15

PLUNGE CUTS

The variable angle reciprocating saw can be used for plunge cutting wood,

plywood, wallboard, and plastic materials.

DO NOT ATTEMPT TO PLUNGE CUT METAL.

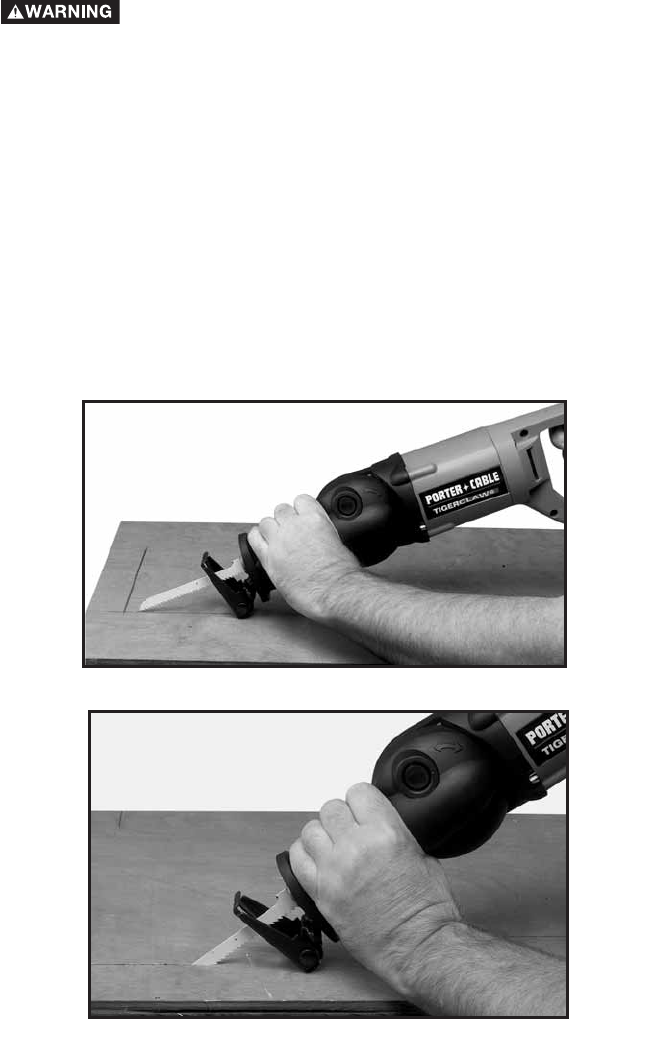

Clearly mark line of cut on the work. Grasp front housing with one hand and

rear handle with the other hand. Choose a convenient starting point inside

the line of cut in waste material area. To start cut, rest saw on pivoting guide

shoe bracket, align blade with the starting point, (blade NOT touching work),

as shown in Fig. 16. Start saw. Using bracket as a pivot point, roll saw

forward by raising rear handle, as shown in Fig. 17. When blade has cut

through the work, continue raising the rear handle until saw is perpendicular

to the work and guide shoe is fully seated on the work surface. Keep saw in

this position and move blade along line of cut.

SAWING METAL

When cutting angle, H-beam, I-beam, channel, etc., start the cut on the

surface where the greatest number of teeth will contact the work. To make a

pocket cut, drill a starting hole first. To extend blade life, cutting oil can be

applied to the work surface along the line of the cut.

Fig. 17

Fig. 16