11

The 7556 may be converted to a conventional straight drive drill by loosening

the back sleeve screw and removing the sleeve and right angle drive from

the drill. Remove the coupling retaining screw (hold spindle with spindle

wrench, turn screw clockwise with a

5

/32" hex wrench) and coupling. Remove

the chuck and washers from the right angle drive and assemble to drill

spindle.

NOTE: Chuck must be firmly seated on spindle before installing

chuck retaining screw.

HOW TO HOLD THE DRILL

The front end of drill may be made live if the tool drills into live

wiring in a wall. TO PREVENT ACCIDENTAL ELECTRICAL SHOCK, DRILL

MUST BE HELD AS SHOWN IN FIG. 3A.

An auxiliary handle (C) Fig. 2, is supplied with each drill.

GENERAL DRILLING

1. Be sure drill bit is securely gripped in chuck. (See INSTALLING AND

REMOVING DRILL BIT).

2. Set REVERSING SWITCH (B) Fig. 2 for clockwise rotation.

3. Make sure work is held securely in vise or clamped in place prior to

starting drilling operation.

Loose work may spin and cause bodily injury.

4. Locate exact center for hole to be drilled and using a center punch,

make a small dent in work.

5. Place tip of drill bit in dent made by center punch, hold drill square with

work, and start the motor.

6. Apply steady, even pressure to keep drill bit cutting. Too little pressure

will keep the bit from cutting and dull the edges due to excessive friction

created by sliding over the surface.

Too much pressure may cause the bit to break or overheat

resulting in bodily injury or damaged drill bits.

Fig. 3

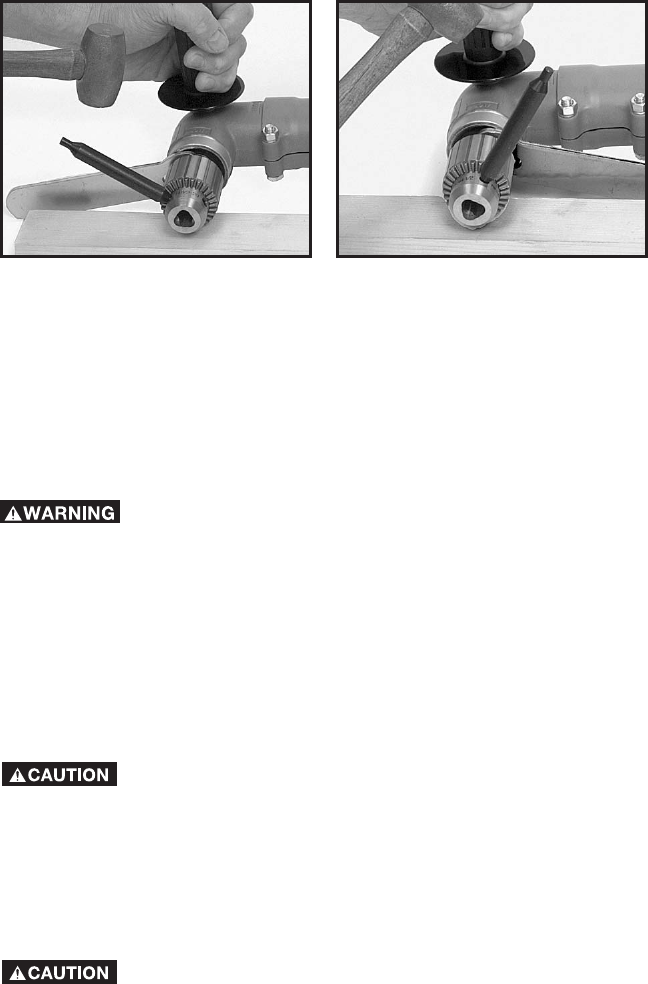

REMOVE CHUCK

INSTALL CHUCK