35

NOTE: The instructions given here are for templates mounted to the base of the jig. However, this joint can also be

made with templates mounted to angled clamping boards. You must use the angled clamping board for steeper

angles.

Use the following table for setting up your table saw for these cuts:

DESIRED SIDE ANGLE

85°

80°

75°

70°

65°

MITER gauge ANGLE

85.0°

80.1°

75.5°

71.1°

67.1°

BLADE TILT ANGLE

89.6°

88.3°

86.2°

83.3°

79.7°

SETUP

Use the same setup as you would for the obtuse angled joint. Use the blade tilt angle for making the angle insert or

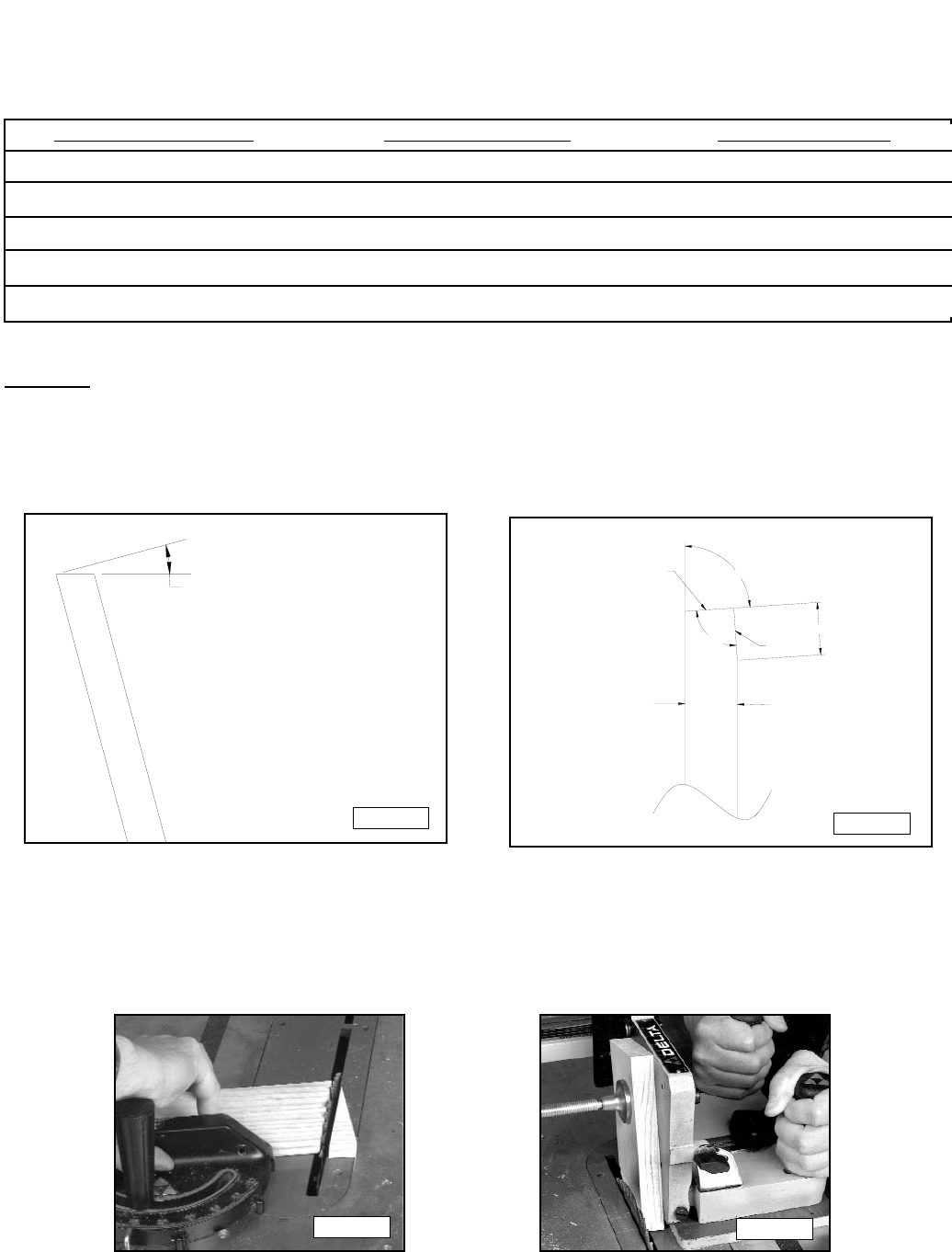

the angled clamping block. Bevel the edges according to the drawing (Fig. 63A).

BEVEL THE EDGES OF THE TAIL AND PIN BOARDS

Fig. 63A

FIRST CUT

SECOND CUT

INSIDE

SURFACE

OF BOARD

OUTSIDE

SURFACE

OF BOARD

BLADE TILT ANGLE

THICKNESS OF PIN BOARD

90.0°

Fig. 64A

Cut the end of the tail board according to the drawing (Fig. 64A). Set the miter gauge and tilt the blade to

the values in the above table. Make the first cut with the board flat on the table surface and guide it with

the miter gauge (Fig. 64B). Make the second cut with a tenoning jig (Fig. 64C).

Step 1 -

Fig. 64B

Fig. 64C