page 6

Removing Welds or Hammer Marks

When removing welds or hammer marks, limit coarse sanding to the

immediate area. Use successively finer grits to smooth surface.

Cross Sanding

When finishing a surface that has been prepared by a coarse disc or

wheel, sand at right angles to the strokes made by the coarser disc.

Finishing marks left from previous sanding are easily seen and removed

for a uniform finish. Failure to cross sand when changing from a coarse

disc to a finishing disc may result in deep scratches and circular marks.

Finishing Metal

Constantly move across the surface. Work faster on curved surfaces

where contact areas are smaller and pressure is greater. Flat areas may

appear at the end of the stroke when pressure is too heavy. Ease up on

pressure at end of each stroke and when reversing strokes.

Troubleshooting

Deep scratches and circular marks can result from:

Using too coarse a grit

Using a partially glazed disc

Dirt or loose metal on the workpiece

Failure to sand across the grain when changing from coarse

to finishing discs

Failure to use closed coated discs to reduce the problem

of grains working loose and scratching the workpiece

Bluish discoloration of metal surface indicates:

Excessive heat caused by circular motion in a small area

Excessive pressure

Use of worn out or glazed discs

Inspecting Wheels

Always handle wheels carefully to avoid damage. Before installing any

wheel, always inspect it for cracks. If wheel is cracked, discard it to

prevent others from using it.

Care of Grinding & Cut-Off Wheels

Grinding and cut-off wheels should be protected from:

wetness and extreme humidity.

any type of solvent.

extreme changes in temperature.

dropping and bumping.

Grinding and cut-off wheels should be stored:

in an organized way so wheels can be removed without dis-

turbing or damaging other wheels.

with their safety information.

Grinding and cut-off wheels should NOT be:

dropped.

rolled.

bumped.

If any wheel is dropped, rolled, bumped, subjected to extreme changes

in temperature, or has come into contact with solvents or wetness,

discard wheel immediately.

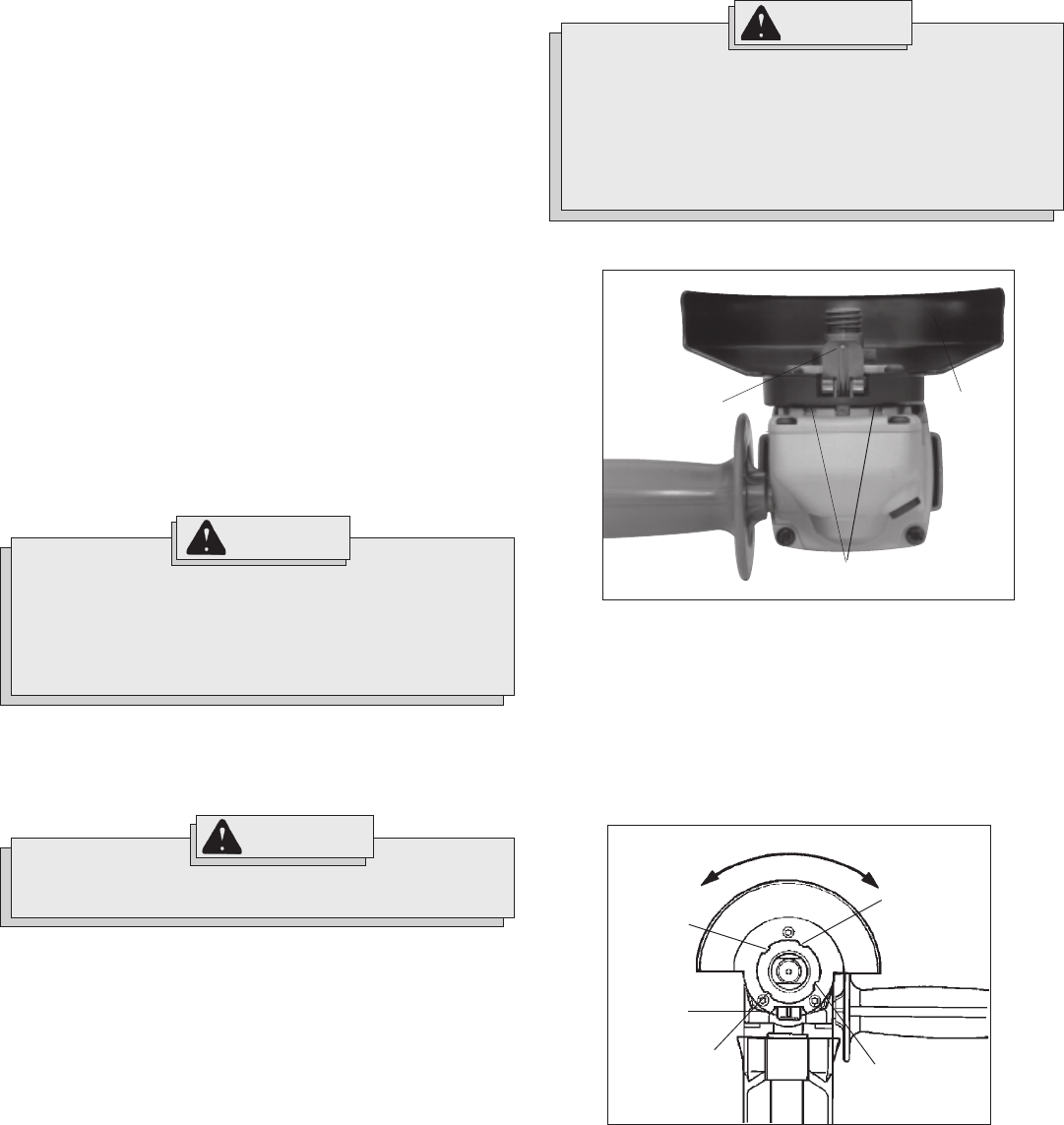

Installing, Removing and Adjusting the Guard (Fig. 3 & 4)

The guard must be used when using the tool as a grinder. The guard

should be removed when using tool as a sander.

1. To install the guard, unplug the tool and place it upside down on a

level surface.

2. Remove any accessories from the spindle.

3. Line up the four tabs with the four slots (Fig. 4) and then press the

guard down onto the tool.

4. Press in the lock lever and rotate the guard to one of the five detent

slots. The lock lever must engage with one of the detents. (Fig. 3)

To reduce the risk of injury:

ALWAYS use the proper guard.

ALWAYS properly install the guard.

ALWAYS hold the tool firmly with both hands before

beginning grinding.

NEVER use a wheel that has been dropped.

NEVER bang grinding disc onto work.

NEVER grind without proper safety equipment.

WARNING!

Only use wheels with Maximum Safe Operating Speed rated

at or above the RPM listed on the WARNING section of the

tool's nameplate. This speed is based on the strength of the

wheel, allowing for a reasonable measure of safety. It is not

meant to imply a best or most efficient operating speed. Do

not exceed the Maximum Safe Operating Speed.

WARNING!

To reduce the risk of injury, the operator should be in-

structed in the use, care and protection of grinding wheels.

WARNING!

Fig. 3

Lock lever

Fig. 4

Tab slot

Tab slot

Tab slot

Tab slot

Lock lever

Guard

Lock lever must engage

one of five detents