. A complete Parts List is available at www.MillerWelds.com

OM-222 Page 24

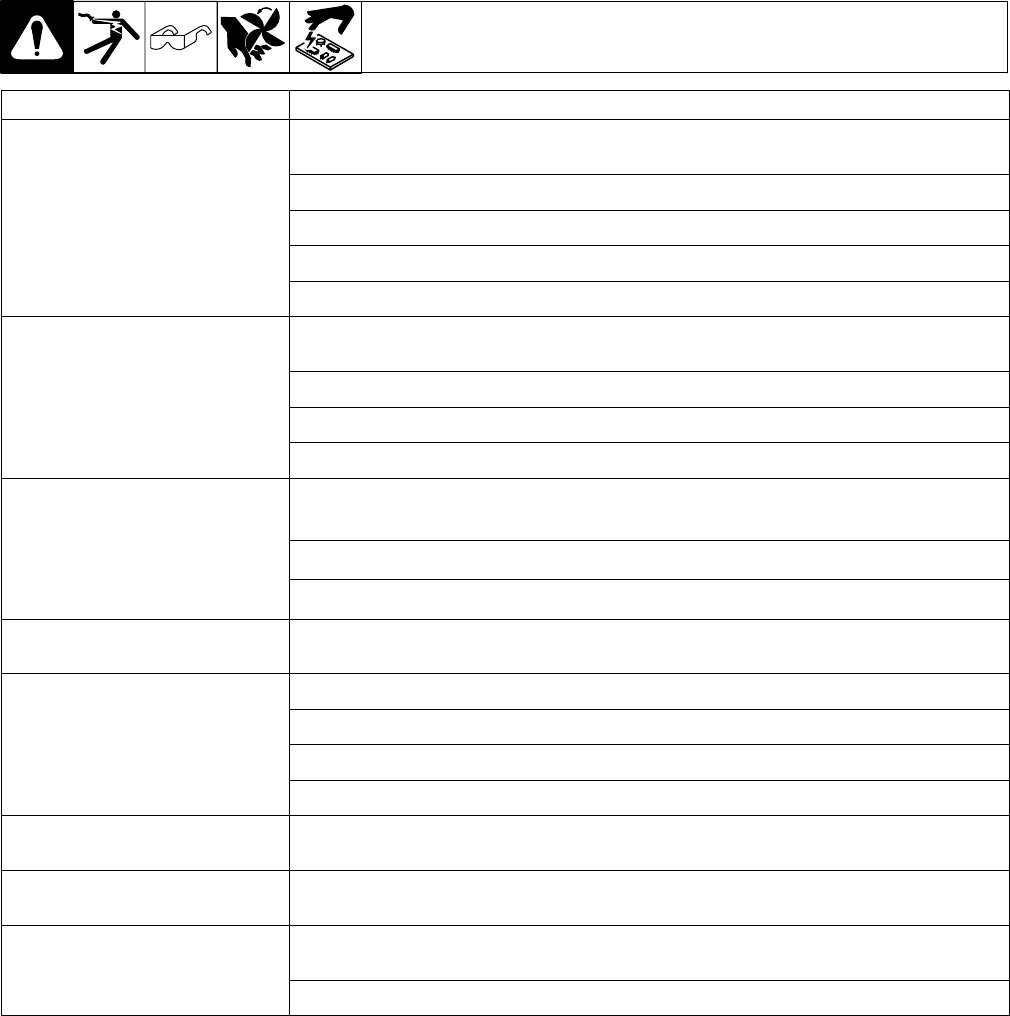

6-3. Troubleshooting

Trouble Remedy

No weld output; unit completely inop-

erative.

Place line disconnect switch in On position (see Section 4-15).

Check fuse F1, and replace if necessary (see Section 6-2).

Check and replace line fuse(s), if necessary, or reset circuit breaker (see Section 4-15).

Check for proper input power connections (see Section 4-15).

Check for proper jumper link position (see Section 4-14).

No weld output; Power switch pilot light

on; fan on.

If using remote control, place Output (Contactor) switch in Remote 14 position, and connect remote

control (see Section 4-12). If remote is not being used, place switch in On position.

Check, repair, or replace remote control.

Unit overheated. Allow unit to cool with fan On (see Section 4-2).

Have Factory Authorized Service Agent check control board PC1.

No weld output; Power switch pilot light

on; fan off.

Check for proper input power connections (see Section 4-15).

Check and replace line fuse(s), if necessary, or reset circuit breaker (see Section 4-15).

Have Factory Authorized Service Agent check SCR’s.

Unit provides only maximum or mini-

mum weld output.

Have Factory Authorized Service Agent check control board PC1 and hall device HD1.

Erratic or improper weld output. Use proper size and type of weld cable (see Section 4-9).

Clean and tighten all weld connections.

Check position of Polarity selector switch (see Section 5-1).

Have Factory Authorized Service Agent check control board PC1 and hall device HD1.

No 115 volts ac output at duplex recep-

tacle, Remote 14 receptacle.

Reset supplementary protector CB1 (see Section 4-7).

No 24 volts ac output at Remote 14 re-

ceptacle.

Reset supplementary protector CB2 (see Section 4-7).

Fan not operating. NOTE: fan only

runs when cooling is necessary.

Check for and remove anything blocking fan movement.

Have Factory Authorized Service Agent check fan motor.