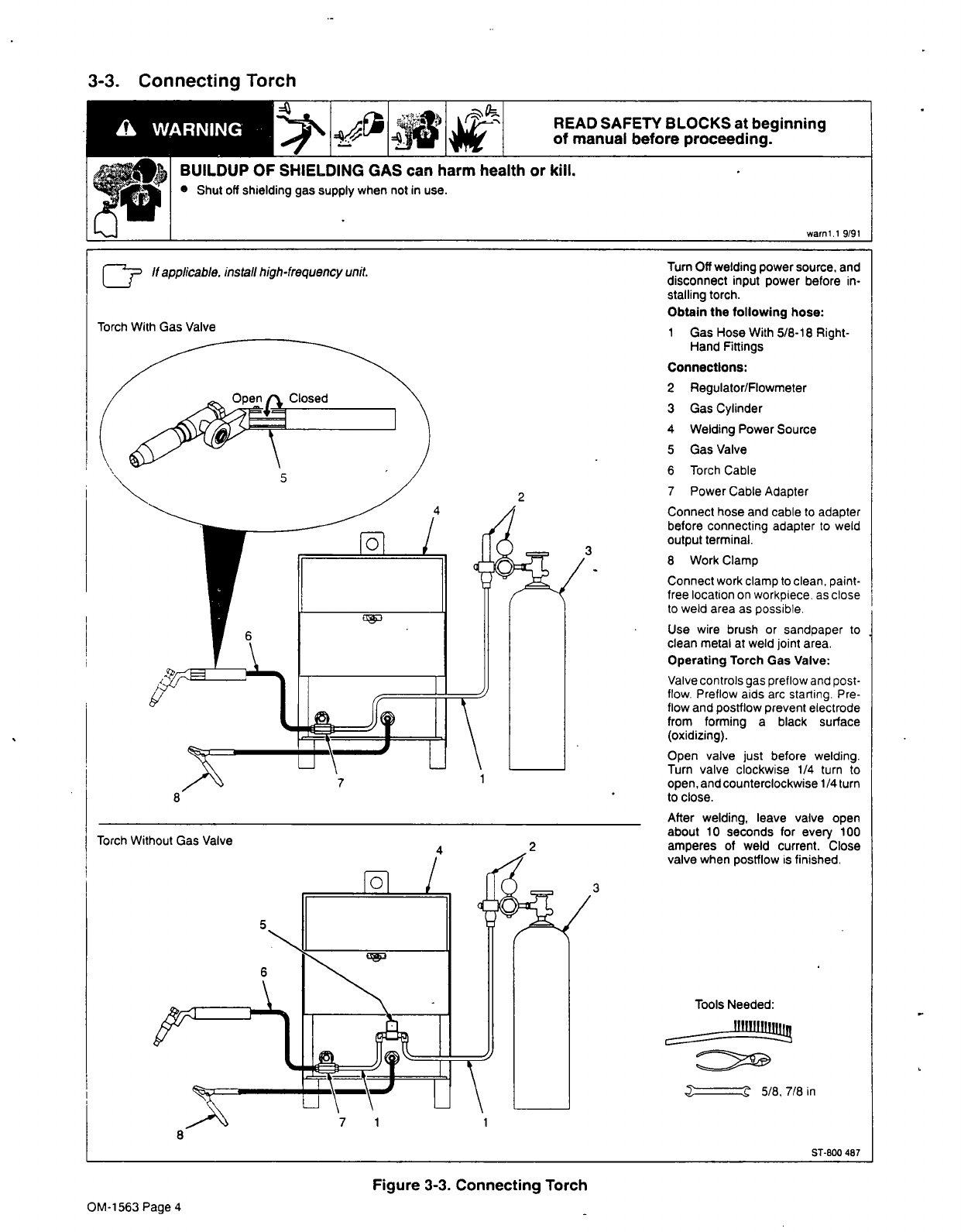

3-3.

Connecting

Torch

~

~

~

READ

SAFETY

BLOCKS

at

beginning

4jj~1

~

of

manual

before

proceeding.

BUILDUP

OF

SHIELDING

GAS

can

harm

health

or

kill.

0

Shut

off

shielding

gas

supply

when

not

in

use.

warnl.1

9/91

Turn

Off

welding

power

source,

and

If

applicable.

install

high-frequency

unit,

disconnect

input

power

before

in

stalling

torch.

Obtain

the

following

hose:

Torch

With

Gas

Valve

1

Gas

Hose

With

5/8-18

Right-

Hand

Fittings

Connections:

2

Regulator/Flowmeter

3

Gas

Cylinder

4

Welding

Power

Source

5

Gas

Valve

6

Torch

Cable

7

Power

Cable

Adapter

Connect

hose

and

cable

to

adapter

before

connecting

adapter

to

weld

output

terminal.

8

Work

Clamp

Connect

work

clamp

to

clean,

paint-

free

location

on

workpiece.

as

close

to

weld

area

as

possible.

Use

wire

brush

or

sandpaper

to

clean

metal

at

weld

joint

area.

Operating

Torch

Gas

Valve:

Valve

controls

gas

preflow

and

post

flow.

Preflow

aids

arc

starting.

Pre

low

and

postflow

prevent

electrode

from

forming

a

black

surface

(oxidizing).

Open

valve

just

before

welding.

Turn

valve

clockwise

1/4

turn

to

open,

and

counterclockwise

1/4

turn

to

close.

________

After

welding,

leave

valve

open

about

10

seconds

for

every

100

amperes

of

weld

current.

Close

valve

when

postflow

is

finished.

3

Tools

Needed:

~

5/8,

7/8

in

sT-BOO

487

Torch

Without

Gas

Valve

8

Figure

3-3.

Connecting

Torch

OM-1563

Page

4