7

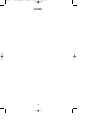

INSTALLING AND REMOVING DRILL

AND SCREWDRIVER BITS

1. CAUTION: Always set reversing button

to center (locked OFF) position when

installing and removing bits.

2. The three-jaw chuck is designed for

self-centering of the bit. Open jaws large

enough by turning outer sleeve (A) Fig. 2,

counterclockwise, when viewing the chuck

from the bit end, so that bit shank can be

inserted easily.

3. Clean and insert smooth end of bit as far as it will go into the chuck, or

up to the flutes for small bits.

4. While holding the bit with one hand, turn outer sleeve (A) Fig. 2, clockwise

until the bit is gripped in the chuck.

5. Tighten chuck by holding chuck ring (B) Fig. 2, with one hand while

turning outer sleeve (A) clockwise with other hand. Tighten securely.

WARNING: Do not operate drill motor while installing or removing

bits. Operating drill motor can cause bit to be thrown from chuck

causing personal injury.

6. To remove bit, reverse foregoing procedure.

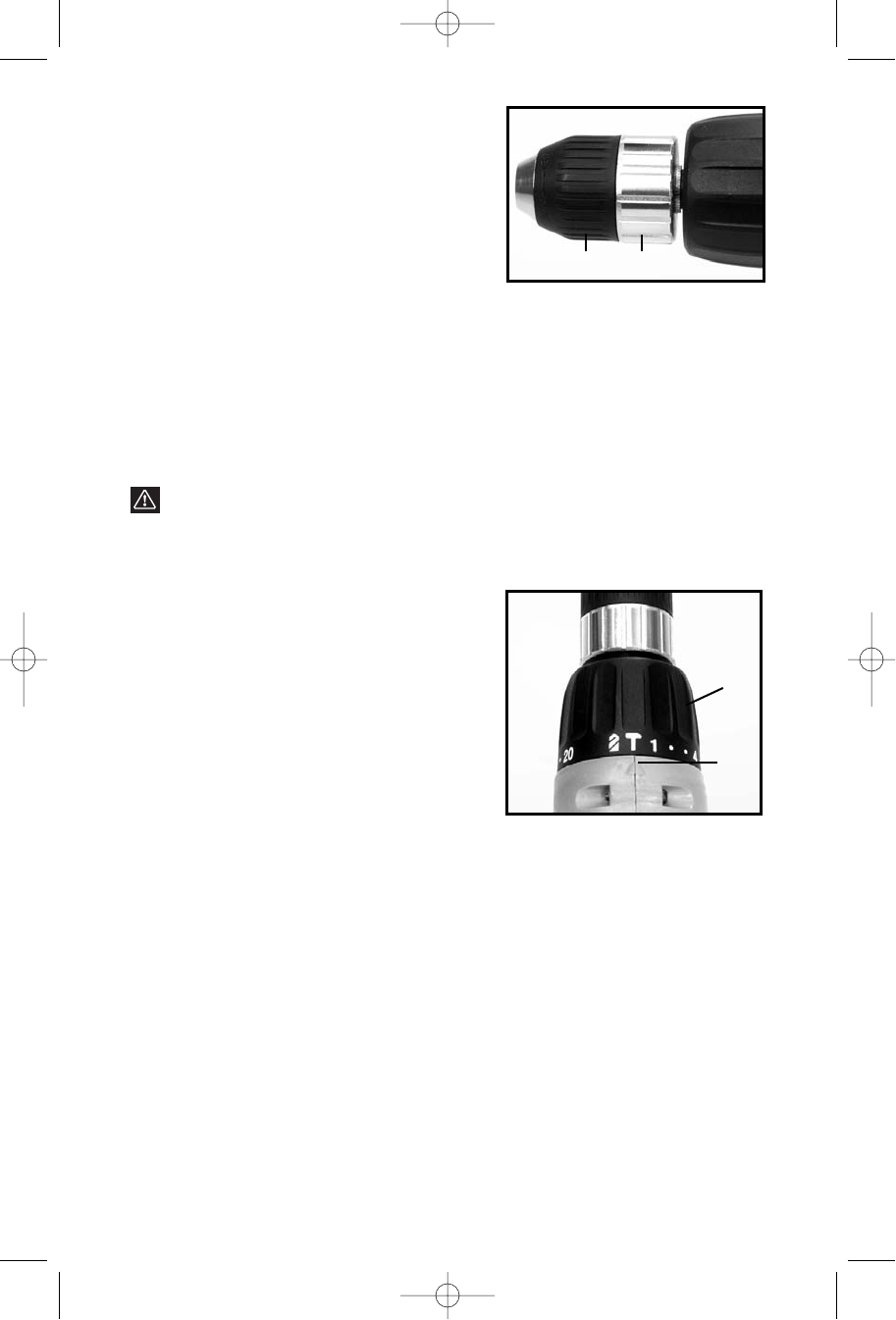

ADJUSTING TORQUE COLLAR

The clutch unit provides twenty clutch

settings, a “Drill” (solid lock-up) setting, and

a hammer (impact) position. Lowest torque is

avaible at setting #1, with maximum torque

available at the “Drill” setting. The amount of

output torque may be adjusted by rotating

the front collar (A) Fig. 3, so that the desired

torque setting is aligned with the index mark

(B) Fig. 3. In general, lower torque settings

are used for driving small screws and other

delicate work, while higher torque settings

are used for driving larger screws. The “Drill” position is used for drilling and for

driving very large screws. The hammer position is used when “impacting” is

needed to assist in the drilling operation such as when drilling in concrete,

bricks, etc.

TWO-SPEED GEAR SHIFT

The Models 877 and 887 Cordless Hammer Drill/Drivers have a two-speed

gear shift which provides spindle speed ranges of approximately: 0 to 475

RPM (LOW) and 0 to 1450 RPM (HIGH) for Model 877; 0-500 RPM (LOW) and

0-1500 RPM (HIGH) for Model 887. To change speed ranges: release trigger

switch to stop motor and then slide speed selector (A) Fig. 4, toward rear for

HIGH speed or toward front for LOW speed.

The low speed position is normally used when drilling larger holes and when

driving or removing screws. The high speed position is normally used for

drilling small holes.

Fig. 2

AB

Fig. 3

A

B

900470 - 11-30-00.QXD 9/25/02 11:09 AM Page 7