OM-353 Page 21

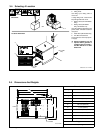

4-4. Crater Time Controls

1 Crater Time Control

Use control to reduce current over a

set period of time (0–15 seconds) at

the end of the weld cycle when NOT

using a remote current control.

2 Crater Time Switch

ON – provides crater time.

OFF – provides no crater time.

Place switch in the OFF position for

Shielded Metal Arc Welding

(SMAW).

Application:

Crater Time should be used while

GTAW welding materials that are

crack sensitive, and/or the operator

wants to eliminate the crater at the

end of the weld.

Note: This applies if the operator is

using an on/off only type control to

start and stop the welding process.

2

1

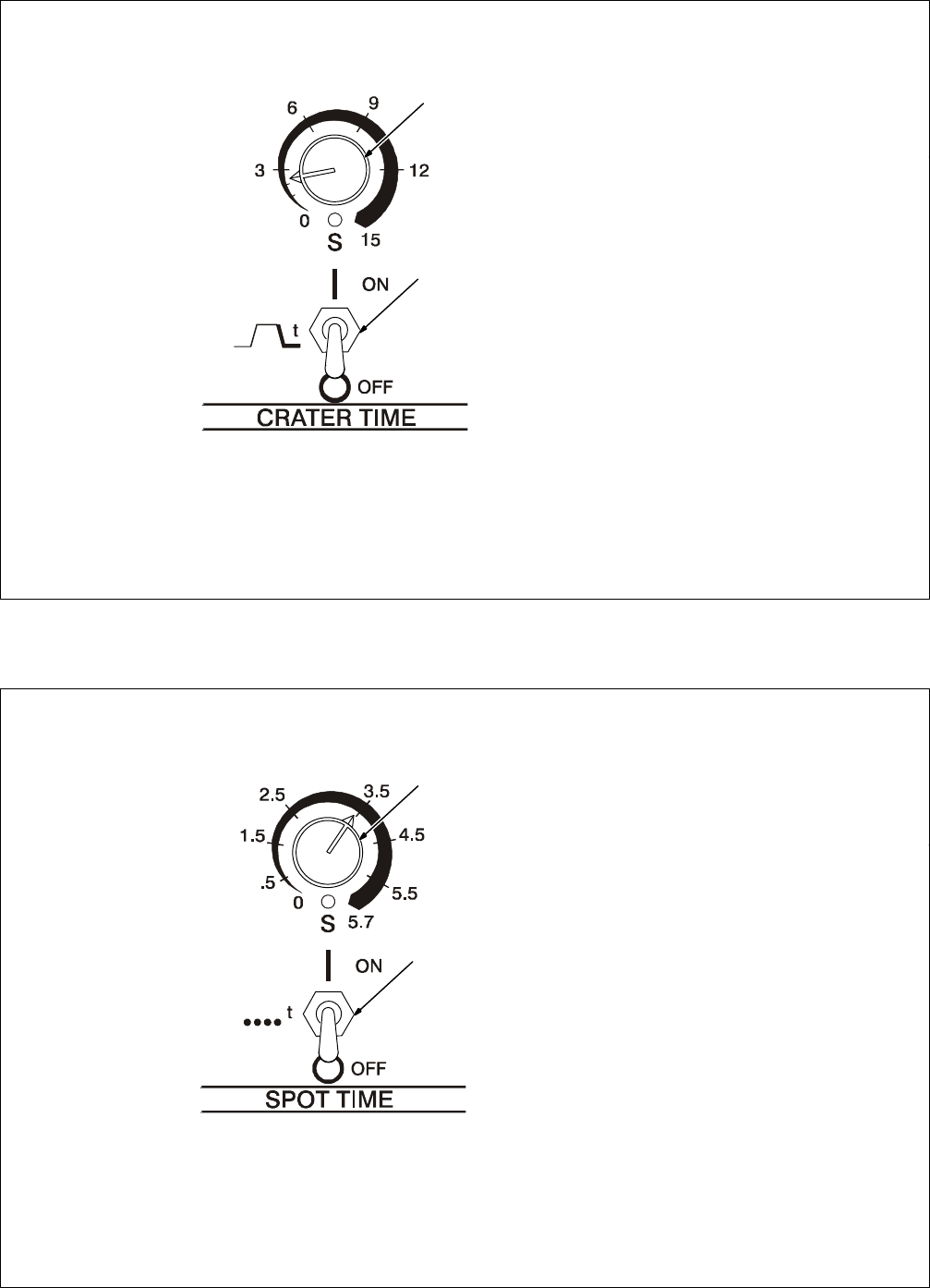

4-5. Spot Time Controls

1 Spot Time Switch

Place switch in the ON position to

turn on spot weld circuitry.

The (GTAW) TIG Spot process is

generally used with a direct current

electrode negative (DCEN) set-up.

Place switch in the OFF position to

turn off spot weld circuitry. Put

switch in the OFF position while do-

ing Shielded Metal Arc Welding

(SMAW).

2 Spot Time Control

Use control to set time (0–5.7 sec-

onds) for Gas Tungsten Arc

(GTAW) spot welds. Spot time be-

gins at arc initiation. If the arc is bro-

ken during the spot time cycle, the

timer stops but does not reset.

When the spot time has ended,

weld output stops. Postflow starts

when the remote contactor is

opened. The spot timer resets after

the contactor opens.

Application:

TIG spot welding is used for joining

thinner materials that are in close

contact, with the fusion method. A

good example would be joining coil

ends.

1

2