OM-228 956 Page 31

7-2. Diagnostics (Continued)

RMD DONE

• The RMD done message indicates the

RMD demo is completed. Pressing

Jog/Purge button will change the screen to

CYCL PWR on the display. Turn unit power

off and back on again.

OVER AVER

• The over average error indicates that

current is outside the average range for the

set program parameters. Check and correct

program parameters. Press Jog/Purge

button to clear error.

UNIT COMM

• The unit communication error indicates

the data bus on the PCM board is not

functioning properly. Press Jog/Purge

button to clear error.

REL TRIG

• The release trigger error indicates the

user held the gun trigger after a timed weld

was completed causing the contactor to

remain on. Press Jog/Purge button to clear

error.

TRIG STUK

• The trigger stuck error indicates the user

held the gun trigger during power up. Press

Jog/Purge button to clear error.

ERR UNKN

• The unknown error indicates a

malfunction in the system somewhere.

Press Jog/Purge button to clear error.

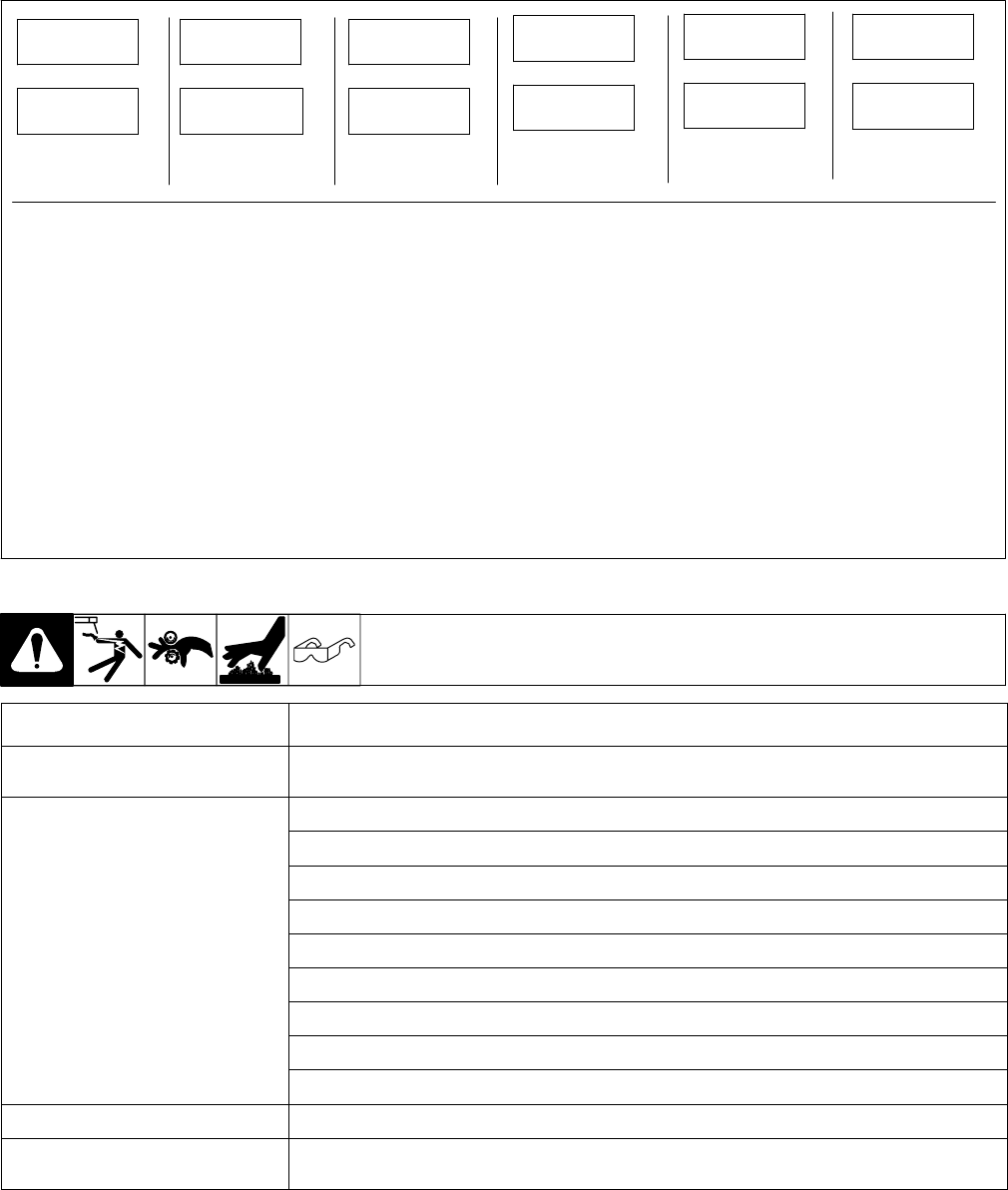

UNIT

COMM

ERR

UNKN

Indicates a CRC

PCM bus error.

Indicates an

unknown error.

RMD

DONE

OVER

AVER

Indicates RMD

demo is done.

Indicates an over

average current error.

REL

TRIG

Indicates a contactor

on error.

TRIG

STUK

Indicates a trigger

closed error.

7-3. Troubleshooting

Y Disconnect power before troubleshooting

Trouble Remedy

Wire feeds, shielding gas flows, but

electrode wire is not energized.

Check and secure weld cable connections (see Section 4-2).

Electrode wire feeding stops or feeds

erratically during welding

Check gun trigger connection. See gun Owner’s Manual.

erratically during welding.

Check gun trigger. See gun Owner’s Manual.

Readjust hub tension and drive roll pressure (see Section 4-9).

Change to correct size drive roll (see Table 9-1).

Clean or replace dirty or worn drive roll.

Incorrect size or worn wire guides.

Replace contact tip or liner. See gun Owner’s Manual.

Remove weld spatter or foreign matter from around nozzle opening.

Have Factory Authorized Service Agency check drive motor or motor control board PC1.

Motor runs slowly. Check for correct input voltage.

Wire feeder power is on, displays light

up, but unit is inoperative.

Check welding gun trigger leads for continuity, and repair leads or replace gun.