OM-1572 Page 7

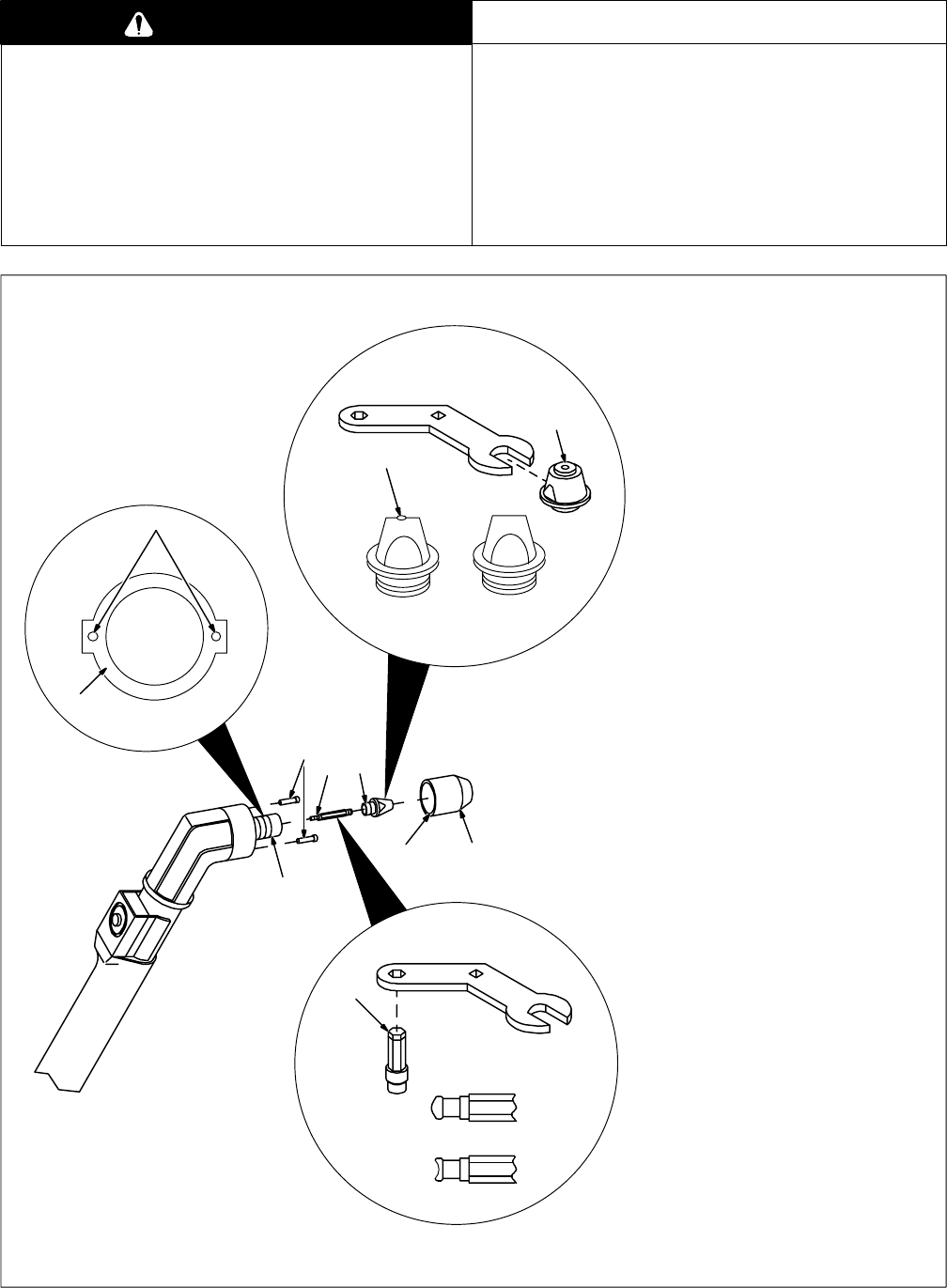

5-2. Checking Detector Pins And Checking/Replacing Shield Cup, Tip, And Electrode

CAUTION

OVERTIGHTENING will strip threads.

• Do not overtighten electrode, tip, and shield cup during assembly.

• Do not cross-thread parts causing stripping.

• Use care during torch assembly and parts replacement.

TIP AND ELECTRODE WEAR BEYOND

RECOMMENDED VALUES or OPERATION

WITHOUT TIP OR ELECTRODE can damage

torch.

• Inspect shield cup, tip, and electrode before cutting or whenever

cutting speed has been significantly reduced.

• Do not operate torch without a tip or electrode in place.

• Be sure to use genuine replacement parts.

• A good practice is to replace both the tip and electrode at the same

time.

Ref. ST-800 225 / Ref. S-0093

Turn Off power source, and discon-

nect input power.

1 Shield Cup

2 Contact Surface

3 Detector Pins

Unscrew shield cup, and wipe con-

tact surfaces with a soft cloth. Con-

tact surfaces must be clean so

spring-loaded detector pins de-

press when shield cup is installed.

Check shield cup for cracks, and

replace if necessary.

Check detector pins to make sure

they move freely. If necessary, use

electrical contact cleaner to loosen

them.

4Tip

5 Opening

Remove tip using supplied wrench.

Check tip, and replace if opening is

deformed or 50% oversize.

6 Electrode

Check electrode. If more than 0.039

in (1 mm) of the end is eroded, re-

move electrode using supplied

wrench, and replace.

Carefully reassemble in reverse or-

der.

Thread Sizes:

A M8 x .75

B M3 x .5

C M12 x 1

New

Worn

New Worn

4

5

6

2

3

21

C

B

3

A