OM-1580 Page 7

3-2. Outlet Cable, Weld Cable, And Gas Connections

Ref. ST-156 544

1 Outlet Cable Securing Knob

2 Outlet Cable Opening

3 Outlet Cable End

Loosen knob. Insert outlet cable

end into opening. Position as close

as possible to drive rolls without

touching. Tighten knob.

Connect 4-pin plug from outlet cable

to the 4-socket receptacle on the

motor mounting bracket.

4 Weld Cable Terminal

5 Weld Cable

Select and prepare weld cable ac-

cording to welding power source

Owner’s Manual.

6 Shielding Gas Fitting

7 Gas Hose

Gas fitting is located behind outlet

cable opening.

Connect gas hose from fitting on ro-

bot to shielding gas fitting on wire

drive assembly.

6

9/16 in

Tools Needed:

Connect To

Gas Fitting

7

Connect To Positive (+) Weld

Output Terminal On Welding

Power Source For Reverse

Polarity Weld Process Or

Connect To Negative (–) Weld

Output Terminal On Welding

Power Source For Straight

Polarity Weld Process.

4

5

1

2

3

On Robot

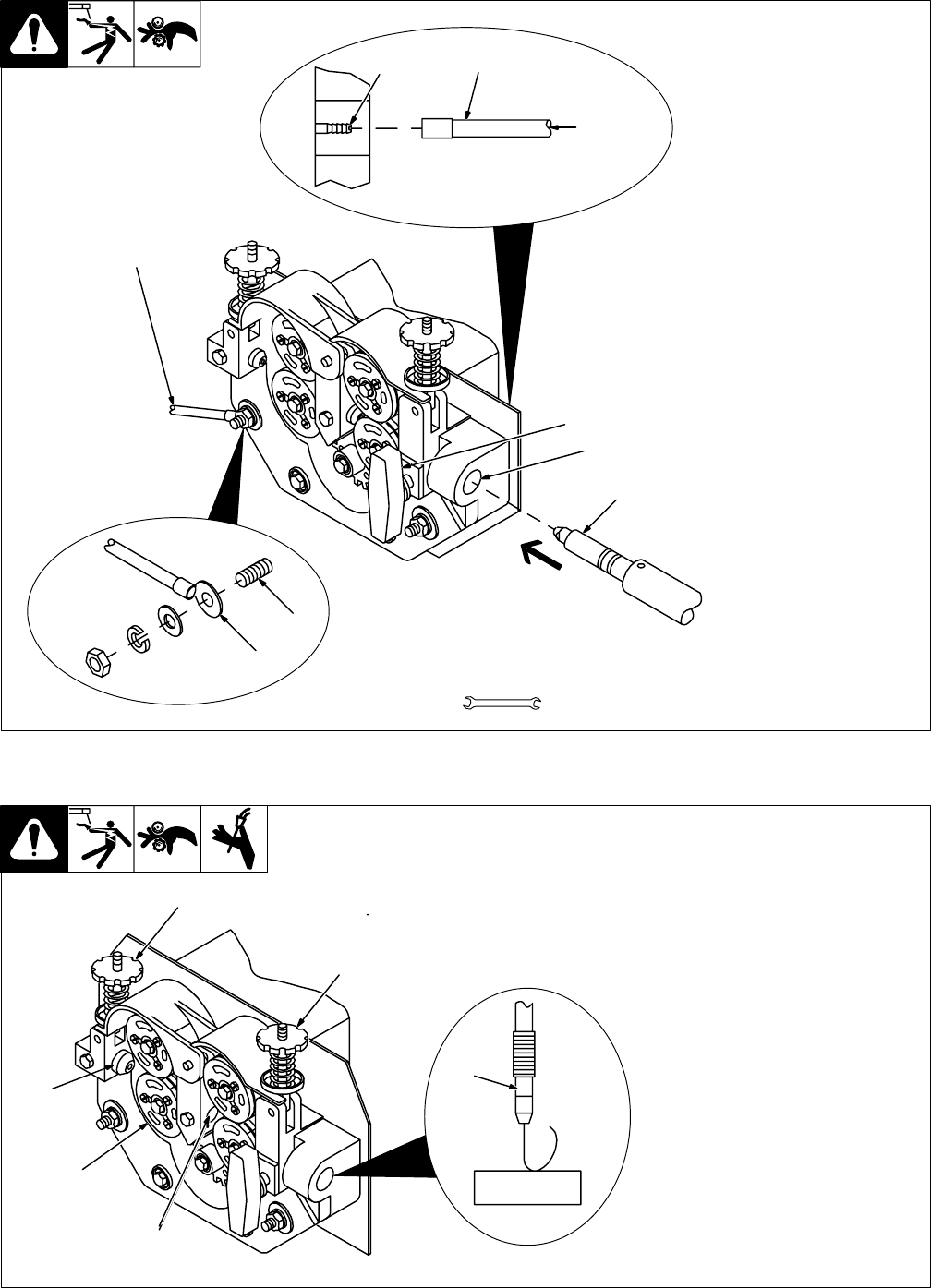

3-3. Threading And Feeding Welding Wire

ST-045 282-C / Ref. ST-156 798

Loosen wire from wire spool, cut off

bent wire, and pull 6 in (150 mm) of

wire off spool.

1 Wire Inlet Guide

2 Drive Roll

3 Intermediate Wire Guide

4 Gun

Thread wire through inlet guide,

along drive rolls, through intermedi-

ate guide and drive rolls, into outlet

cable, and out of the gun. Be sure

wire is in correct groove.

5 Pressure Adjustment Knob

And Arm

Close pressure roll assembly.

Check drive roll pressure by feed-

ing wire against a wood board or

concrete surface; wire should feed

steadily without slipping.

If pressure adjustment is neces-

sary, tighten pressure knobs.

1

WOOD

2

3

4

5

5