PAGE 22 — MVH-200GH PLATE COMPACTOR — OPERATION & PARTS MANUAL — REV. #2 (09/22/06)

Hydraulic Oil

1. Check hydraulic oil in every 100 hours of operation. With

handle bar positioned vertically (storage position), remove

oil level check plug (Figure 23) from the top of hydraulic

pump and check for proper oil level.

2. Replace hydraulic oil after first 200 hours and in every 1,000

hours of operation.

Figure 23. Oil Level Check Plug

MVH-200GH — MAINTENANCE

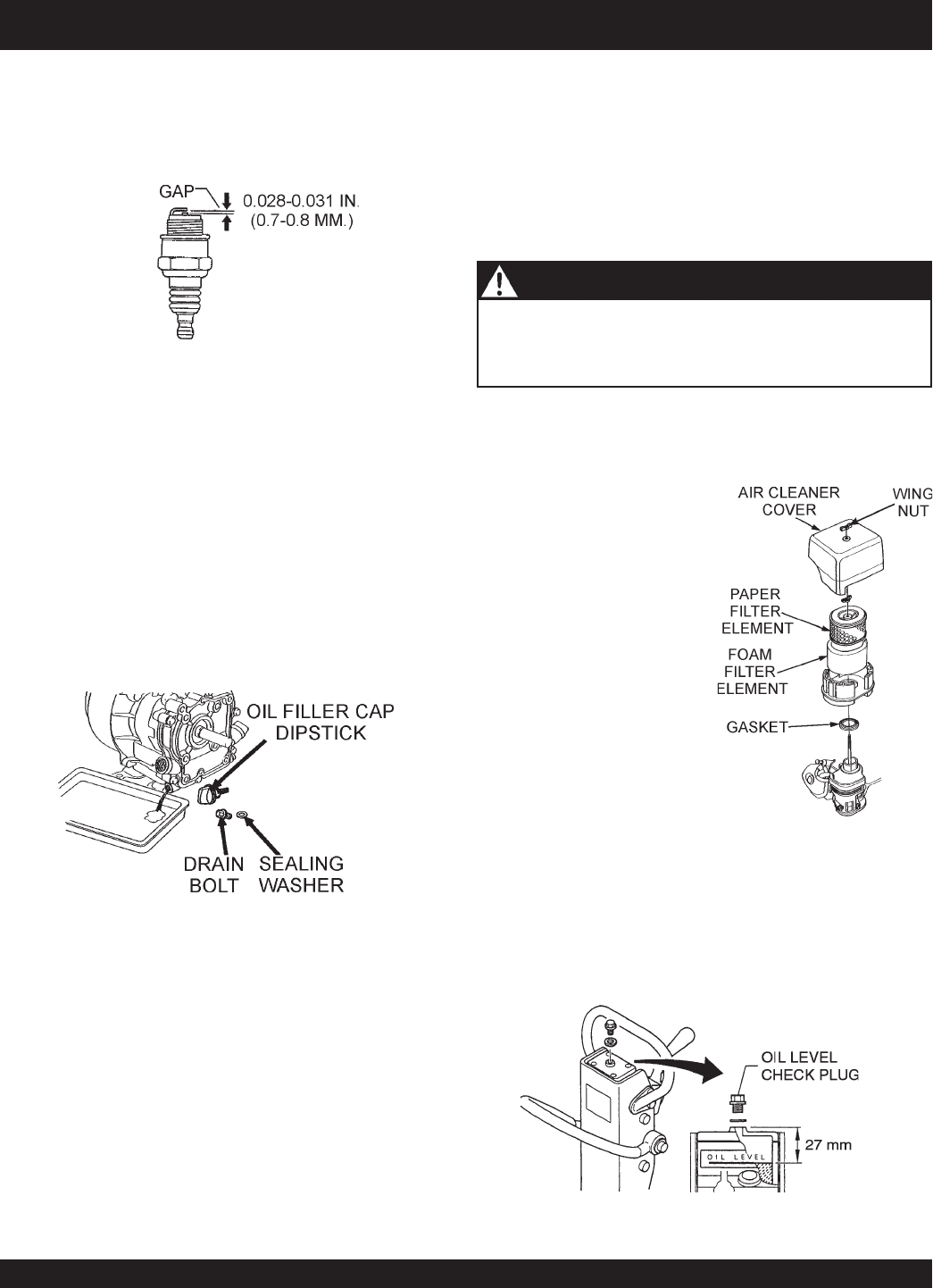

Engine Oil Replacement:

1. Replace engine oil, first in 25 hours of operation and every

50 to 100 hours afterwards.

2. Drain the engine oil when the oil is

warm

as shown in

Figure 22.

3. Remove the oil drain bolt and sealing washer and allow the

oil to drain into a suitable container.

4. Replace engine oil with recommended type oil as listed in

Table 3. Engine oil capacity is 1.16 quarts (1.1 liters).

DO NOT overfill.

5. Install drain bolt with sealing washer and tighten securely.

Air Filter:

1. Remove the air cleaner cover and foam filter element as

shown in Figure 23.

2. Tap the paper filter element (Figure 23) several times on a hard

surface to remove dirt, or blow compressed air [not exceeding

30 psi (207 kPa, 2.1 kgf/cm

2

)] through the filter element from the

air cleaner case side.

Figure 23. Engine Air Filter

Figure 22. Engine Oil (Draining)

Spark Plug:

1. Remove and clean the spark plug (Figure 21).

2. Adjust the spark gap to 0.028 ~0.031 inch (0.6~0.7 mm). This

unit has electronic ignition, which requires no adjustments.

Figure 21. Spark Plug Gap

NEVER brush off dirt. Brushing will force dirt into the fibers and

cause poor performance in your air filter. Replace the paper filter

element if it is excessively dirty.

3. Clean foam element in warm, soapy water or nonflammable

solvent. Rinse and dry thoroughly. Dip the element in clean

engine oil and completely squeeze out the excess oil from the

element before installing.

CAUTION - Cleaning the Engine Air Filter