14

ALIGNMENT PLATE (For Narrow Stock)

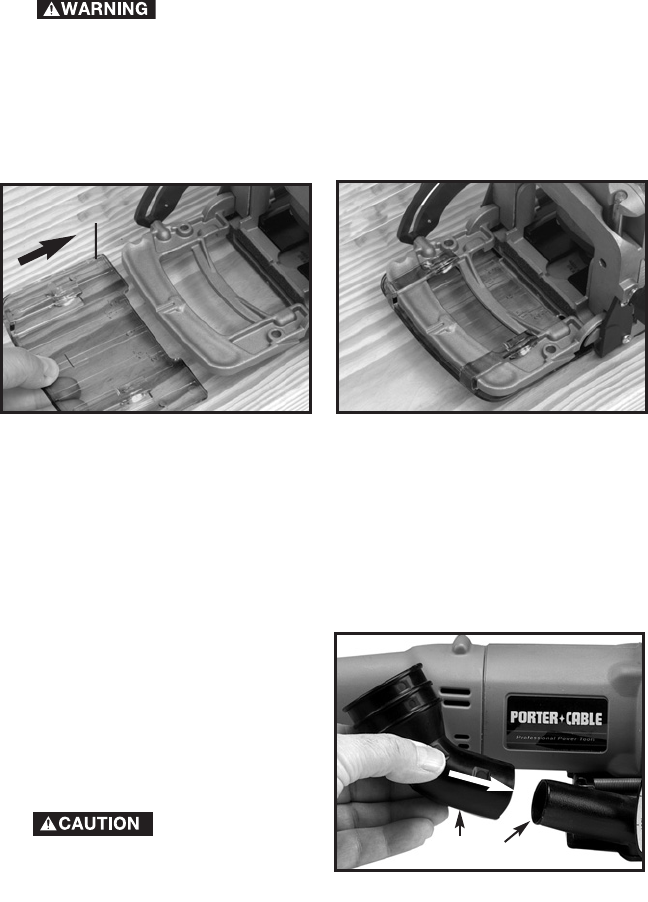

When joining narrow material, it will be necessary to install the alignment

plate (A) Fig. 15, (furnished with tool). The alignment plate provides added

support for narrow material, and has index marks to aid in centering the cut

in the narrow material. Index marks are provided for 1

1

/2" wide, and 2" wide

material. Install alignment plate as follows:

DISCONNECT TOOL FROM POWER SOURCE.

1. Align alignment plate with fence (see Fig. 15).

2. Slide alignment plate onto fence until it is seated (see Fig. 16).

NOTE: When alignment plate is installed: increase tool depth setting

by

5

/32" (to allow for thickness of the alignment plate).

3. To remove alignment plate: lift lightly on the alignment plate and slide off

fence.

“DOUBLE” BISCUITS

The alignment plate may also be used as a spacer to produce a groove that

is wide enough to accept two biscuits. After cutting a groove (or a group of

grooves), in the normal fashion: install the alignment plate and repeat the

cuts. This will double the width of each groove so that two biscuits can be

installed in each groove.

DUST PORT

The tool is equipped with a dust port

(A) Fig. 17. A large volume of sawdust

and chips will be exhausted from this

port during tool operation. A dust bag

(B) Fig. 18 and a dust/chip deflector

nozzle (C) Fig. 17 are furnished. A

standard 1" vacuum hose can be

connected to the dust port to

facilitate dust collection.

Do not operate the

tool without a dust/chip deflector

nozzle and dust bag, or a vacuum

hose, attached to the dust port.

Dust/Chip Deflector Nozzle

The dust/chip deflector nozzle (C) pushes onto the dust port (A) Fig. 17.

Fig. 15 Fig. 16

A

Fig. 17

C

A