PAGE 18 — MQ-WHITEMAN FS1 CONCRETE SAW — PARTS & OPERATION MANUAL — REV. #3 (04/24/03)

CCC

FS 1 CONCRETE SAW — GENERAL INFORMATION

UNDER CARRIAGE SYSTEM

A jig welded heavy steel gauge under carriage chassis assembly

supports the saw in tracking, pivoting and stabilization. Two rear

wheels (8" x 2.0" x 3/4") and two front wheels (4" x 2.0" x 3/4")

supports the chassis. The entire assembly pivots about the rear

carriage and is lubricated through 90-degree grease fitting in

the rear axle tube. [See page 38, Under Carriage Assembly]

BLADE DRIVE SYSTEM

A rugged blade shaft assembly has been specifically designed

to support the optimum distribution of torque from the engine

shaft to the blade shaft, and to ensure minimal vibratory conditions

on the tips of the shaft. Balanced engine & blade shaft pulleys

are connected to their respective shafts. Two premium V-belts

connect the engine pulley to the blade shaft pulley. The 1-1/4"

diameter blade shaft is supported by two self-aligning pillow

block bearings, and is designed for left and right hand cutting.

[See page 40, Blade Shaft Assembly]

BLADE GUARD ASSEMBLY

The two-piece heavy gauge 14" blade guard is designed with a

water system to meet the challenges of wet cutting operations. A

fluted floodwater manifold assembly supplies optimum volume

and dispersal of water to both sides of the diamond blade for wet

cutting applications. The sizable (6") fluted tubes that direct the

floodwater resist clogging and are easily removed for

maintenance. The blade guard has a convenient "flip-up" front

cover for easy blade changes, and is spring tensioned for positive

up/down positioning. The blade guard may be oriented for left or

right hand cutting.

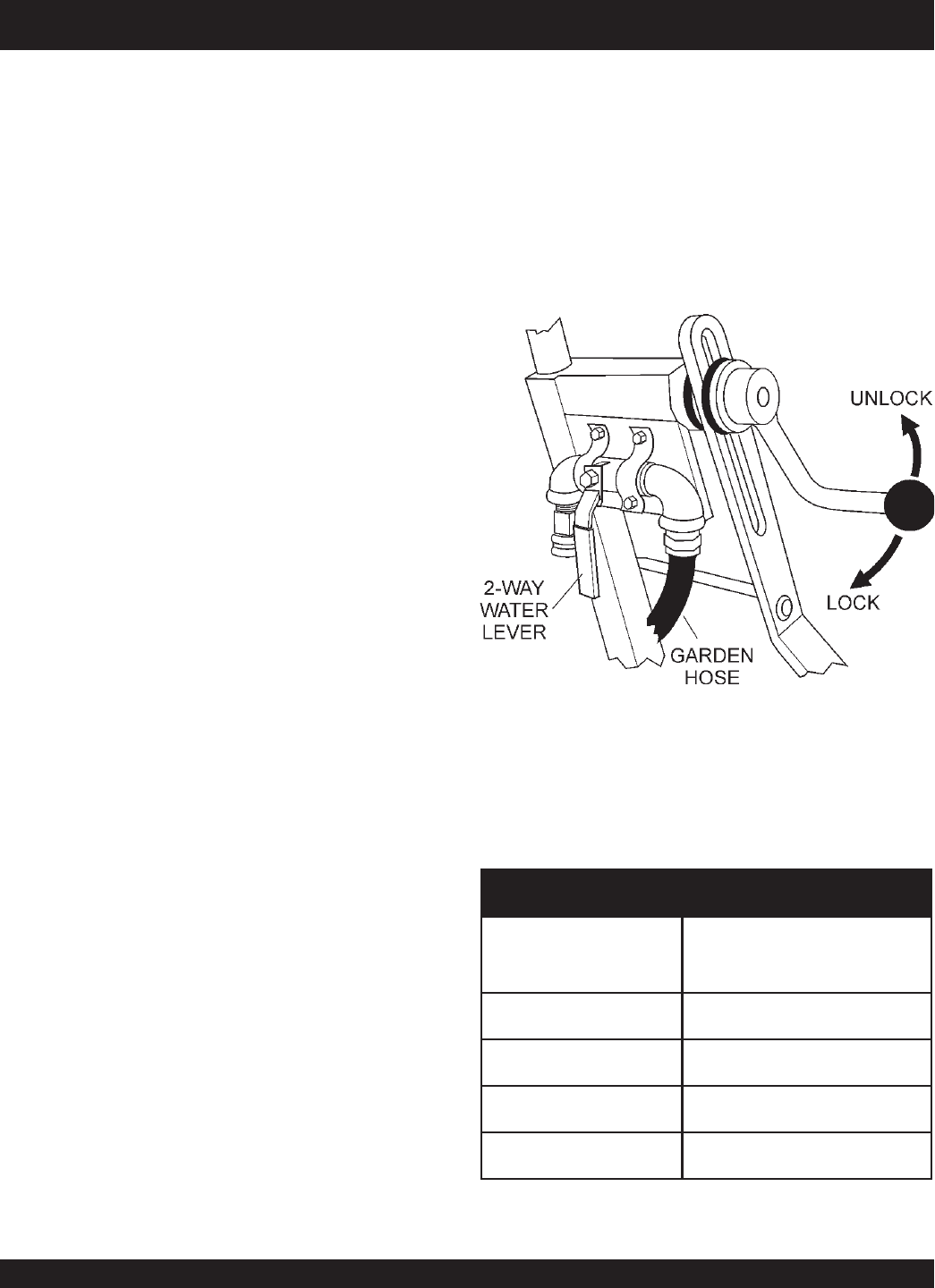

WATER SYSTEM

The FS1 Series employs a water system that provides floodwater

to the blade. Two 6" fluted tubes are connected via a manifold,

and are oriented inside the blade guard to provide optimum

water volume and dispersal to both sides of the blade. A standard

"garden hose" hookup valve connects the water source to the

saw, and a 2-way water lever (ON/OFF) is conveniently located

for the operator. [See Figure 6 and page 48]

MANUAL RAISE/LOWER SYSTEM

A positive locking mechanical raise and lower spring tension

assembly supports elevation cycling operations. A rotating ball

handle permits the engage/disengage process, and the tension

spring assists the operator with smooth blade entry and egress.

Blade orientation is referenced on the front face of the handle

bar support tube and is calibrated for 12", 14", 16" and 18"

diamond blades. [See Figure 11 and page 22]

NOITCELESEDALB.4ELBAT

edalBdnomaiD

).nI(retemaiD

tuCfohtpeD

"21 "8/53

"41 "8/54

"61 "8/55

"81 "8/56

Figure 6. Water Connection/Manual/Raise Lower

Assembly