10

2. Wear ANSI Z87.1 safety glasses and dust mask.

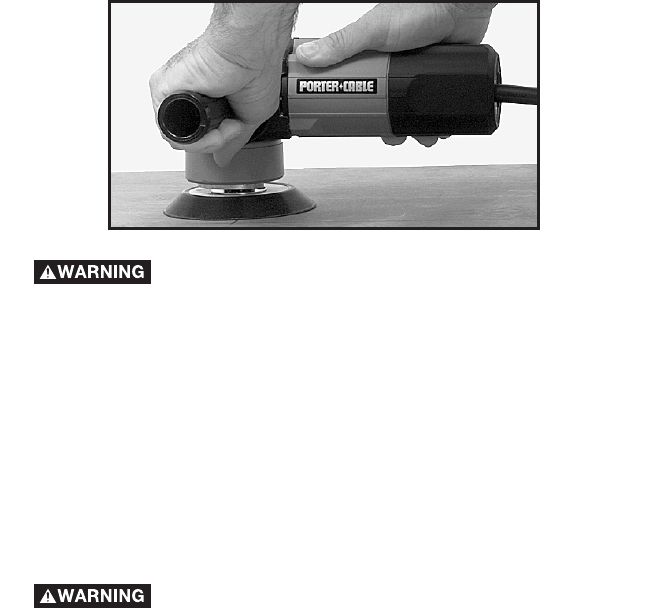

3. Place sander to work (see Fig. 5) with abrasive disc resting FLAT on the

work.

NOTE: The Random Orbit mechanism allows the sander to be

started and stopped with the pad in contact with the work or clear of

the work.

4. Grasp sander firmly and move switch to “ON” position.

5. Keep sanding disc FLAT on work and move sander in long overlapping

strokes. Tipping sander or stopping in one spot can produce an uneven

finish.

6. When finished, stop sander and allow pad rotation to stop completely

before setting sander down.

CHANGING BACK-UP PAD

1. DISCONNECT TOOL FROM POWER SOURCE.

2. Position spindle wrench (A), Fig. 6, (furnished with tool) to engage the

flats on the spindle (B), Fig. 6.

NOTES:

A. It may be necessary to rotate the pad (by hand) to expose the spindle

flats.

B. Fig. 6 shows tool with pad removed for clarity.

C. A spacer (not shown) has been supplied with the 7336SP and 7424 to

add space for the backup pad to clear the eccentric plate screws

(C) Fig. 6. Remove the spacer from the package and mount it on the

shaft before applying the backup pad.

3. While holding the spindle with the wrench, rotate the pad

counterclockwise (by hand) to remove.

4. To install pad, reverse the above procedure.

Fig. 5