OM-2236 Page 21

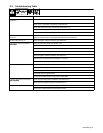

6-3. Troubleshooting Table

Trouble Remedy

No weld output; unit completely

inoperative.

Place line disconnect switch in On position (see Section 4-12).

Check fuse F1 and replace if necessary (see Section 6-2).

Check and replace line fuse(s) if necessary (see Section 4-12).

Check for proper input power connections (see Section 4-12).

Check for proper jumper link position (see Section 4-11).

No weld output, power switch light on,

but fan off.

Unit overheated, allow unit to cool (see Section 4-2). NOTE: When unit has cooled, fan starts and

weld output is present at the weld output terminals and/or at the electrode.

No weld output, but fan on. Clean and tighten all weld connections (see Section 6-1).

Unit provides only low or minimum

weld output.

Check for proper line voltage (see Section 4-12).

weld output.

Check for proper input power connections (see Section 4-12).

Check for proper jumper link position (see Section 4-12).

Check for open line fuse(s), and replace if necessary (see Section 4-12).

Clean and tighten all weld connections (see Section 6-1).

Select correct size weld cables (see Sections 4-7 and 4-8).

Have factory authorized Service Agent check rectifier SR1.

Erratic or improper weld output. Check for proper input power connections (see Section 4-12).

Use proper size and type weld cables (see Sections 4-7 and 4-8).

Clean and tighten all weld connections (see Section 6-1).

Use proper size and type electrodes.

Have factory authorized Service Agent check rectifier SR1.

Excessive line current or line fuse(s)

open repeatedly.

Check for proper input power connections (see Section 4-12).

open repeatedly.

Check for proper jumper link position (see Section 4-11).

Fan not operating and/or over heating. Check for and remove anything blocking fan movement.

Have factory authorized Service Agent check fan motor.