14

TO START AND STOP SAW

1. Make sure swicth is off and power circuit voltage is the same as shown

on the specification plate on the saw. Connect saw to power circuit.

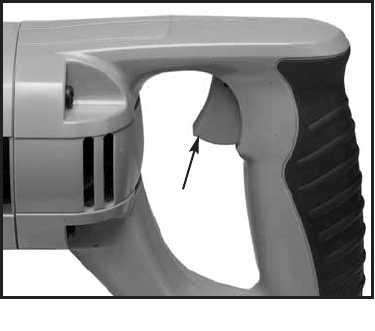

2. Hold saw firmly (see Fig. 13 or Fig.14). Squeeze trigger switch (A) Fig.

15, to start motor. Release trigger to stop motor.

VARIABLE SPEED

The saw is equipped with a variable speed control switch (A) Fig. 15 (0 to

2900 SPM). As the switch trigger is squeezed, the speed of the saw blade

increases.

The lower speeds are recommended for most metal cutting, while the higher

speeds are recommended for wood. A few practice cuts at various speeds

(on scrap material), will aid you in choosing the best speed for obtaining the

desired results on your application.

BEFORE YOU START TO WORK

Select the blade best suited for the material to be cut. For greatest

economy, use the shortest blade suitable for the thickness of the material to

be cut.

Be sure the material to be cut is rigid. Small work pieces should be securely

clamped in a bench vise or with clamps to the work table. As the work

progresses in scroll or curved cut-out pieces, the material may be

readjusted to accommodate the movement of the saw. The saw cuts freely

with only slight feed pressure. Forcing the saw will not make it cut faster.

SAWING WOOD

The variable angle reciprocating saw is used much the same as a hand saw

in that it is moved toward the operator during the cutting operation.

However, since the blade cuts on the up-stroke instead of the down-stroke

as in the case of the hand saw, the good or finish side of the work should

face down during the cutting operation.

Fig. 15

A