R2000H RIDE-ON STATIC ROLLER — OPERATION & PARTS MANUAL — REV. #4 (07/24/08) — PAGE 15

R2000H — GENERAL INFORMATION

The forward-reverse control lever operates the hydrostatic pump

which governs the roller speed and direction of travel. The speed

in which movement of this lever is made is directly related to the

amount of pressure that is applied to the travel lever in each

direction. Travel speed is infinitely variable from 0 to 4 mph. The

neutral position of this lever will cause the roller to stop.

The R2000H roller has been designed for asphalt application

and compaction of granular soils used in site preparation. Use

the machine only for the purpose intended and by experienced

personnel who understand this operating manual and all safety

decals. Typical applications for this roller are driveways, patch

work and road repairs.

POWER PLANT

The R2000H roller is powered by a Honda GX240K1QAE2, air-

cooled, gasoline engine rated at 7.1 hp @3,600 rpm. The engine

features a side-mounted muffler designed to direct engine

exhaust away from the operator. In the event of low oil, this engine

has a built in "

oil alert system

" that will shut down if the engine

oil level reaches an unsafe operating level.

SPRINKLER SYSTEM

A 21 gallon (79.5 liters) water tank with a gravity feed spray bar

is provided for wetting the roll for asphalt pavement rolling.

The water system is fully adjustable from the operator’s position

by adjusting the valve in the floor.

Water can be added to the front and rear rollers. Thirty gallons

(250 lbs.) of water can be added to the front rollers, 51 gallons

(427 lbs.) to the rear roller.

Before starting an asphalt rolling job, be sure all spray bar holes

are clear of dirt or foreign matter and are working. Always use

clean fresh water in the water tank. To prevent rust and foreign

debris from clogging the spray bar holes, drain and flush water

tank and spray bars every 30 days.

LIFTING THE ROLLER

When lifting of the roller is required, attach a suitable

hook or shackle to the

lifting eye

of the roller. These

lifting points (4) are marked by a lifting hook decal. Make

sure the lifting device is capable of lifting 4,000 lbs. (1,814 Kg.).

DANGER:

Before operating the roller, make sure that

personnel and obstacles are free from the

roller’s path. Serious injury or even death can

result!

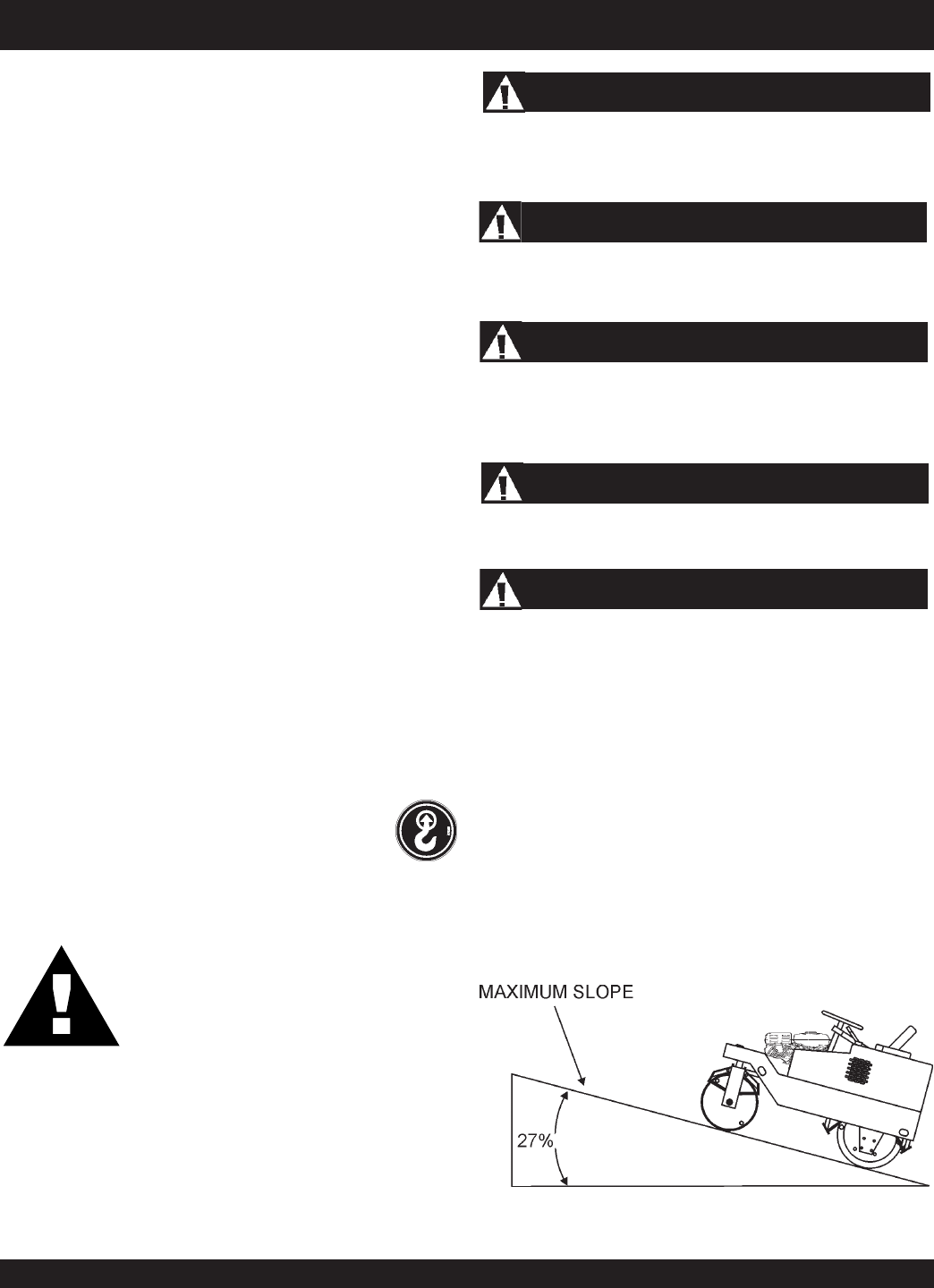

OPERATING ON SLOPES

Special care must be taken when operating the roller on hills or

slopes. There exist the possibility of serious injury to the operator

and severe damage to the roller in the event of a roll over.

ALWAYS operate the roller up and down hills rather than from

side to side. For safe operation hillside slopes should not exceed

15 degrees (27 % grade). See Figure 2 below.

Figure 2. Recommended Slope

NEVER! stand under, or get onto the roller while it is being lifted

or moved.

ONLY! use approved certified lifting devices capable of lifting at

least 4,000 lbs. (1,814 Kg.).

When lifting of the roller is required, only use the provided

lifting

eyes

to lift the roller. Using other sections of the roller for lifting

purposes may cause severe damage to the roller.

Danger

CAUTION

CAUTION

Danger

This roller is

not offered

with a

Rollover Protection Structure

(ROPS). The possibility exists of the roller tipping over causing

severe bodily harm , even death, if side-side operation is used

(Figure 3). DO NOT use this roller for side to side applications.

DO NOT operate this roller on

slippery

or

wet

surfaces.

CAUTION