PAGE 22 — STX-SERIES • RIDE-ON POWER TROWEL — OPERATION MANUAL — REV. #1 (07/16/04)

)

STX-SERIES — MAINTENANCE

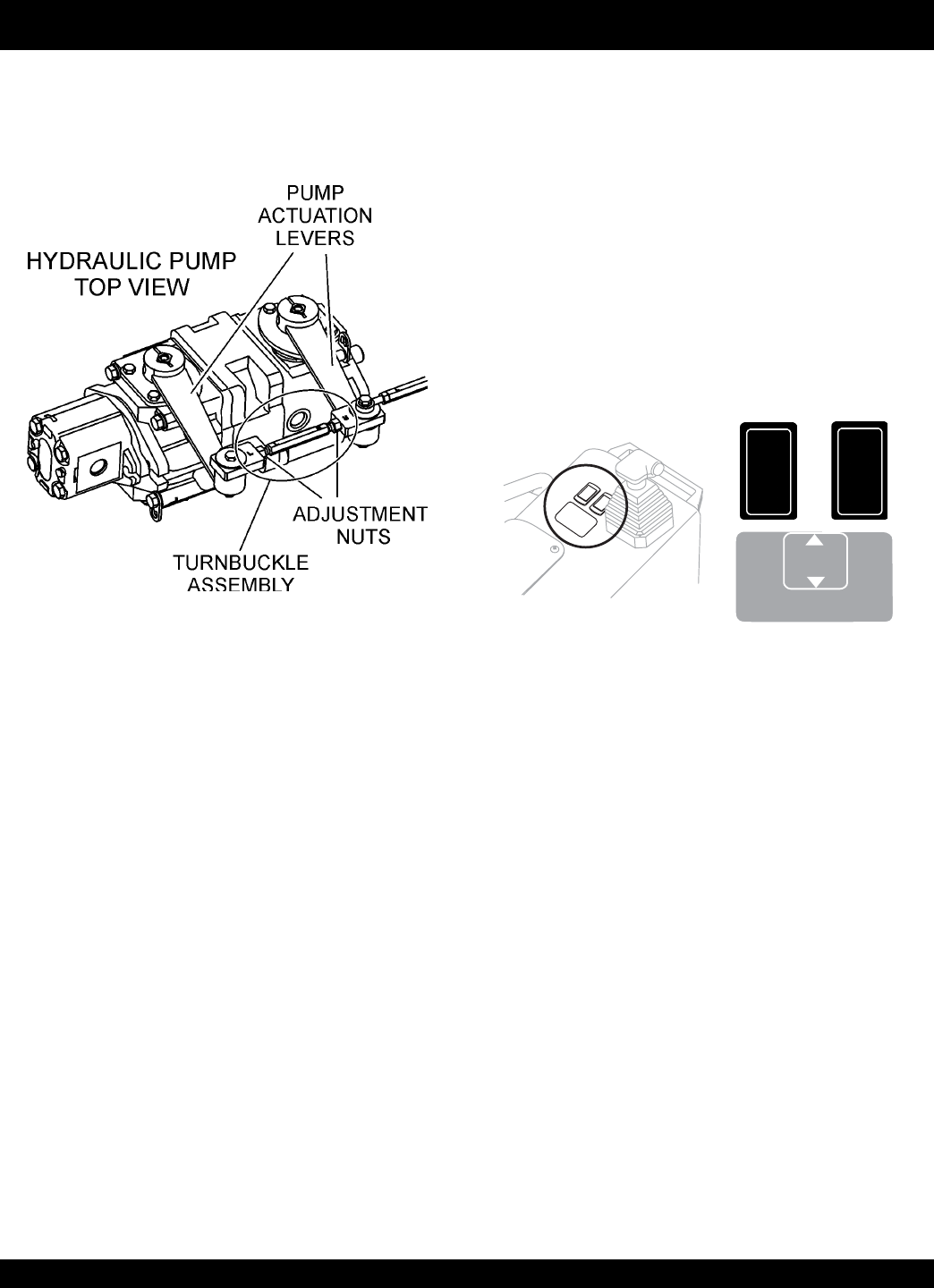

Figure 22. Turnbuckle & Adjustment Nuts

Matching Blade Pitch for Both Sets of Blades

Sometimes it may be necessary to match blade pitch between

the left and right sets of blades. There are some signs that this

may be necessary. For example, the differences in pitch can

cause a noticeable difference in finish quality between the left

and right sets of blades. The difference in blade pitch can also

make the machine difficult to control. This is due to the surface

area in contact with the concrete (the blade set with the greater

contact area tends to stick to the concrete more).

To synchronize pitch on both sides, the left blade assembly can

be pitched by itself. By using the electric blade pitch rocker

switches, (Figure 23) the pitch can be syncronized on the left

and the right sides.

■

Is the machine wearing out blades unevenly (i.e. one blade

is completely worn out while the others look new)?

■

Does the machine have a perceptible rolling or bouncing

motion when in use?

■

Look at the machine while it is running, do the guard rings

“rock up and down” relative to the ground?

Watch for the following indications when determining if blade

pitch adjustments are necessary:

Blade Pitch Adjustment Procedure

The maintenance adjustment of blade pitch is an adjustment

that is made by a bolt (Figure 24) on the arm of the trowel blade

finger. This bolt is the contact point of the trowel arm to the lower

wear plate on the thrust collar. The goal of adjustment is to promote

consistent blade pitch and finishing quality.

Figure 23. Blade Pitch Rocker Switches

LEFT

PITCH

ONLY

BLADES T O BE FLA T

WITH FLOAT PANS

TWIN

PITCH

LESSPITCH

MOREPITCH

This rod is basically a turnbuckle (Figure 22). Rotating it in one

direction increases the length and corresponding trowel speed.

Rotating it the opposite direction decreases the length and trowel

speed. The right side trowel speed should be within 3 rpm of the

left.

A good starting point in the adjustment process is to adjust the

rod such that both trowels begin to rotate at the same time when

the foot pedal is slowly depressed. This will, generally, get the

speeds fairly close; close enough for use if instrumentation is

unavailable (i.e. on the job site). From this point on, some form of

instrumentation is required to verify that the trowel speeds are

within tolerance. A strobe or magnetic pickup type speed indicator

is recommended to verify the speeds.

The trowel speeds should be adjusted on a dry concrete floor

with the blades pitched flat. Units with the John Deere

turbocharged engine should be set at 130-135 RPM with the

engine at full speed.