9

6. DO NOT apply additional pressure,

allow the polisher to work under its own

weight.

7. Do not mix products (wax, polish,

cleaner, etc.) on the same pad. Label each

pad to prevent future confusion.

8. The polishing pad is designed for

product application only. Remove product

residue with a soft cotton towel.

INSTALLING/REMOVING ABRASIVE DISC

1. DISCONNECT TOOL FROM POWER SOURCE.

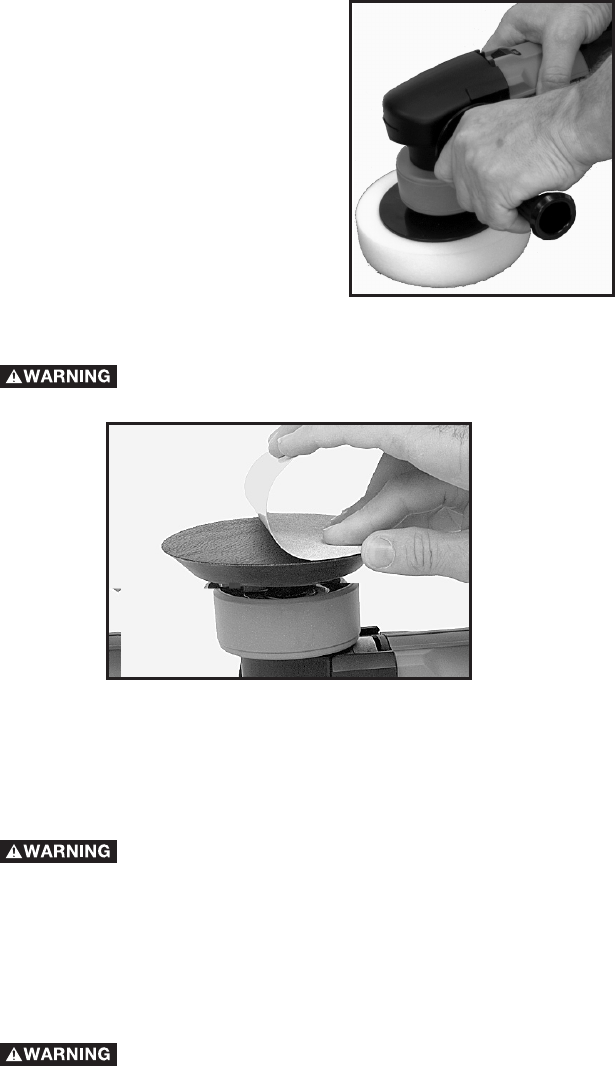

2. Place machine on workbench with pad up (See Fig. 4).

3. Clean dust from pad face.

4. Tear a new abrasive disc from roll and position disc to the sander pad.

5. Press disc firmly onto pad.

6. Position machine with abrasive contacting scrap material. Start machine

and operate momentarily while exerting firm pressure to seat disc to pad.

Failure to properly seat disc to pad may result in disc

being thrown from pad causing personal injury.

7. To remove disc, peel disc away from pad.

NOTE: Do not store machine with an abrasive disc installed. Heat

generated by the sanding operation increases the adhesive bond

between the disc and pad. If disc is left on pad for an extended time

after use, it can become difficult to remove.

USING THE SANDER

1. Secure work to prevent it from moving during the sanding

operation. Friction between the sanding disc and work will try to spin work

away from sander and may cause bodily injury.

Fig. 3

Fig. 4