32

CUTTING THE PINS

Cut the end of the pin board according to the instructions on the drawing (Fig. 57A). Steep angles or thin

wood will make for a weak joint. Make this cut on a table saw with the blade beveled, and with the miter

gauge set at 90°.

Clamp the workpiece as you did for the obtuse-angled joint.

Hold the boards together and mark the end of the pin board at the edges of the tails.

The remainder of the steps, including fitting the joint, are identical to the obtuse-angled joint section.

Step 1 -

Step 2 -

Step 3 -

Step 4 -

SETUP

Use the same setup as you would for the obtuse angled joint. Use 180° minus the joint angle for the insert angle

when you make your angled insert or your angled clamping board.

NOTE: If the acute angle and the obtuse angle add up to 180°, use the same setup for both joints.

CUTTING THE TAILS

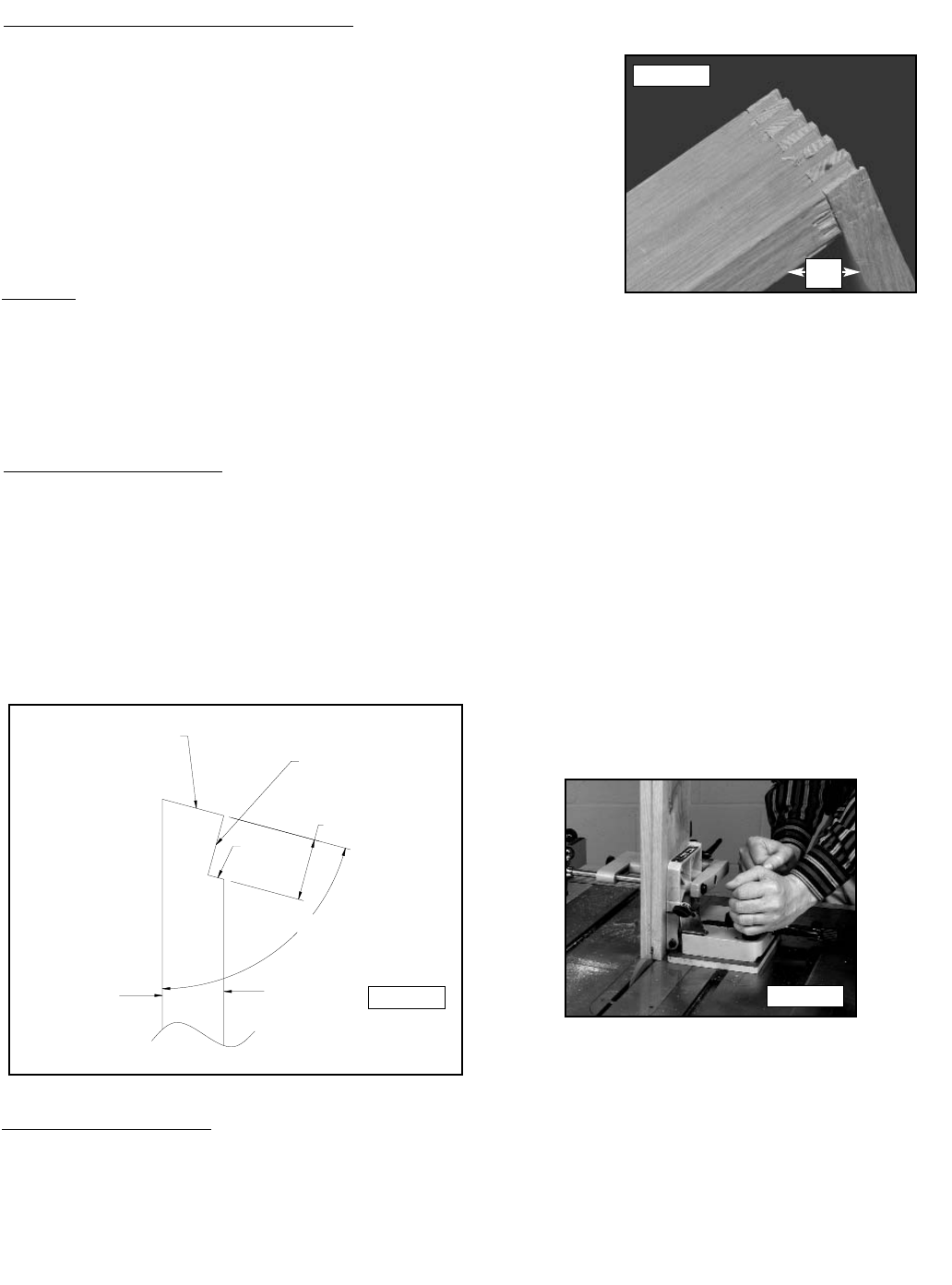

Cut the end of the tail board according to the instructions on the drawing (Fig. 56A). Steep angles or thin

wood will make for a weak joint. Make this cut on a table saw with the blade beveled. Set the miter gauge

at 90° for the first cut and use a tenoning jig for the second cut (Fig. 56B).

Clamp the workpiece as you did for the obtuse-angled joint, except face the outside surface of the board

away from the base of the jig.

Step 3 is identical to Step 5 in "CUTTING THE TAILS" of the obtuse-angled section.

Set the router bit depth to where the step is in the tail board.

Cut the tails and remove the tail board.

Step 1 -

Step 2 -

Step 3 -

Step 4 -

Step 5 -

FIRST CUT

SECOND CUT

THIRD CUT

(IF NECESSARY)

OUTSIDE

SURFACE

OF BOARD

INSIDE

SURFACE

OF BOARD

THICKNESS OF PIN BOARD

ANGLE BETWEEN BOARDS

Fig. 56A

Fig. 56B

ACUTE ANGLED JOINTS

An acute angle joint joins two boards together at an angle less

than 90°. The acute angled joint is very similar in construction to

the the obtuse angled joint and can be used with the obtuse

angled joint to make boxes with angles other than 90°.

Fig. 55A

Joint

Angle