8 9

WARNING

TOOL ASSEMBLY

To reduce the risk of injury,

always unplug tool before attaching

or removing accessories or making

adjustments. Use only specifi cally

recommended accessories. Others

may be hazardous.

Removing and Replacing Quik-Lok

®

Cords

MILWAUKEE's exclusive Quik-Lok

®

Cords

provide instant fi eld replacement or sub-

stitution.

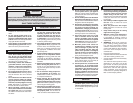

Fig. 1

1. To remove the Quik-Lok

®

Cord, turn the

cord nut 1/4 turn to the left and pull it

out.

2. To replace the Quik-Lok

®

Cord, align

the connector keyways and push the

connector in as far as it will go. Turn the

cord nut 1/4 turn to the right to lock.

Installing Side Handle

Ring Clamp, Extension, and Side Handle

for Right Angle Drive Unit

For D-handle drill with Right Angle Drive

Unit:

A ring clamp, extension, and side handle

are supplied with the Right Angle Drive Unit.

When using a right angle drive unit, attach

the side handle to the ring clamp. Do not use

the extension when using the ring clamp. The

ring clamp with attached side handle clamps

onto the right angle drive unit and can swivel

360° and locked tight in any position.

For D-handle drill without Right Angle Drive

Unit:

When using the D-handle drill without the

right angle drive unit, remove the ring clamp

with attached side handle, then remove the

side handle from the ring clamp. Attach

the side handle to the extension. The side

handle can be installed on either side of the

tool for right or left handed use. To install

the extension with attached side handle,

thread it into the socket on the desired side

of the tool (for right or left-handed use) and

tighten securely.

NOTE: If you have an extra ring clamp

with attached side handle and extension

with attached side handle, do not use the

extension with attached side handle when

using the right angle drive unit. Remove it

from the tool.

WARNING

To reduce the risk of injury, always

use a side handle when using this

tool. This tool operates with high

torque. Always brace or hold the

tool securely.

WARNING

When using the D-handle drill with-

out the right angle drive unit, do not

clamp the ring clamp with attached

side handle to the front of the gear

case; use the side handle instead.

Do not use the extension when us-

ing the ring clamp.

MILWAUKEE D-Handle Drills are supplied

with a side handle that can be installed on

either side of the tool for right or left handed

use. To install the side handle, attach the

side handle to the extension. Thread it into

the socket on the desired side of the tool

and tighten it securely. Because of the high

torque of this drill, the side handle must al-

ways be used when operating the drill.

Be sure that the shank of the bit and the

chuck jaws are clean. Dirt particles may

cause the bit to line up improperly. Do not

use bits larger than the maximum recom-

mended capacity of the drill because gear

damage or motor overloading may result.

For best performance, be sure that the bits

are properly sharpened before use.

1. Unplug the tool.

2. Open the chuck jaws wide enough to

insert a bit. Allow the bit to strike the

bottom of the chuck. Center the bit in

the chuck jaws and tighten the jaws by

hand to align the bit.

3. Place the chuck key into each of the

three holes in the chuck, turning it clock-

wise to tighten the chuck securely.

NOTE: Never use a wrench or means

other than a chuck key to tighten or

loosen the chuck.

4. To remove the bit, insert the chuck key

into one of the holes in the chuck and

turn it counterclockwise.

Removing the Chuck from the Drill

1. To remove the left-hand screw inside the

chuck, unplug the tool and open the chuck

jaws. Insert a T-handle hex key into the

screw inside the chuck. Turn the T-handle

hex key and remove the screw. Save the

screw for installing your new chuck.

2. To remove chuck; tighten a large hex

key into the chuck. Place the chuck on a

workbench as shown. Strike the hex key

with a soft-headed mallet to loosen the

chuck. Remove the chuck by hand.

Attaching Right Angle Drive to Drill

1. Remove the chuck from the drill (see

“Removing the Chuck From the Drill”).

Slip the double hex coupling over the

hex on the drill spindle.

Loosen the clamping screws on the

clamping sleeve and slip the sleeve onto

the drill collar.

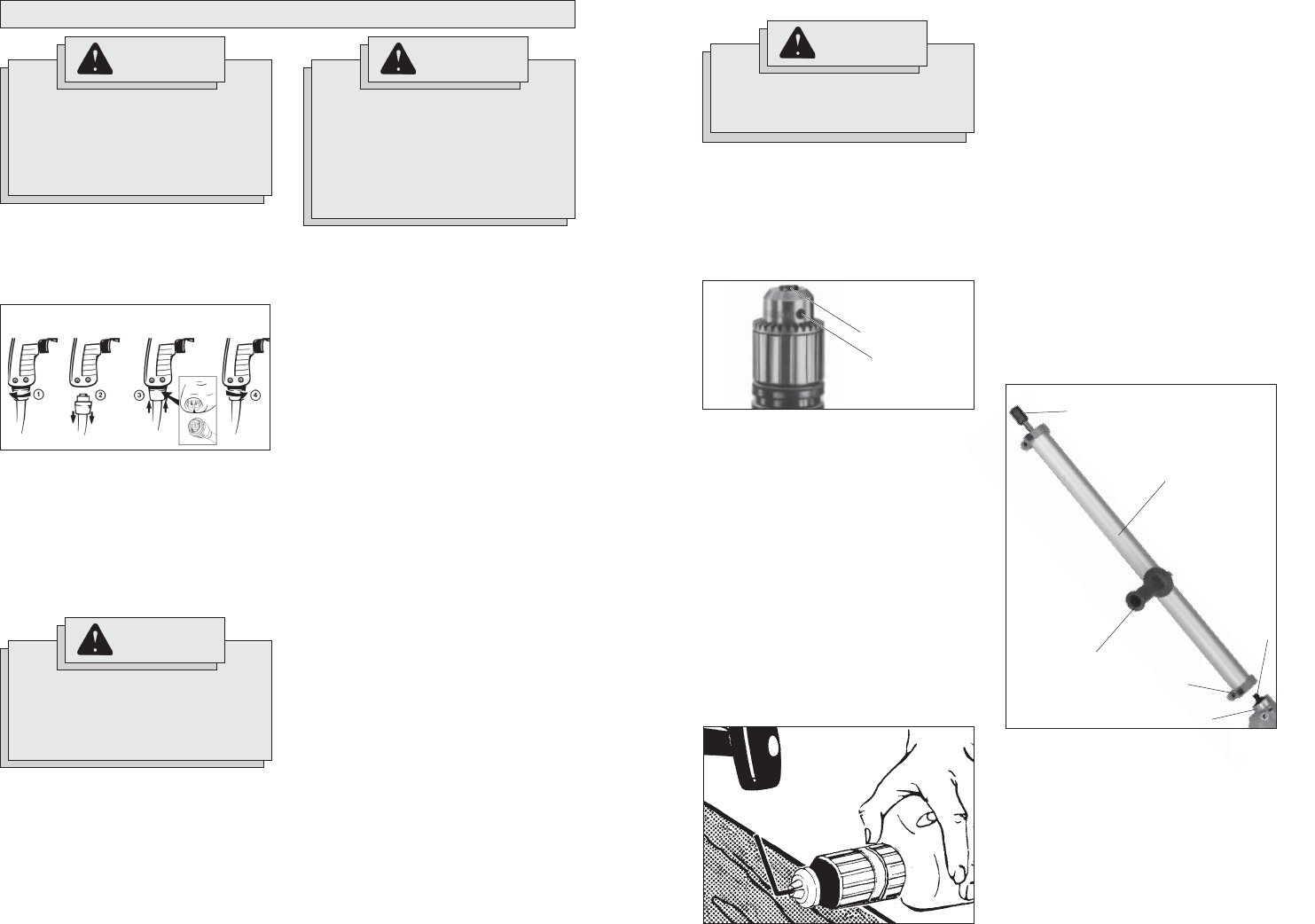

Fig. 3

Chuck jaws

Fig. 2

Chuck key hole

Installing Bits into Keyed Chucks

WARNING

To prevent personal injury, always

remove the chuck key from the

chuck after each use.

Installing 30"Extension Tube

Fig. 4

Auxiliary side

handle

30" Extension

tube

Clamp

Collar

Hex

drive

Drive shaft

The 30" extension tube MUST be used when

attaching the 33° Angle Drive. The extension

tube can optionally be used with the Right

Angle Drive.

1. Remove the chuck from the drill (see

“Removing the Chuck From the Drill”).

2. Slide extension tube over drill collar and

tighten clamp securely.

3. Slide auxiliary side handle onto 30"

extension tube and secure.

4. Insert drive shaft through 30" extension

tube.

5. Engage hex nut with hex drive on drill.