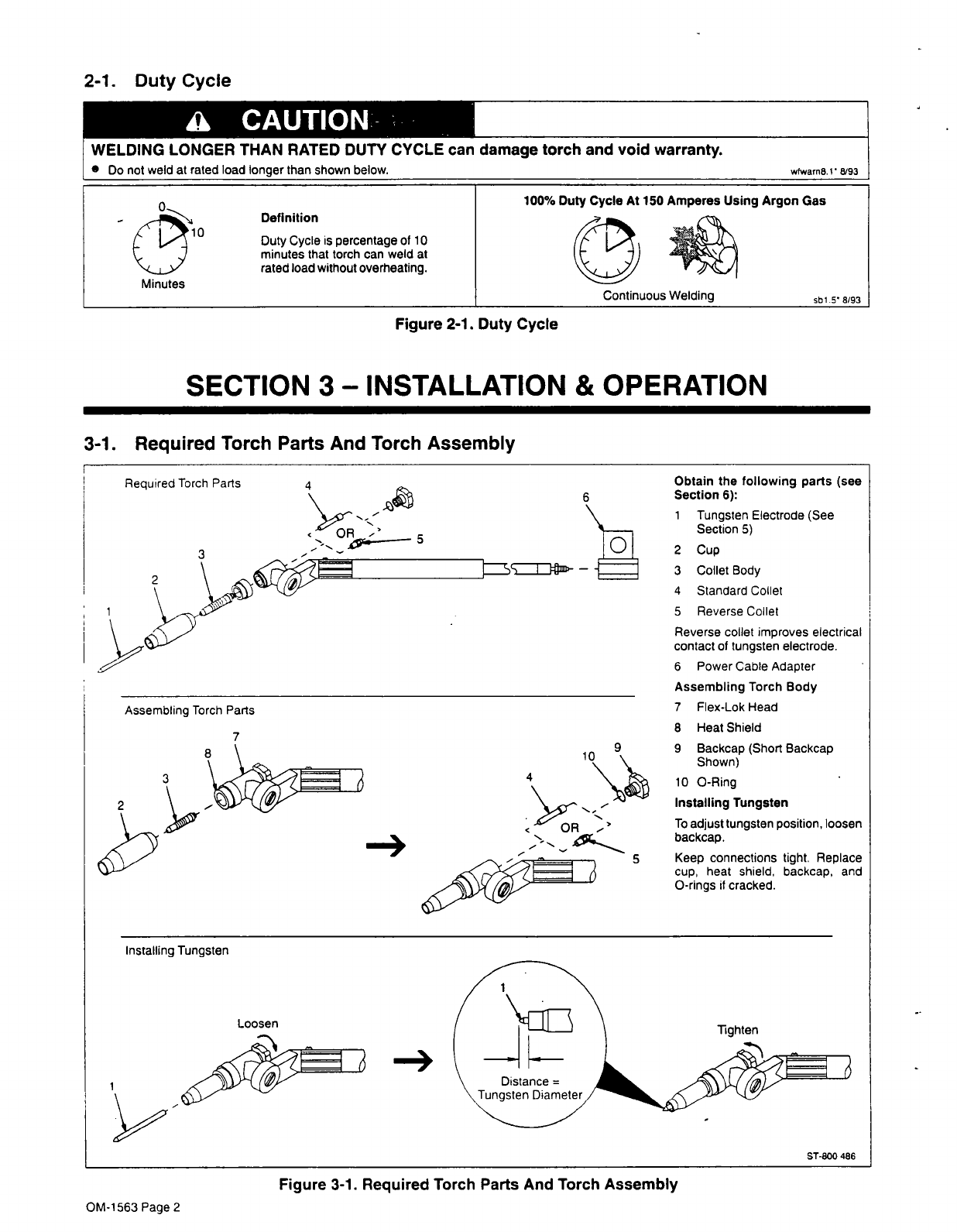

2-1.

Duty

Cycle

Obtain

the

following

parts

(see

Section

6):

1

Tungsten

Electrode

(See

Section

5)

2

Cup

3

Collet

Body

4

Standard

Collet

5

Reverse

Collet

Reverse

collet

improves

electrical

contact

of

tungsten

electrode.

6

Power

Cable

Adapter

Assembling

Torch

Body

7

Flex-Lok

Head

8

Heat

Shield

9

Backcap

(Short

Backcap

Shown)

10

0-Ring

Installing

Tungsten

To

adjust

tungsten

position,

loosen

backcap.

5

Keep

connections

tight.

Replace

cup,

heat

shield,

backcap,

and

0-rings

f

cracked.

Installing

Tungsten

-~

ST-800

486

Figure

3-1.

Required

Torch

Parts

And

Torch

Assembly

a

CAUTIONS

WELDING

LONGER

THAN

RATED

DUTY

CYCLE

can

damage

torch

and

void

warranty.

Do

not

weld

at

rated

load

longer

than

shown

below.

wfwarn8.1~

8/93

0

Definition

Duty

Cycle

is

percentage

of

10

-

10

rated

load

without

overheating.

minutes

that

torch

can

weld

at

Minutes

100%

D

uty

Cycle

At

150

Amperes

Using

Argo

Continuous

Welding

n

Gas

sb1.5~

8/93

Figure

2-1.

Duty

Cycle

SECTION

3-

INSTALLATION

&

OPERATION

3-1.

Required

Torch

Parts

And

Torch

Assembly

Required

Torch

Parts

4

3

Assembling

Torch

Parts

7

3

-~

10

OR

~-

Loosen

Tighten

OM-1563

Page

2