OM-1500-9 Page 24

OPT2

• If the Setup push button is pressed, the unit

allows OPT2 to be disabled or enabled.

The upper display shows “OPT2”. Lower dis-

play shows “On” or “Off”. The Adjust Control

is used to select either “On” or “Off”.

“OPT2” is a second input that may be used

with an external device, such as a gas flow

switch, to end the weld sequence. The gas

flow switch may be used to stop the weld se-

quence if shielding gas flow to the gun is inter-

rupted. A closed set of contacts between pins

1 and 2 of RC24 on Interface Board (PC20)

will allow feeder to operate normally. Opening

the contacts will stop the weld sequence and

display “ERR” in the upper display and

“OPT2” in the lower display.

Display Hold

Display hold indicated by ”DISP” in the upper

display is set to “OFF” or “HOLD” in the lower

display. When ”HOLD” is selected, the unit will

hold the last weld information for 5 seconds

following weld termination. If any front panel

push button is pressed, or if the Adjust control

is activated, the display hold feature is termi-

nated.

Software Revision Level

• If the Setup push button is pressed, the unit

displays the software version being used by

the interface PCB (PC20).

• When the Setup button is pressed again, the

menu repeats.

Code

Upon leaving the auxiliary menu, the user is

asked if a password code indicated by

“CODE” in the top display should be activated.

By default the code is off, indicated by “OFF”

in the lower display. The user may enter a nu-

merical password between 0 and 999 by turn-

ing the Adjust control. When the user re−en-

ters the auxiliary menu, the password code

must be selected to gain access to the auxilia-

ry menu. A failed attempt return the user to the

weld screen and a counter is incremented. A

counter in the program display shows the

number of incorrect attempts. The user has

five attempts to enter the correct password

code before being locked out of the auxiliary

menu, indicated by “LOCK” in the lower dis-

play . The power may be cycled to continue

welding but the user will remained locked out

of the auxiliary menu. Pressing the Program,

Sequence, upper display, and Set−up push

buttons simultaneously, the counter can be re-

set in the weld screen. Resetting the counter

is indicated by “CODE” in the upper display

and “RSET” in the lower display. Pressing the

Program, Sequence, upper display, and Set−

up push buttons simultaneously again will al-

low the user to reset the unit to the factory de-

faults, indicated by “WIPE” in the upper dis-

play. Resetting the unit will also turn off the

password code feature.

6-10 Auxiliary Menus (Continued)

6-11. Jog/Purge

Pressing the Jog/Purge switch allows the op-

erator to jog wire without energizing the weld

power or gas valve circuit.

• The unit provides the ability to jog the wire

feeder by means of the gun trigger or the

Jog/Purge switch. If the welding arc does

not initiate in 3 seconds after the gun trigger

is activated, the unit will perform a jog opera-

tion for a maximum of two minutes. If the gun

trigger is still activated after two minutes, the

jog operation is terminated to prevent com-

plete despooling of the wire, in the case of

a damaged gun.

• The unit displays the “ERR TRIG“ message

to inform the operator that the trigger is acti-

vated.

• Jog speed can be adjusted by the Adjust

control when the unit is jogging wire. The

unit displays jog speed when the unit is be-

ing jogged.

• Jogging can also be accomplished by

pressing the Jog/Purge button.

• Pressing the Jog/Purge button also allows

the operator to purge gas lines before weld-

ing and to preset gas pressure at the

regulator.

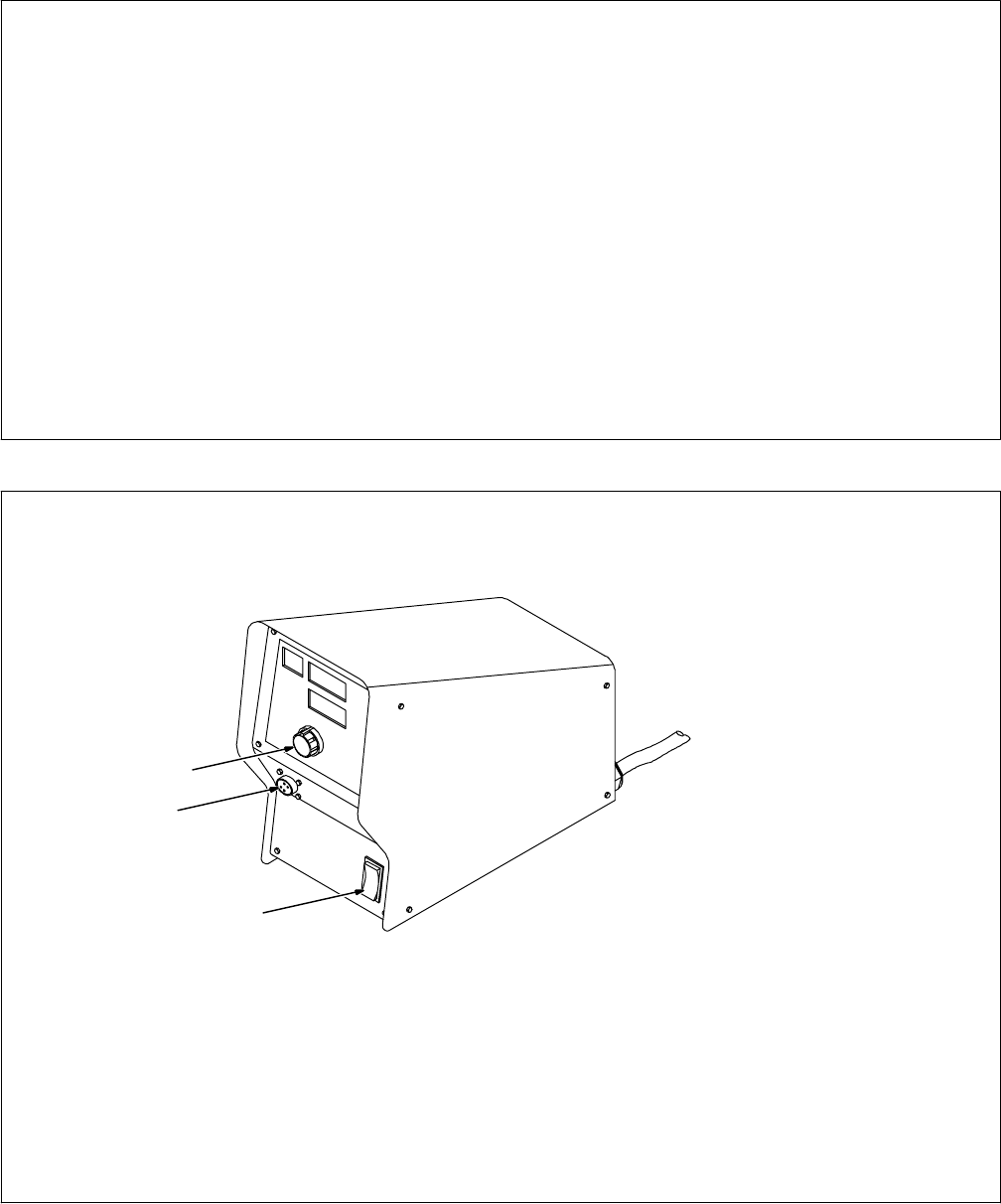

1

802 807

2

3

1 Jog/Purge Push Button

2 Adjust Control

3 Gun Trigger Receptacle