10

Aluminum Oxide Aluminum Zirconia Bi-Cut Ceramic

For fast cutting, general purpose discs for

most metal jobs. Best for cold-rolled steel,

stainless steel or metals requiring tough, fast

cutting, long lasting abrasives.

Unique grit pattern is arranged in clus-

ters for faster stock removal and clean-

ing. Ideal for removing paint from cars,

boats, etc. without clogging.

Lasts up to 3 times longer than

aluminum oxide discs. For

general metal working. Ideal

for tough jobs.

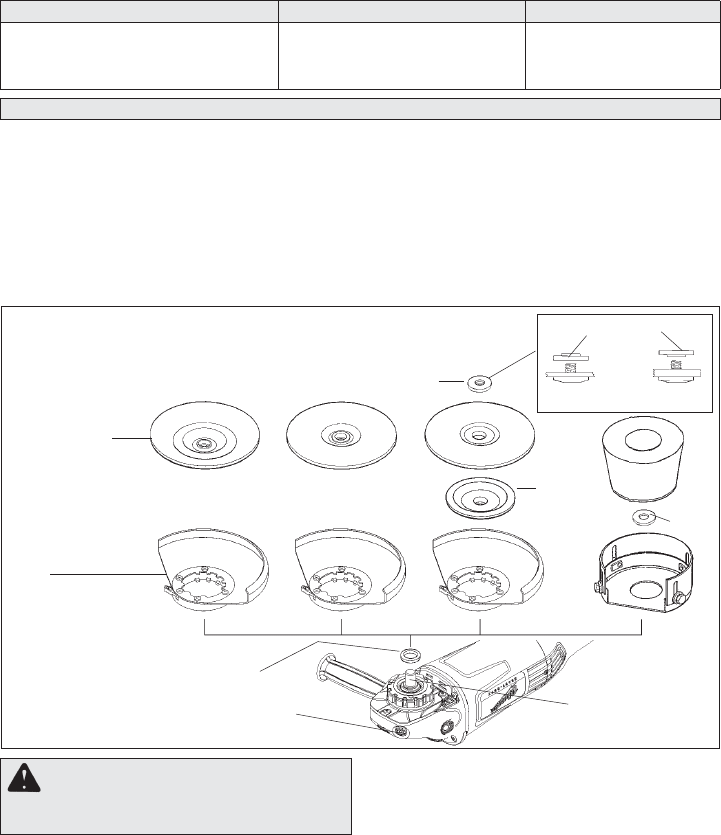

Installing Grinding Wheels

1. Unplug tool and place it upside down on a level

surface as shown. Remove any accessories from

spindle.

2. Thread nylon washer onto spindle. Attach guard

and grinding wheel using Fig. 8 to determine

type and order of assembly (See Fig. 2 and 3 for

attaching guard). NOTE: When installing Type

27 or Type 29 grinding wheels, position disc nut

according to wheel thickness.

Position the guard in the location which offers

USING GRINDING AND CUT-OFF WHEELS

best control and guard protection. For operat-

ing zones that provide maximum protection for

the operator, see Fig. 9. NOTE: When selecting

Type 11 grinding cup wheels, the guard’s skirt

should be adjusted so that no more than 1/8" of

the wheel extends beyond the guard.

3. To tighten, press the spindle lock button while

turning wheel or disc nut clockwise using the

spanner wrench provided.

4. To remove grinding wheel and guard, unplug tool

and reverse procedure.

Grinding wheels

A. Type 28 with hub

B. Type 27 with hub

Type 29 with hub

C. Type 27 with fl ange

Type 29 with fl ange

D. Type 11

Guard

E. Type 28

F. Type 27

G. Type 27

H. Type 11

Fig. 8

Spindle

Disc nut

Nylon washer

Type 27

fl ange

Type 11

fl ange

B

C

D

A

Spindle lock button

FG

H

E

1/4" thick

wheels

1/8" thick or

less wheels

Disc nut position

B

Care of Grinding & Cut-Off Wheels

Grinding and cut-off wheels should be protected from:

• wetness and extreme humidity

• any type of solvent

• extreme changes in temperature

• dropping and bumping

Grinding and cut-off wheels should bestored:

• in an organized way so wheels can be removed

without disturbing or damaging other wheels

• with their safety information

Grinding and cut-off wheels should NOT be:

• dropped

• rolled

• bumped

WARNING To reduce the risk of injury,

the operator should be instructed in the use,

care and protection of grinding wheels.

If any wheel is dropped, rolled, bumped, subjected

to extreme changes in temperature, or has come

into contact with solvents or wetness, discard wheel

immediately.

Troubleshooting

Deep scratches and circular marks can result from:

• Uneven pressure

• Using a partially glazed wheel - especially on

aluminum applications

• Dirt or loose metal on the workpiece

• Failure to constantly move across surface

Bluish discoloration of metal surface indicates:

• Excessive heat caused by circular motion in a

small area

• Excessive pressure

• Use of worn out or glazed wheels

Inspecting Wheels

Always handle wheels carefully to avoid damage.