8 9

1. Lock trigger or remove battery pack.

2. Press in and hold rod release trigger.

3. Grasp plunger rod handle and pull

plunger rod back until the rod tip is just

inside of tool.

4. Release rod release trigger.

5. Position spacer and back cap (fine

threads) onto nose of the tool. The side

of the spacer with the double collar fi ts

inside the back cap.

6. Place backing washer on top of back cap

and thread barrel nut into nose of the

tool as shown. Tighten securely using

the wrench provided.

7. Press rod release trigger and push

plunger rod forward to access the tip of

the on rod.

8. Thread extenstion, plunger, barrel

plunger and nut onto the plunger rod in

the order shown. Tighten securely.

9. Thread barrel into back cap.

10. To remove barrel tube, reverse proce-

dure.

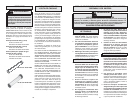

Installing Barrel Assembly (Cat. No. 6562-24) (Fig.5)

6562-24

Fig. 5

Barrel

Plunger rod

Plunger

Backing washer

Back cap

Spacer

Barrel plunger

Barrel nut

Nut

Nozzle cap

Nozzle

Double collar

Extension

Installing Sausage Type Pack

Always check sausage packs for punctures

or damage to the pack before installing. Do

not use a damaged or frozen pack.

1. Lock trigger or remove battery pack.

2. Press in and hold rod release trigger.

3. Grasp plunger rod handle and pull

plunger rod back to allow sausage pack

to fi t inside barrel tube.

4. Insert pack into barrel tube.

5. Cut off end of sausage pack.

NOTE: Before using a partially fi lled

pack, remove any hardened material.

6. Insert nozzle supplied with the sausage

pack into the nozzle cap (coarse thread).

Thread nozzle cap onto the front of bar-

rel tube (Fig. 5).

7. Cut nozzle at an angle and size per

manufacturer's recommendation to

suit the job. A smaller nozzle diameter

requires more force to push the caulk

and reduces battery life.

8. Press in and hold rod release trigger.

9. Push plunger rod handle forward until

plunger is against sausage pack.

10. Release rod release trigger.

OPERATION

Starting and Stopping and Controlling

Speed

1. Pull trigger to dispense material.

2. Increase or decrease pressure on the

trigger to dispense the material. Adjust

the speed dial to select the maximum

speed for proper bead width and mate-

rial feed rate. On the speed dial, "1" is

the slowest speed and "6" is the fastest

speed. The trigger pressure, selected

speed, material type, temperature and

nozzle diameter will all affect the fl ow

rate. When using a tube or pack with a

smaller nozzle diameter use a slower

speed or the material may be forced

around the rear tube seat.

3. Release trigger to stop dispensing material.

NOTE: The plunger will stop automatically

when it has reached the end of the tube.

Locking the Trigger (Fig. 6)

Always lock trigger or remove battery pack

before changing accessories or performing

maintenance. Lock trigger when the tool is

not in use and when storing the tool.

1. To lock the trigger, push trigger lock in

the direction shown. The trigger will not

work when the trigger lock in the locked

position.

2. To unlock the trigger, push the trigger

lock in the direction shown.

WARNING!

When tool is not in use, lock trigger

to prevent the tool from being ac-

cidentally turned on.

Locked

Unlocked

Adjusting Plunger Rod

1. To manually adjust plunger rod, press in

and hold rod release trigger.

2. Grasp plunger rod handle and either

push or pull rod in or out.

3. Release rod release trigger.

NOTE: Keep plunger rod clean of material.

Retracting a plunger that is covered with

material may damage the internal parts of

the tool.

Electronic Overload Protection

The gun is protected by an electronic over-

load protection feature. If too much pressure

is exerted on the tube, the motor will auto-

matically reverse for one second, and then

shut down. This helps to prevent damage to

the tool and the caulk tube or pack.

If the motor shuts off, make sure that:

• Nozzle tip is cut

• Inner seal in the caulk tube is broken

• Hardened material is removed from the

nozzle

• Caulk tube is not damaged or frozen

• Plunger rod is free of caulk/adhesive

materials

Release trigger to allow the electronics to

reset. If the motor continues to shut off, try

another tube of material or take the tool to a

MILWAUKEE Service Center.

Auto-Reverse Mechanism

The auto-reverse feature reverses the plung-

er when the trigger is pressed for more than 1

second and then released. This helps to stop

excess material from continuing to fl ow.

Pulsing the trigger will deactivate the auto-

reverse mechanism and allow for continued

pressure on the tube. This helps maintain a

slower material feed rate.

Fig. 6