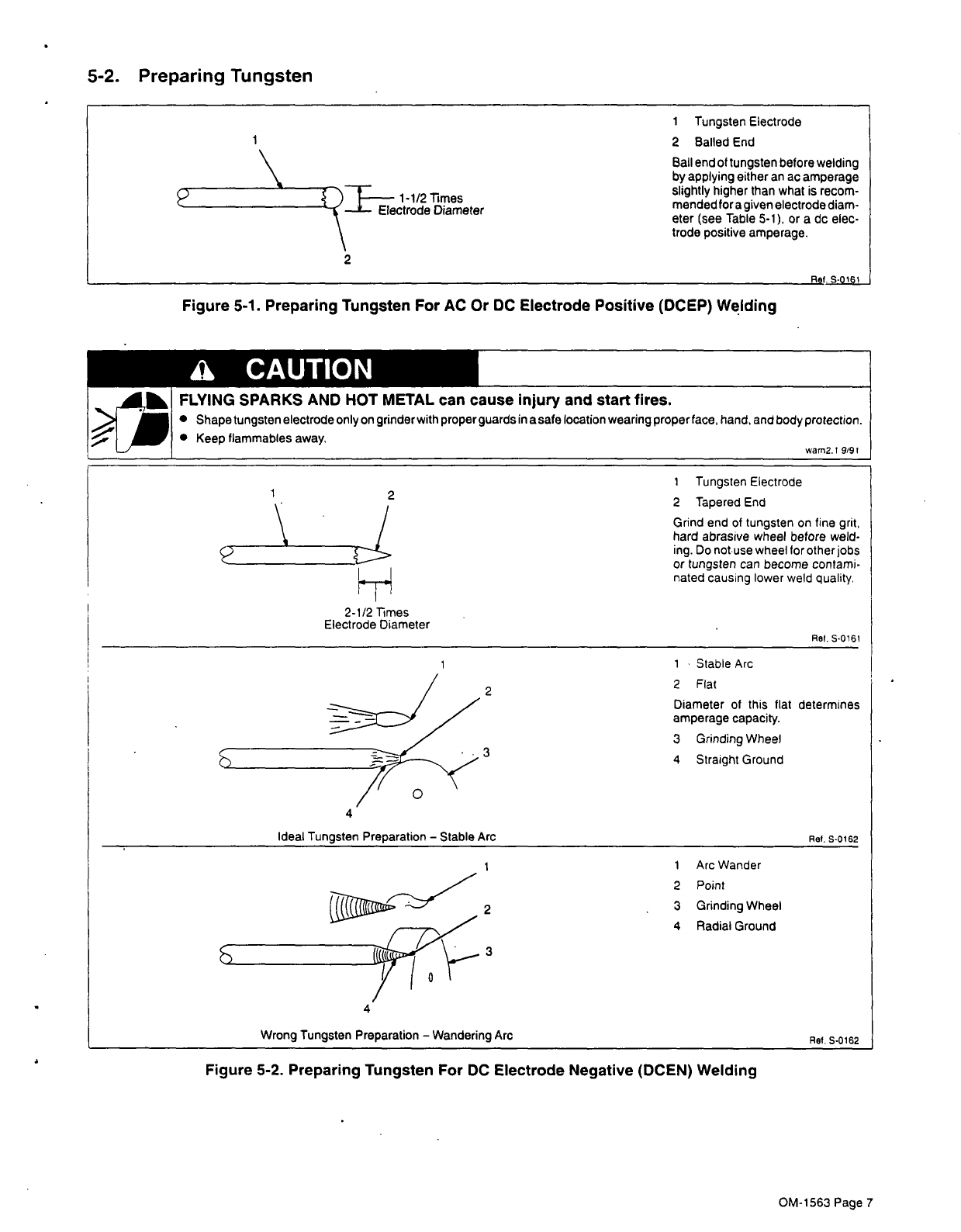

5-2.

Preparing

Tungsten

Figure

5-1.

Preparing

Tungsten

For

AC

Or

DC

Electrode

Positive

(DCEP)

Welding

H

2-1/2

Times

Electrode

Diameter

1

Tungsten

Electrode

2

Tapered

End

Grind

end

of

tungsten

on

fine

grit,

hard

abrasive

wheel

before

weld.

ing.

Do

notuse

wheel

for

other

jobs

or

tungsten

can

become

contami

nated

causing

lower

weld

quaIity~

Ret

S0161

Wrong

Tungsten

Preparation

Wandering

Arc

Ref.

S-0162

1

Tungsten

Electrode

2

Balled

End

Ball

end

of

tungsten

before

welding

by

applying

either

an

ac

amperage

Electrode

Diameter

mended

for

a

given

electrode

diam

P

1iI~IIE

1-1/2

Times

slightly

higher

than

what

is

recom

eter

(see

Table

5.1),

or

a

dc

elec

trode

positive

amperage.

2

Ref.

S-0161

a

CAUTION

FLYING

SPARKS

AND

HOT

METAL

can

cause

injury

and

start

fires.

Shape

tungsten

electrode

only

on

grinder

with

proper

guards

in

a

sate

location

wearing

proper

face.

hand,

arid

body

protection.

Keep

flammables

away.

wam2.1

9/91

2

1

1

Stable

Arc

V

2

FIat

Diameter

of

this

flat

amperage

capacity.

3

Grinding

Wheel

4

Straight

Ground

determines

4

Ideal

Tungsten

P

reparation

Stable

Arc

Ref.

S0162

2

3

4

1

Arc

Wander

2

Point

3

Grinding

Wheel

4

Radial

Ground

Figure

5-2.

Preparing

Tungsten

For

DC

Electrode

Negative

(DCEN)

Welding

OM-1563

Page

7