PAGE 12 — ESSICK FM9 — PARTS & OPERATION MANUAL — REV. #1 (03/12/01)

AIR SYSTEM

An air pulsation chamber is located on the left side of the unit.

The air is supplied to the chamber from the compressor. The

chamber is eouipped with an air pressure gauge and a safety

valve. The safety

valve is set at the factory at approximately 60

lbs.

HI-VOLUME PUMP

An outstanding feature of the ESSICK MODEL FM9 finishing

machine is that two different size pumps may be used, which

tremendously increases its versatility. A more powerful engine

and transmission are designed into this unit and a hi-volume

pump is furnished as standard. A lo-volume pump is offered as

an optional item. This pump consists of two parts: A smaller rotor

and a smaller stator, which, in turn, may be used when a lower

volume of material is required.

The installation of this pump is very easy because all parts are

interchangeable. It is only necessary to remove the rotor pin,

which fastens the rotor to the connecting rod located at the bottom

of the material hopper, and then thread out the stator tube with

the rotor encased, and install the lo-volume pump in the same

manner. The installation is made easier by threading the rotor

into the stator tube prior to starting assembly.

Fireproofing is one application where the hi-volume pump is of

great advantage. Competitive machines available for fireproofing

are twice the price of this versatile machine. Another purpose for

which the machine can be employed is the application of

browncoat. The hi-volume pump will apply approximately 14

sacks of gypsum hardwall material per hour.

To obtain maximum volume we suggest not to use more than 75

feet of 1-1/2" hose (actual pump volume is slightly under 2 c.f.m.).

PARTS LIST AND OPERATING INSTRUCTIONS

MODEL FM5E- I

THIS IS A SUPPLEMENT TO THE FM9 OPERATING AND

MAINTENANCE INSTRUCTIONS

READ BOTH SETS OF INSTRUCTIONS BEFORE

OPERATING THIS MACHINE

CAUTION: This machine uses high voltages that can be

dangerous and cause injury. Only qualified electricians should

install power supplies or service the electrical components. Power

supply must be in accordance with local electrical codes and of

adequate size to avoid the possibility of overheating the motors

due to low voltage. Supply line must be at least No. 8 gauge wire

and capable of delivering 35 amperes at 240 volts to control

panel of machine. When cleaning, never spray water on the

electric motor. Do not operate machine in standing water.

COMPRESSOR MOTOR - The 1H.P. compressor motor is

operated by a manual ON-OFF switch on the control panel.

PUMP MOTOR - The 5 H.P. pump motor is operated by a magnetic

starter switch. The magnetic starter is equipped with an overload

heater for motor protection.

A 240-volt system of switches and relays is used to control the

magnetic starter. It is protected by a circuit breaker with a reset

button in the door of the starter box

The air control sleeve valve on the nozzle is the master link in

the system. Connect the air line from the air compressor outlet to

the inlet on the control block next to the sleeve valve. This line

has air blowing out of it when the compressor is running. The

other air line runs from the sleeve valve to the pressure switch

inlet on the machine.

In operation, the sleeve valve operates the pressure switch. When

the sleeve valve is in the CLOSED position, air pressure is

applied to the pressure switch. This closes the switch and starts

the pump motor. When the sleeve valve is in the OPEN position,

air pressure is released from the pressure switch. This opens the

switch and stops the pump motor. The pump cannot be operated

without the air controls and air lines. This is a safety feature for

the gun operator and must not be bypassed in any way.

An AUTO-OFF-HAND switch is located on the door of the starter

box. Turning the switch to OFF overrides the sleeve valve control

and stops the pump. Turning the switch back to AUTO or HAND

returns control to the sleeve valve. This switch must never be

wired to turn the pump on without air pressure from the sleeve

valve to the pressure switch.

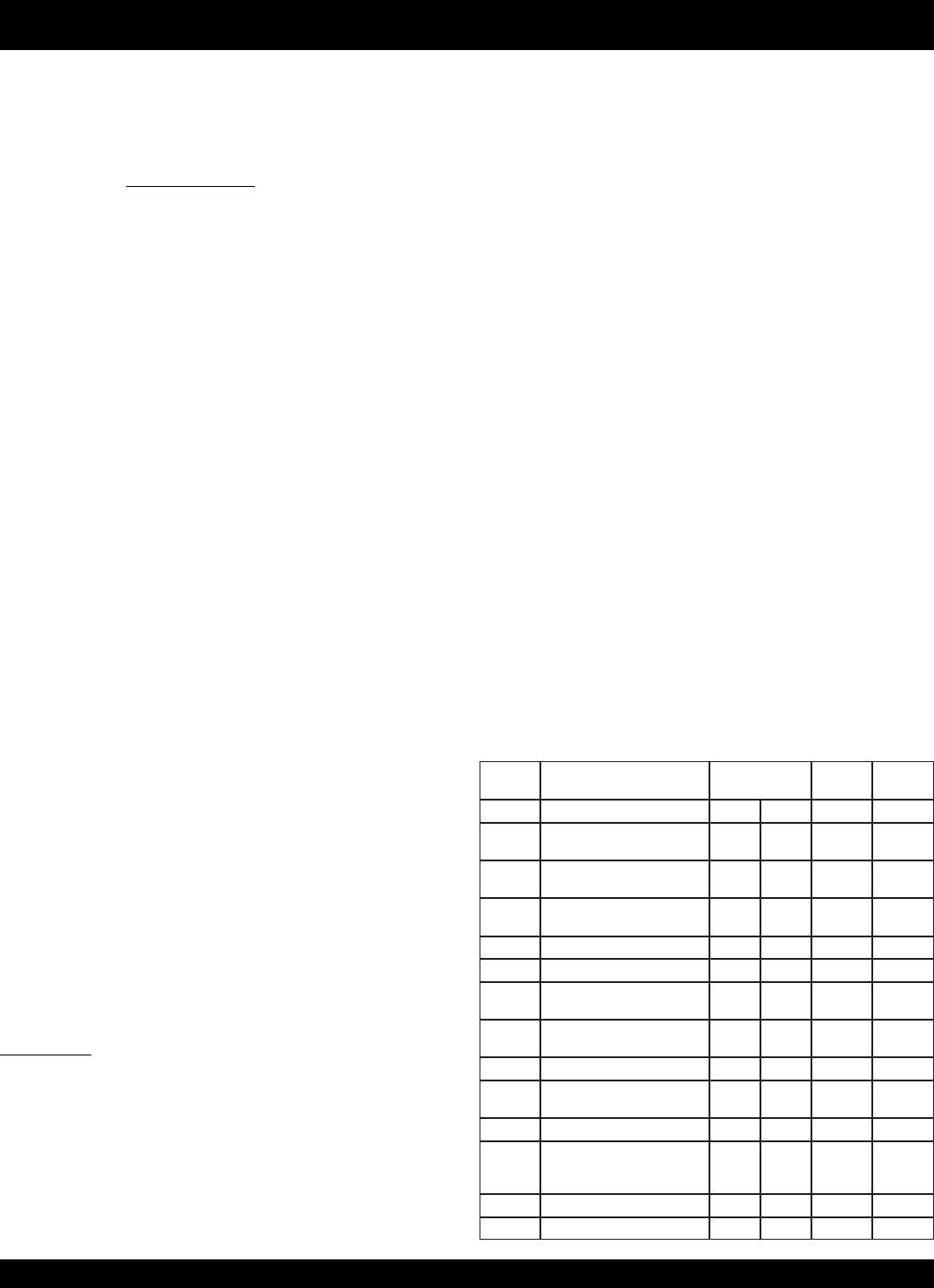

FER NOITPIRCSED ONLAIRES

TRAP

.ON

.YTQ

1 .P.H5–PMUP 303939 1

2

–ROTOMROSSERPMOC

.P.H2/11

960939 1

3

DNAROSSERPMOC

TROPPUSROTOM

127204 1

4

OTGNILPUOC–ESOHRIA

HCTIWSERUSSERP

115104 1

5 YLBMESSABAC 717204 1

6 ROTOMPMUP–YLLUP 862109 1

7 –HNIHSUBYELLUP

ROTOMPMUP

554109 1

8

-YELLUP

ROTOMROSSERPMOC

901109 1

9 HCTIWSERUSSERP 410049 1

01

ROTCENNOCDEGNALF

TELNI

450049 1

11 YDOBROTCENNOC 350049 1

21

RETRATSCITENGAM

DAOLREVOTUOHTIW

RETAEH

146049 1

31 HCTIWSROTCATNOC 800049 1

41 RETAEHDAOLREVO 142049 1

FM-9 — OPERATIONS