7

UNPACKING AND CLEANING

Carefully unpack the machine and all loose items from the shipping container(s). Remove the protective coating from

all unpainted surfaces. This coating may be removed with a soft cloth moistened with kerosene (do not use acetone,

gasoline or lacquer thinner for this purpose). After cleaning, cover the unpainted surfaces with a good quality household

floor paste wax.

The following is an explanation of the operating controls of the Delta 14", 16" and 18" Radial Arm Saws. All users will

benefit by knowing how to set and operate the controls for all cutting operations. To avoid the possibility of damage

to the machine and/or injury to the operator, all user’s should become familiar with the operations and the controls

before turning the machine “ON’.

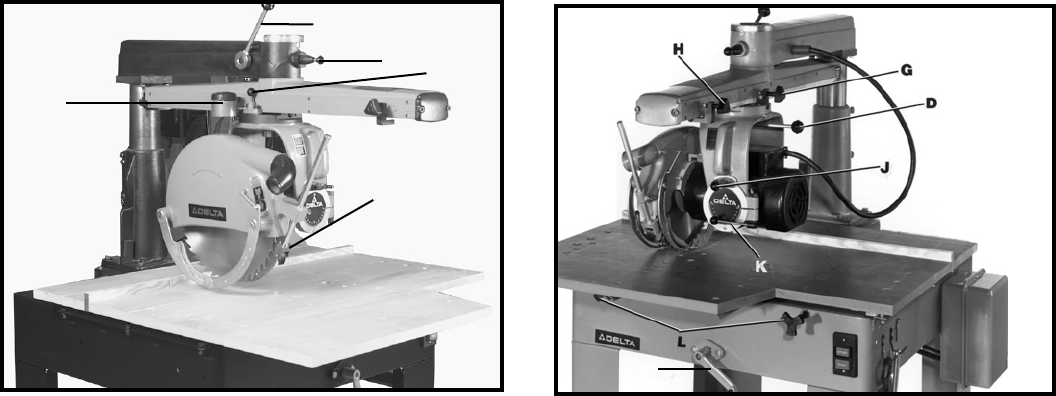

M

A

B

C

Fig. 2

Fig. 3

E

F

A - TRACK-ARM CLAMP HANDLE Fig. 2. Controls

swing of track-arm for all miter cutting operations.

Locks track-arm at any angle for the full 180° rotation.

To rotate track-arm, loosen clamp handle and rotate

arm. The arm will stop at the 0° and 45° positions right

and left. To move the arm past these points the track-

arm index knob (B) must be pulled out.

B - TRACK-ARM INDEX KNOB Fig. 2. Locates 0° and

45° miter position, right and left, of the track-arm

C - YOKE INDEX KNOB Fig. 2. Locates each 90°

position of the yoke for ripping or cross-cutting

operations. When rotating the yoke, the yoke clamp

handle (D) must first be loose.

D - YOKE CLAMP HANDLE Fig. 3. The yoke clamp

handle must be loose when rotating the yoke to the rip

or cross-cut position.

E - ANTI-KICKBACK DEVICE Fig. 2. When ripping,

the yoke is positioned and clamped so that the blade is

parallel to the fence. The rear of the blade guard is

lowered until it almost touches the workpiece. The anti-

kickback rod is then lowered so that the fingers catch

and hold the workpiece. Never rip from the anti-

kickback end of the blade guard.

F - ELEVATING CRANK HANDLE Fig. 3. Controls the

depth of cut in all operations. Turning the crank handle

raises or lowers the over-arm.

G - CUTTINGHEAD CLAMP KNOB Fig. 3. Locks

cuttinghead at any position on the track-arm. When

ripping the cutting clamp knob must be tight.

H - CROSS-CUT STOP Fig. 3. Prevents unnecessary

travel of the cuttinghead on the track-arm. It is

especially useful when performing repetitive operations.

Clamp the stop to the side of the track-arm at a position

which will stop the cuttinghead travel as soon as the

blade cuts through the workpiece.

J - BEVEL INDEX KNOB Fig. 3. Locates 0° and 45°

and 90° positions of the motor when bevel cutting.

When tilting the motor for bevel cutting, the bevel clamp

handle (K) must first be loose.

K - BEVEL CLAMP HANDLE Fig. 3. Controls tilt of

motor for bevel cutting operations. Locks motor at any

desired angle on the bevel scale.

L - TABLE CLAMP KNOBS. Fig 3. Allows the operator

to quickly set the desired fence position.

M - CUTTINGHEAD RETURN ATTACHMENT Fig. 2.

Automatically returns the cuttinghead to the rear of the

track-arm after completion of the cut.

GUIDE TO PARTS