page 5

OPERATION

WARNING!

To reduce the risk of injury, wear safety goggles or glasses

with side shields. Unplug the tool before changing accesso-

ries or making adjustments.

Starting and Stopping the Motor

Plug in the tool. To start the tool, squeeze the paddle trigger. Release the

paddle trigger to stop tool.

1. To start the tool, squeeze the paddle trigger.

2. To stop the tool, release the paddle trigger.

Sanding Disc and Grinding Wheel Selection

Use sanding discs and grinding wheels that are:

correct size as written on tool's nameplate.

correct wheel type and grit for the job.

rated at or above the RPM listed in the "WARNING" section on

the tool's nameplate.

Use backing pads, adapters, and other accessories that are:

correct size for tool and for sanding disc or grinding wheel.

rated at or above the RPM listed in the "WARNING" section on

the tool's nameplate.

the proper accessory for the job.

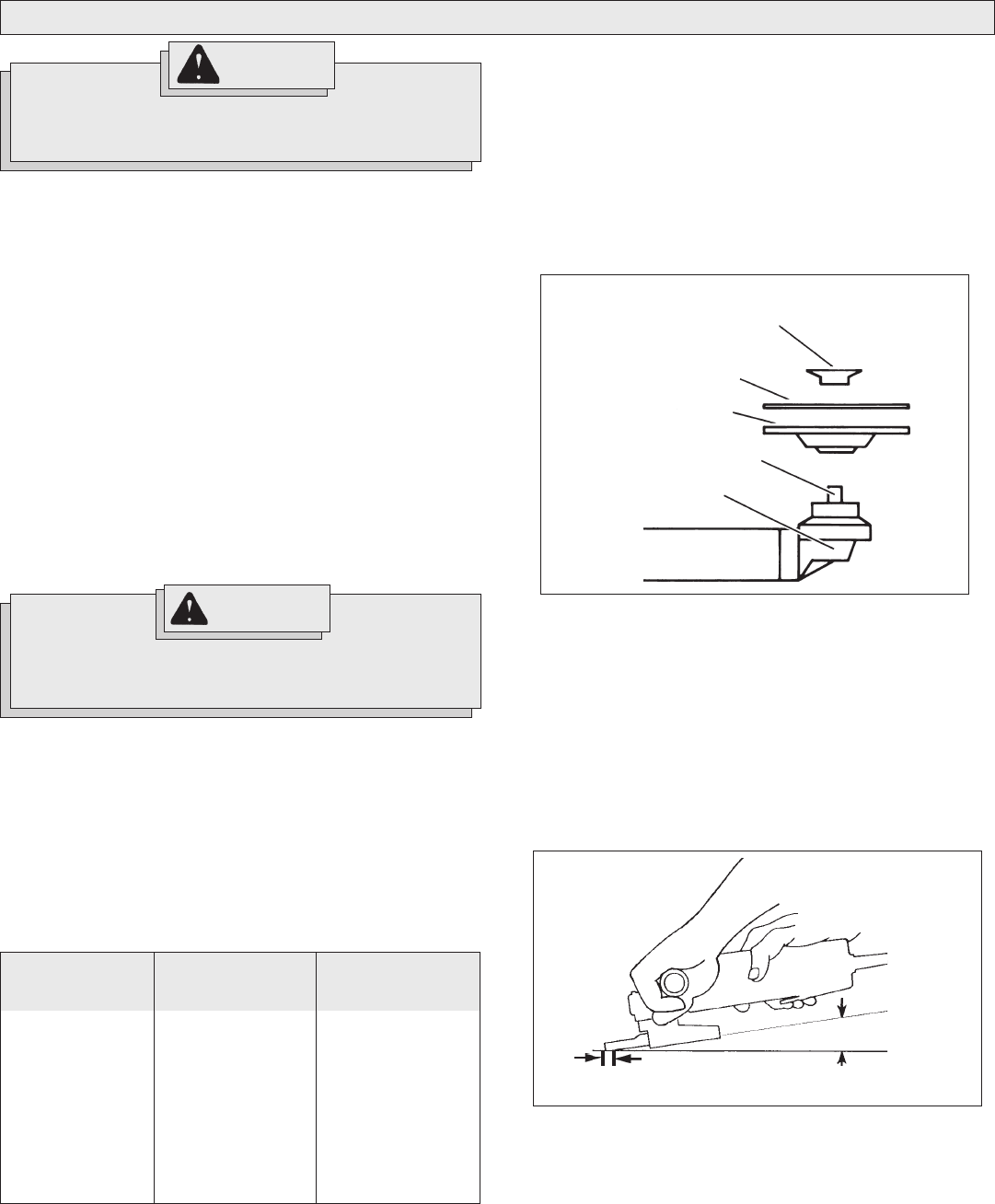

Installing Backing Pad and Sanding Discs (Fig. 1)

1. Unplug tool and place it upside down on a level surface as shown.

Remove any accessories from spindle.

2. Slip backing pad onto spindle with flat side away from gear case.

Place sanding disc on backing pad and secure assembly to spindle

with disc nut.

3. To tighten, press the spindle lock button while turning disc nut clock-

wise.

4. To remove backing pad and sanding disc, unplug tool and reverse

procedure.

Sanding (Fig. 2)

1. Use a clamp, vise or other practical means to hold your work, free-

ing both hands to control your tool. Firmly grasp body of tool and

side handle before starting and while tool is in operation. Allow

sanding disc to come to full speed before beginning to sand.

2. Hold Sander/Grinder at 5° to 15° angle as shown to ensure proper

sanding pressure and control. Too great an angle will result in too

much pressure and could cause excessive wear to the disc and

workpiece. Too small an angle will reduce control.

3. Use long, sweeping, side to side strokes, advancing forward to

produce the desired finish.

Fig. 1

Gear Case

Spindle

Backing Pad

Disc Nut

Sanding Disc

Fig. 2

For best result use only this portion of disc

Hold at a 5° to 15° angle

Ceramic

Lasts up to 3 times

longer than aluminum

oxide discs. For

general metal work-

ing. Ideal for tough

jobs.

Aluminum

Zirconia Bi-Cut

Unique grit pattern is

arranged in clusters

for faster stock re-

moval and cleaning.

Ideal for removing

paint from cars,

boats, etc. without

clogging.

Aluminum

Oxide

For fast cutting, gen-

eral purpose discs

for most metal jobs.

Best for cold-rolled

steel, stainless steel

or metals requiring

tough, fast cutting,

long lasting abra-

sives.

Sanding Disc and Grinding Wheel Material

Sanding discs and grinding wheels are made of various materials and

are designed for different jobs. Be sure that you choose the proper

sanding disc or grinding wheel for the job you plan to do.

Selecting Sanding Discs & Grit

Refer to the table below to select the correct type of sanding disc for

your job. Generally, use 24 or 36 grit for heavy stock removal; 50, 60, or

80 grit for medium stock removal and 120 grit for finishing. Always begin

with a coarse grit, using successively finer grits to obtain the desired

finish. See Catalogor a complete list of MILWAUKEE sanding discs.

To reduce the risk of personal injury and damage to the tool,

use ONLY accessories rated at or above the RPM listed on the

WARNING section of the tool's nameplate.

WARNING!