a

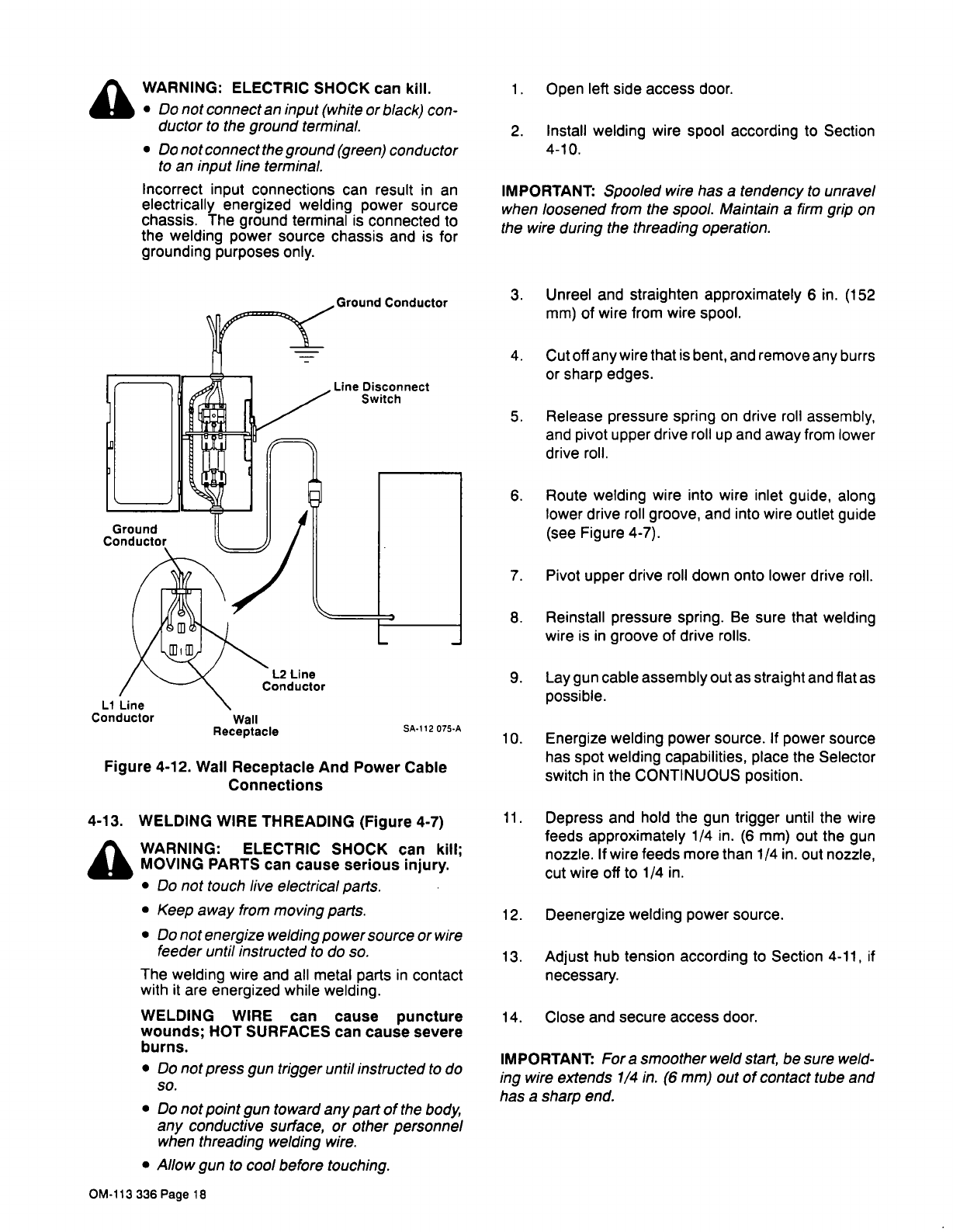

WARNING:

ELECTRIC

SHOCK

can

kill.

Do

not

connect

an

input

(white

or

black)

con

ductor

to

the

ground

term

mal.

Do

not

connect

the

ground

(green)

conductor

to

an

input

line

terminal.

Incorrect

input

connections

can

result

in

an

electrically

energized

welding

power

source

chassis.

The

ground

terminal

is

connected

to

the

welding

power

source

chassis

and

is

for

grounding

purposes

only.

Wall

Receptacle

Figure

4-12.

Wall

Receptacle

And

Power

Cable

Connections

4-13.

WELDING

WIRE

THREADING

(Figure

4-7)

a

WARNING:

ELECTRIC

SHOCK

can

kill;

MOVING

PARTS

can

cause

serious

injury.

Do

not

touch

live

electrical

parts.

Keep

away

from

moving

parts.

Do

not

energize

welding

power

source

or

wire

feeder

until

instructed

to

do

so.

The

welding

wire

and

all

metal

parts

in

contact

with

it

are

energized

while

welding.

WELDING

WIRE

can

cause

puncture

wounds;

HOT

SURFACES

can

cause

severe

burns.

Do

not

press

gun

trigger

until

instructed

to

do

so.

Do

not

point

gun

toward

any

part

of

the

body,

any

conductive

surface,

or

other

personnel

when

threading

welding

wire.

Allow

gun

to

cool

before

touching.

1.

Open

left

side

access

door.

2.

Install

welding

wire

spool

according

to

Section

4-10.

IMPORTANT:

Spooled

wire

has

a

tendency

to

unravel

when

loosened

from

the

spool.

Maintain

a

firm

grip

on

the

wire

during

the

threading

operation.

3.

Unreel

and

straighten

approximately

6

in.

(152

mm)

of

wire

from

wire

spool.

4.

Cutoff

any

wire

that

is

bent,

and

remove

any

burrs

or

sharp edges.

5.

Release

pressure

spring

on

drive

roll

assembly,

and

pivot

upper

drive

roll

up

and

away

from

lower

drive

roll.

6.

Route

welding

wire

into

wire

inlet

guide,

along

lower

drive

roll

groove,

and

into

wire

outlet

guide

(see

Figure

4-7).

7.

Pivot

upper

drive

roll

down

onto

lower

drive

roll.

8.

Reinstall

pressure

spring.

Be

sure

that

welding

wire

is

in

groove

of

drive

rolls.

9.

Lay

gun

cable

assembly

out

as

straight

and

flat

as

possible.

10.

Energize

welding

power

source.

If

power

source

has

spot

welding

capabilities,

place

the

Selector

switch

in

the

CONTINUOUS

position.

11.

Depress

and

hold

the

gun

trigger

until

the

wire

feeds

approximately

1/4

in.

(6

mm)

out

the

gun

nozzle.

If

wire

feeds

more

than

1/4

in.

out

nozzle,

cut

wire

off

to

1/4

in.

12.

Deenergize

welding

power

source.

13.

Adjust

hub

tension

according

to

Section

4-11,

if

necessary.

14.

Close

and

secure

access

door.

IMPORTANT:

For

a

smoother

weld

start,

be

sure

weld

ing

wire

extends

1/4

in.

(6

mm)

out

of

contact

tube

and

has

a

sharp

end.

Ground

Conductor

Line

Disconnect

Switch

Li

Line

Conductor

L2

Line

Conductor

SA-112

075-A

OM-113

336

Page

18