MP1 — OPERATION AND PARTS MANUAL — REV. #3 (03/29/10) — PAGE 31

MAINTENANCE (SAW)

CAUTION:CAUTION:

CAUTION:CAUTION:

CAUTION:

When loosening the handle lock, hold onto

the front of the motor/engine plate handle to

prevent the plate from raising rapidly, possible

causing the saw to become unstable. Let the

plate raise slowly. When removing the spring

from the pivot shaft, MAKE CERTAIN the motor/engine plate is

supported to prevent the cutting head from dropping.

13. Replace the spindle bearings as soon as they begin to make

any strange noises. Worn bearings can destroy blades very

quickly.

14. Grease pivot bearings periodically.

CUTTING HEAD ALIGNMENT (BLADE)

Make certain the

cutting head

is aligned properly. Misalignment

can adversely affect blade life. The motor/engine plate is slotted

so adjustment to the blade can be made as needed. The left side

has vertical slots, and the right side has horizontal slots. To adjust

the cutting head either vertical or horizontally perform the

following:

VERTICAL ADJUSTMENT

Remove the motor or engine from the mounting plate. Loosen

the pivot bearing bolts (2) on the left side of the mounting plate.

Move the pivot bearing to the extreme top of the slots in the

mounting plate. Thread a 3/8-16 bolt (adjusting bolt) down

through the hole in the top of the mounting plate. Tighten the bolt

against the bearing.

This will raise the mounting plate. Continue to tighten the bolt

until the blade is perpendicular to the conveyor cart. Tighten the

pivot bearing bolts. Remove the adjusting bolt and reassemble.

HORIZONTAL ADJUSTMENT

Loosen the pivot bearings (2) on the right-side of the mounting

plate. Slide the pivot bearing forward or backwards as needed,

until the blade is parallel with the conveyor cart. Tighten the pivot

bearing bolts.

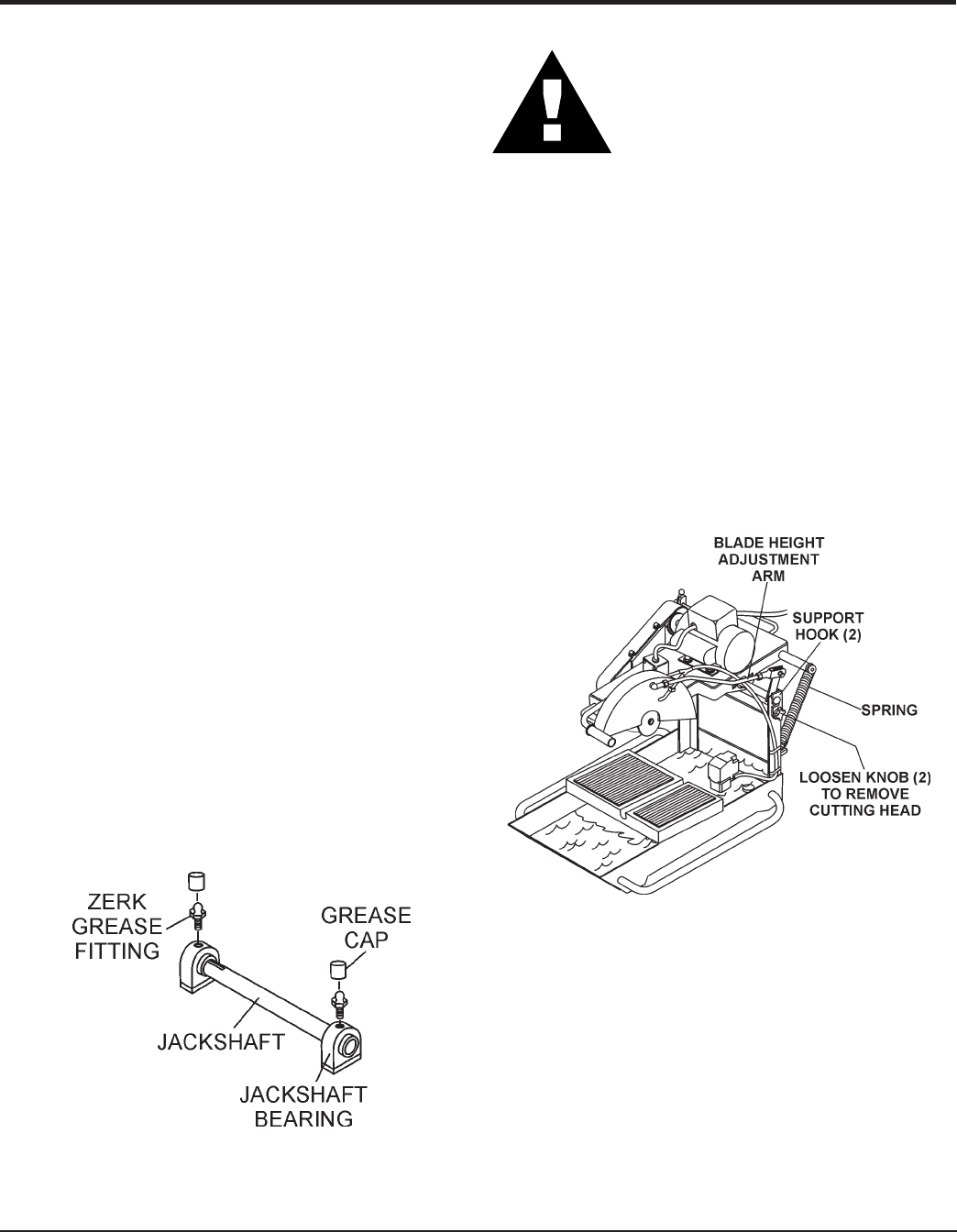

BEARING LUBRICATION CARE

There are two (2) grease points (Figure 30) for the MP1

gasoline

model saw. Use only Premium Lithium 12 based Grease,

conforming to NLG1 Grade #2 consistency. Grease

daily

.

CUTTING HEAD REMOVAL

To remove the cutting head (Figure 31) perform the following:

1. Loosen the knobs (2) located on each side of uprights.

2. Slide the hooks (2) up and away from the pivot shaft.

3. Remove the handle lock that fastens the blade height adjusting

arm to the motor/engine plate. This is accomplished by simply

removing the cotter pin.

4. Disconnect the spring from the pivot shaft by raising the cutting

head until the tension is relieved from the spring.

5. To reassemble the cutting head, reverse these steps.

Figure 31. Cutting Head Removal

Figure 30. Zerk Fittings (Lubrication)