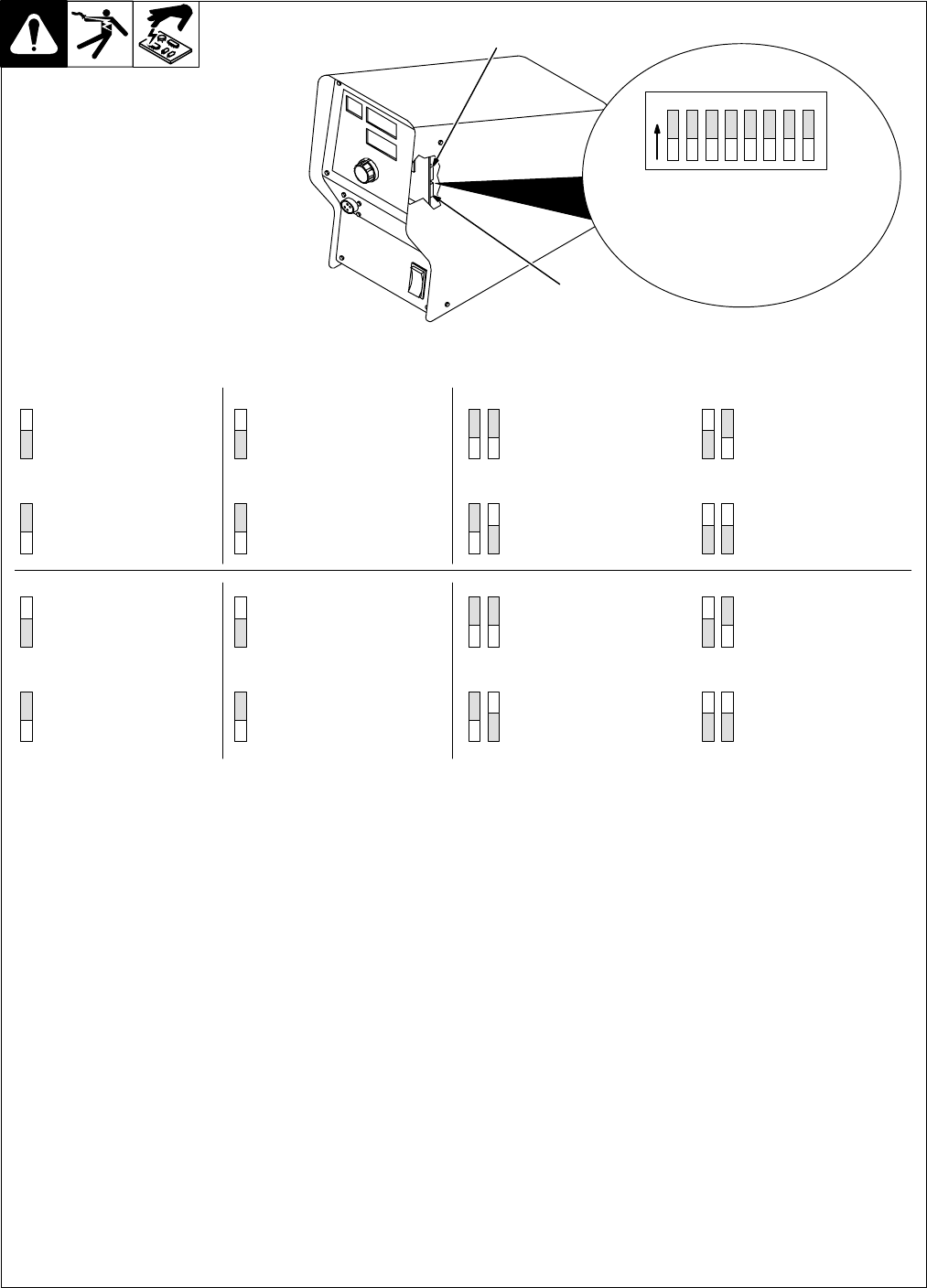

4-7. Setting Internal DIP Switches

1 DIP Switch S1

2 DIP Switch S4 (Not For Customer Use)

DIP switch S1 allows the user to make a num-

ber of choices affecting unit operation.

w Selecting Weld Amperage Or Wire Feed

Speed Display (S1-1)

If the front panel DIP is set in the display amps

position, the lower display (see Section 5-6)

shows amperage while the unit is welding at

an amperage value above 25 Amps and the

current detect override is in the Off position. If

the amperage display position is not used, the

lower display shows wire speed.

w Selecting Wire Feed Speed Value (S1-2)

The unit displays wire speed in units of inches

per minute (IPM) if the English/Metric wire

feed display DIP is in the English position. The

unit displays wire speed in meters per minute

(MPM) if the DIP is in the metric position.

w Adjusting Range Limits (S1-3 & 4)

The lock feature provides a means of regulat-

ing unit settings, but still allows some level of

adjustment through the Adjust control. When

a lock position is used, the lock applies to all

programs. Two DIP switches are dedicated to

locking unit settings. Four possible combina-

tions of the two DIP switches provide the fol-

lowing settings: Locks Off, Locks On ±5%,

Locks On ±10%, and finally Locks On ±20%.

If the wire speed is at 300 IPM when the lock

DIP is activated, and the lock range is set at

±10%, the operator would have an adjustment

range from 270 to 330 IPM.

. To changing Lock %, proceed as follows:

Turn power Off

Place DIP switches S1-3&4 in the Off position

(see *3&4 above)

Turn power On and Off

Place switches 3&4 in desired new settings

Turn power On and Off.

Trigger Hold and Dual Schedule function nor-

mally when locks are enabled.

w Setting Display Hold Feature (S1-5)

If the display hold DIP is in the “Hold On” posi-

tion, the unit will hold the last weld information

for 5 seconds following weld termination. If

any front panel push button is pressed, or if the

Adjust control is activated, the display hold

feature is terminated.

w Setting Current Detect Override (S1-6)

Current detect override is used to disable run-

in when a welding power source is used that

doesn’t provide current feedback through the

14-pin receptacle.

w Defining Motor Speed (S1-7 & 8)

Switches 7 and 8 allow the user to define

whether the motor in use is normal speed

(50–780 inches per minute) or high speed

(90–1440 inches per minute).

802 808

1

2

12345678

O

N

1

2

34

5

678

2

1 34

5

6

78

34

34

7878

Position Settings And Results For DIP Switch S1

On = Front panel display

shows weld amperage

during welding.

Off = Front panel display

shows wire feed speed

during welding.

On = Front panel display

shows wire feed speed in

meters per minute.

Off = Front panel display

shows wire feed speed in

inches per minute.

3 On, 4 Off = Range limit

on voltage and wire feed

speed set at ±5%.

3 Off, 4 Off = Range limit-

ing disabled (locks Off).

3 On, 4 On = Range limit

on voltage and wire feed

speed set at ±20%.

3 Off, 4 On = Range limit

on voltage and wire feed

speed set at ±10%.

On = Front panel display

holds weld parameters

for 5 seconds following

trigger release.

Off = Front panel display

returns to preset upon trig-

ger release.

On = Current detect overri-

de. For welding power

sources that don’t provide

current feedback through

the 14-pin receptacle.

Off = Current must be de-

tected to go from run-in to

welding condition.

7 On, 8 Off = Reserved

for future use.

7 Off, 8 Off = Normal

speed motor (50–780

inches per minute)

7 On, 8 On = Reserved

for future use.

7 Off, 8 On = High speed

motor (90–1440 inches

per minute)

. In the DIP switch S1 illustrations,

the elevated slider on each switch

is show in white. For example, the

switches above are all in the Off

position.

. When DIP switch positions are changed, the

unit must be turned Off and then On again in

order for the new settings to be active. DIP

switches are only read on power up.

*