5

OPERATION

MISCELLANEOUS TECHNIQUES

Using these techniques can simplify your dovetailing projects.

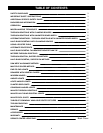

USE A DEAD-BLOW HAMMER

Use a plastic dead-blow hammer to join your workpieces together to help prevent the marring of wood (Fig. 1A).

CHAMFER THE TAIL EDGES

Chamfering the inner tail edges can make the joints go together easier and may prevent damage to the pins (Fig.

1B). Make the chamfers with a file or a chisel. Since the chamfers are located on the inside of the joint, they will be

invisible.

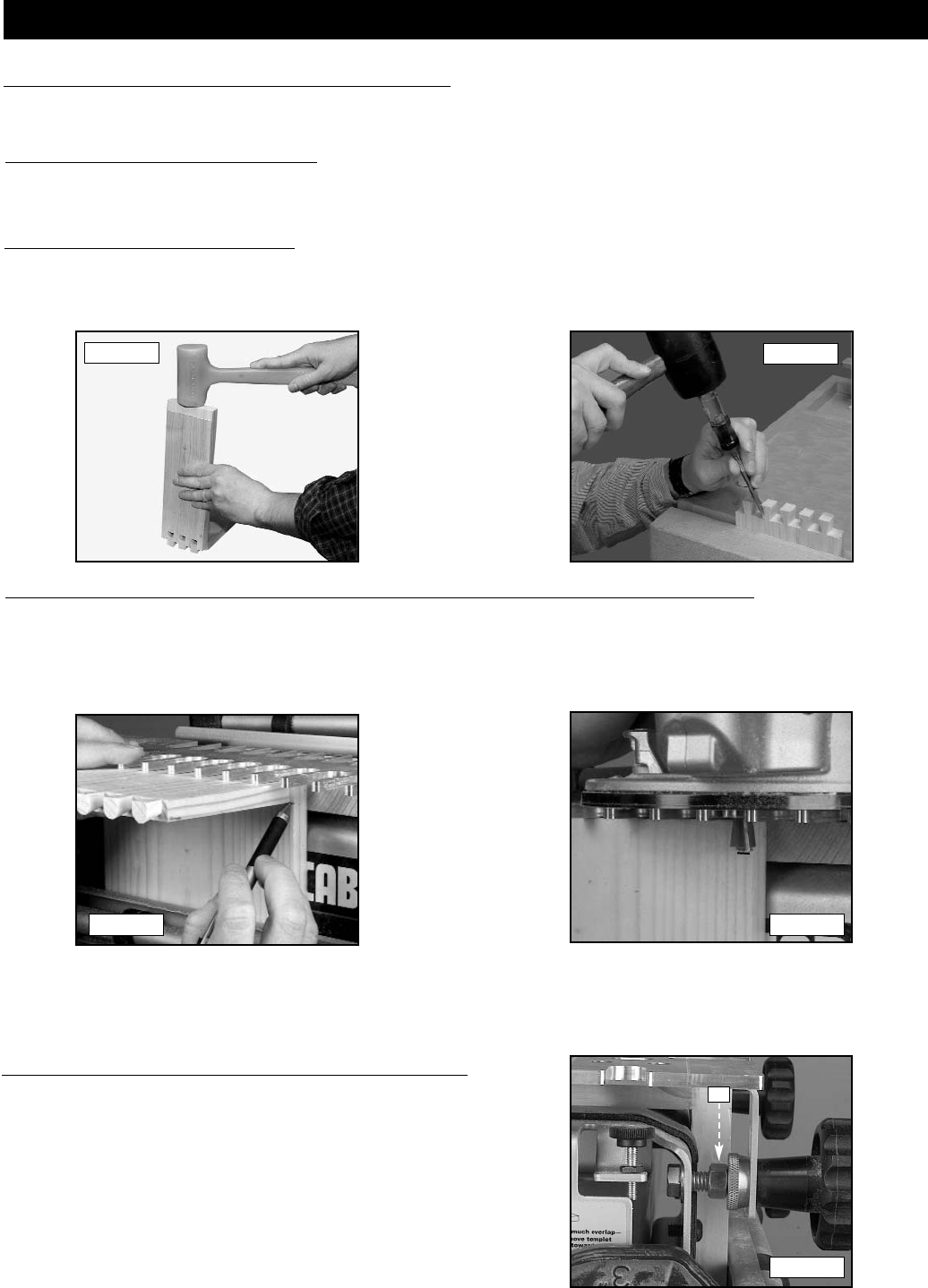

This method of setting your router bit depth on through dovetails or box joints is very accurate for creating pins or

tails that are flush, and is especially good for inlay work. Use a board that is the same thickness as your workpiece

to be joined and draw a line.

ALTERNATE THROUGH DOVETAIL AND BOX JOINT BIT DEPTH SETTING

Set the router on the template and lower the router bit until it reaches the line. Make sure that the scrap material

used in the horizontal position to support the template is at least as thick as the router bit depth-of-cut.

Fig. 1A

Fig. 1B

Fig. 2A

If using the same setup repeatedly, you can use a 3/8"-16 nut (A)

Fig. 3A (not supplied) to keep the brass adjustment knobs from

moving.

STOP NUT FOR BRASS ADJUSTMENT KNOB

Fig. 2B

Fig. 3A

A